Fuel supply control system for engine

A technology of fuel supply and control system, applied in the direction of charging system, engine components, machine/engine, etc., to ensure the starting performance and prevent shrinkage and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will now be described by way of preferred embodiments with reference to the accompanying drawings.

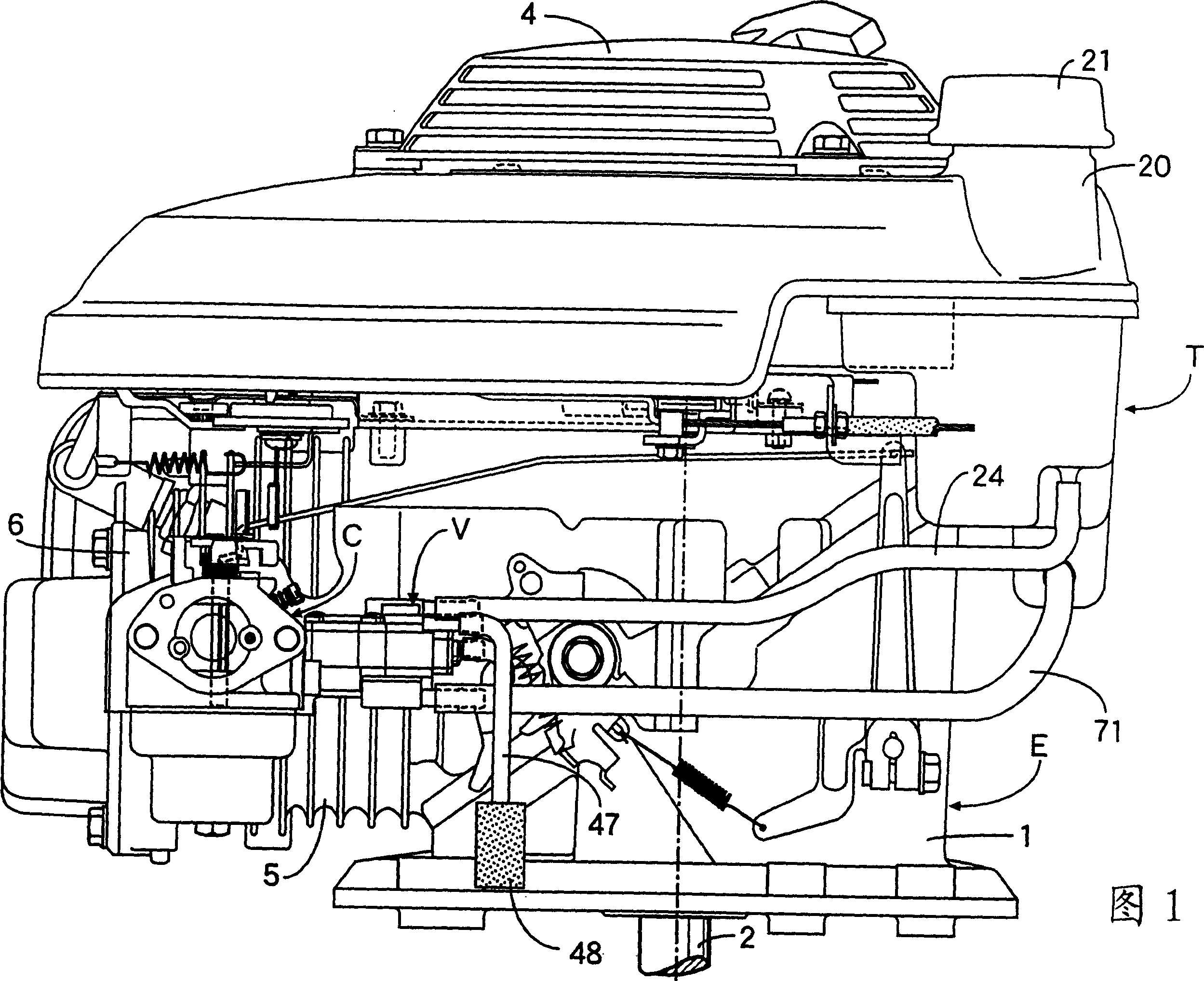

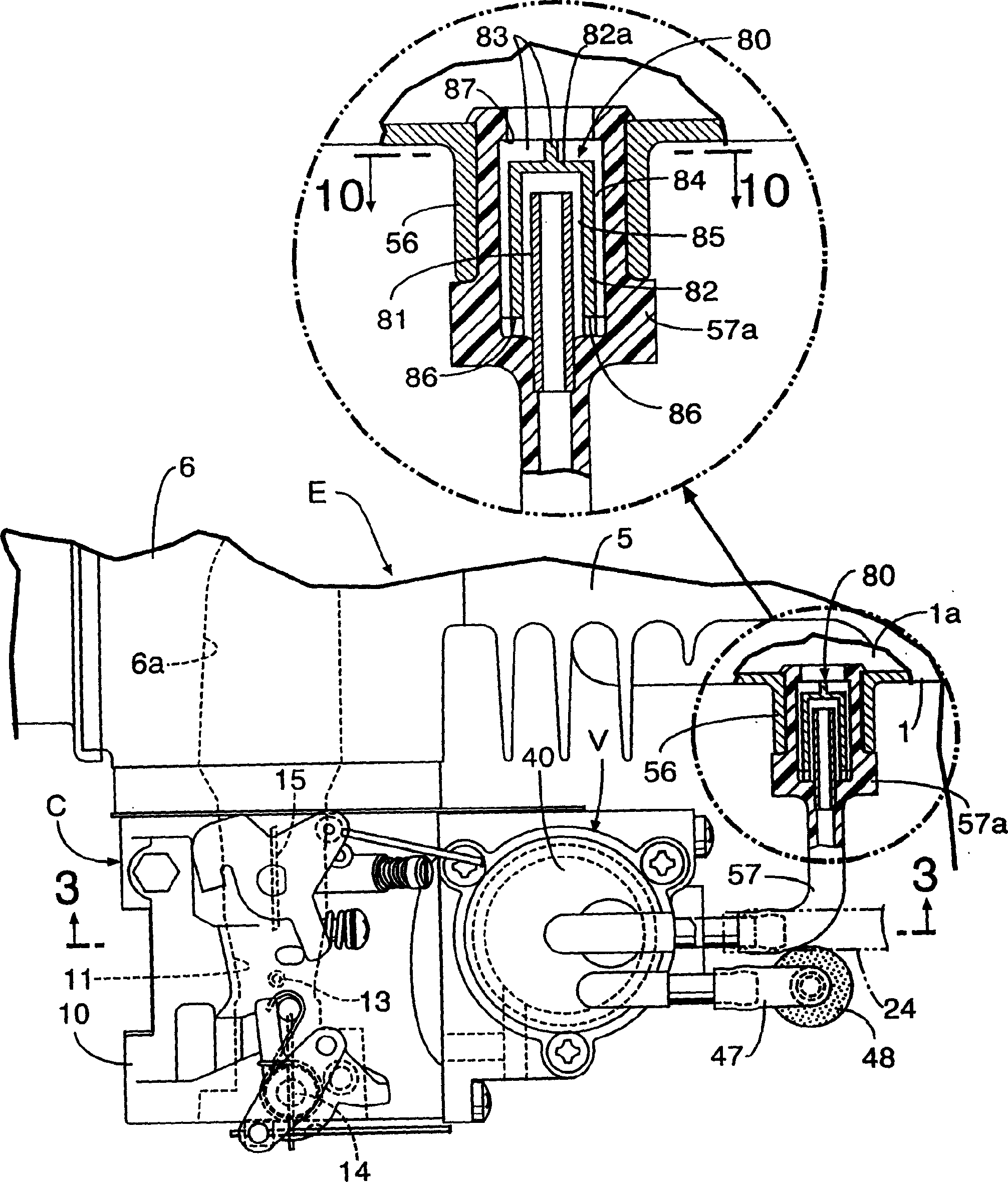

[0037] First, a first embodiment of the present invention shown in FIGS. 1-11 will be described. In FIGS. 1 and 2, reference numeral E denotes a 4-stroke vertical type general-purpose engine. The crankshaft 2 supported in the crankcase 1 of the engine E is arranged vertically, and its output end protrudes downward to the bottom of the crankcase 1 . A fuel tank T and a recoil starter 4 are attached to the upper portion of the crankcase 1 .

[0038] A cylinder block 5 having a horizontally arranged cylinder axis is connected to one side of the crankcase 1 , and a carburetor C is mounted to one side of a cylinder head 6 coupled to an end of the cylinder block 5 .

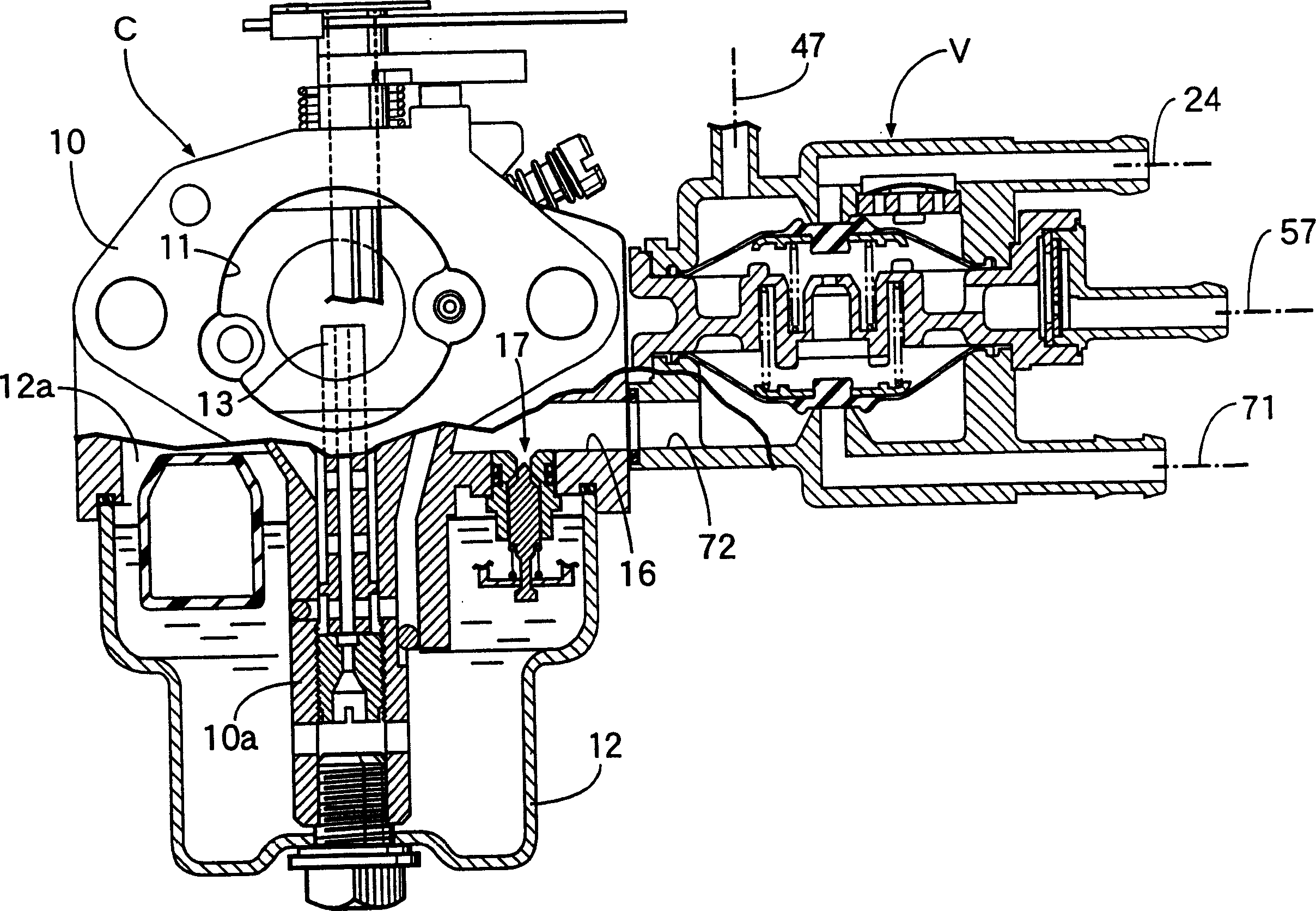

[0039] refer to image 3, the carburetor C includes: a carburetor body 10, which has an air intake passage 11 leading to the air intake port 6a of the cylinder head 6; a floating chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com