Device for delivery metal coil tape on tray

一种金属带、托盘的技术,应用在运输和包装、金属轧制、金属轧制等方向,能够解决温度高等问题,达到降低变形影响的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

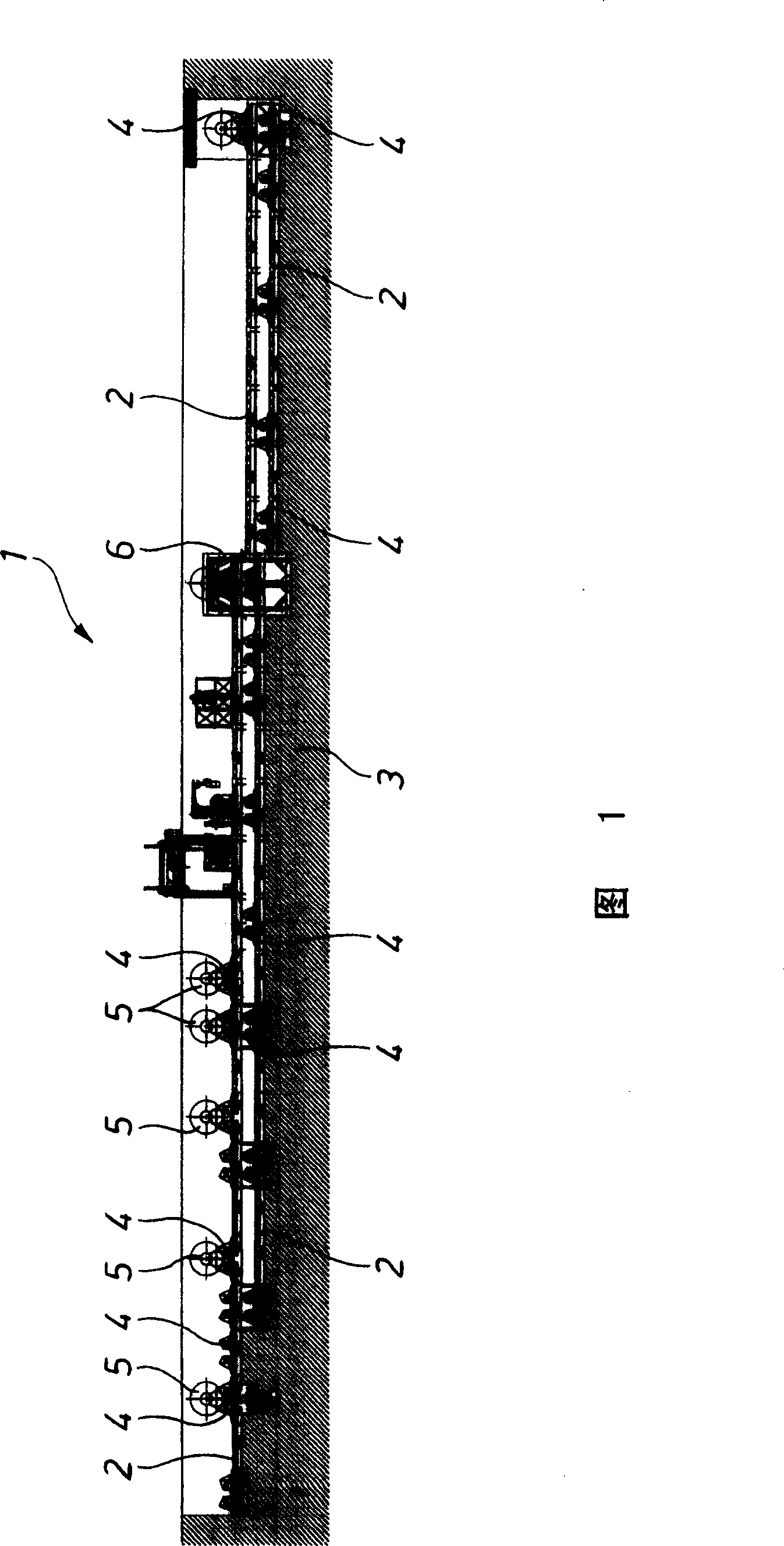

[0032] figure 1 Partially shown in , the pallet circulation system 1 used in rolling mills for the production of metal strips here includes transport sections 2 which are arranged at different height levels in the foundation 3 . On this transport section 2 , the hot strip 5 wound into a coil or metal strip after rolling is transported and distributed by means of pallets 4 , in particular to a subsequent processing station. A number of workstations are shown for the coils 5 of hot tape received by the tray 4 . A lifting frame 6 integrated into the transport section 2 is used for distribution at different height levels.

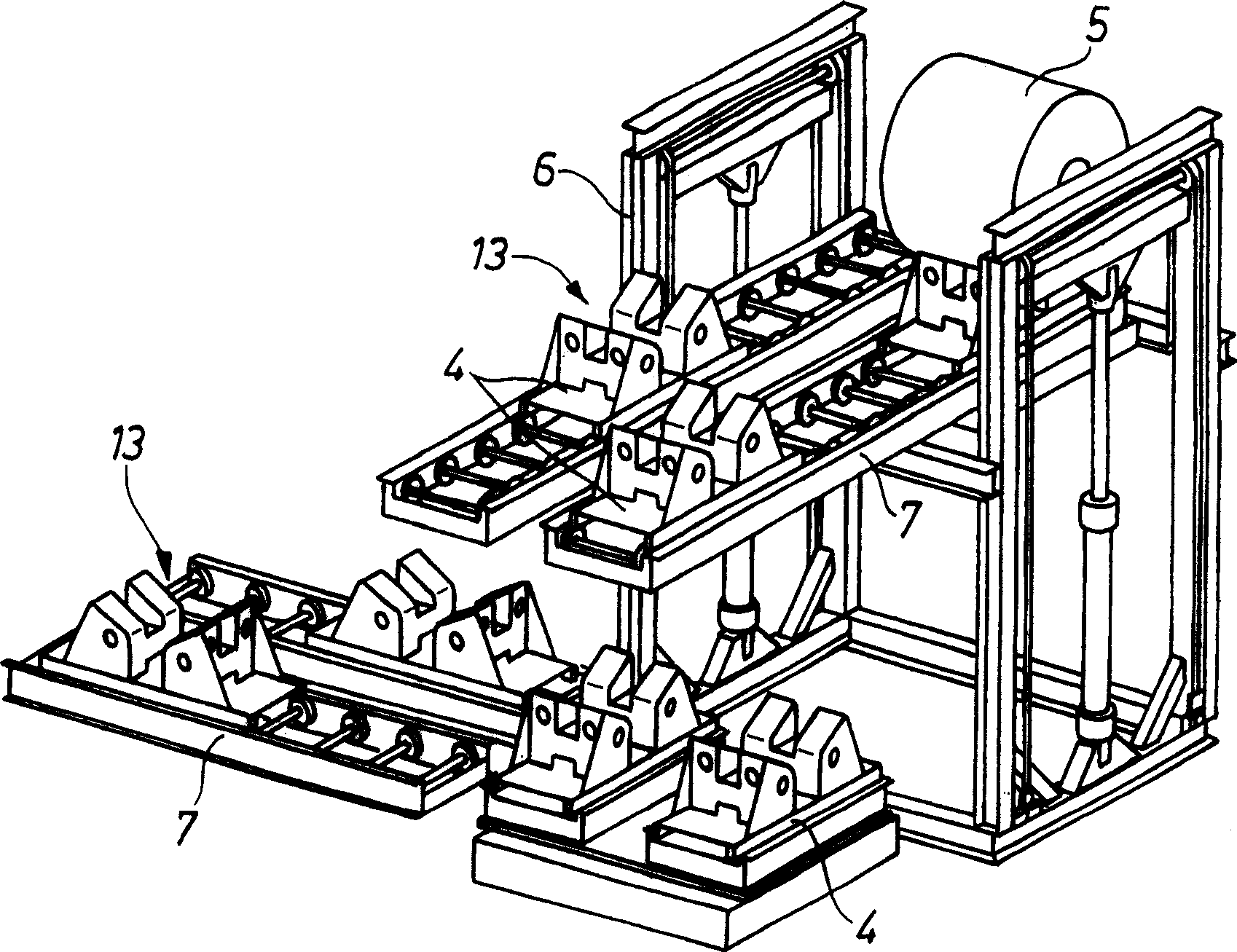

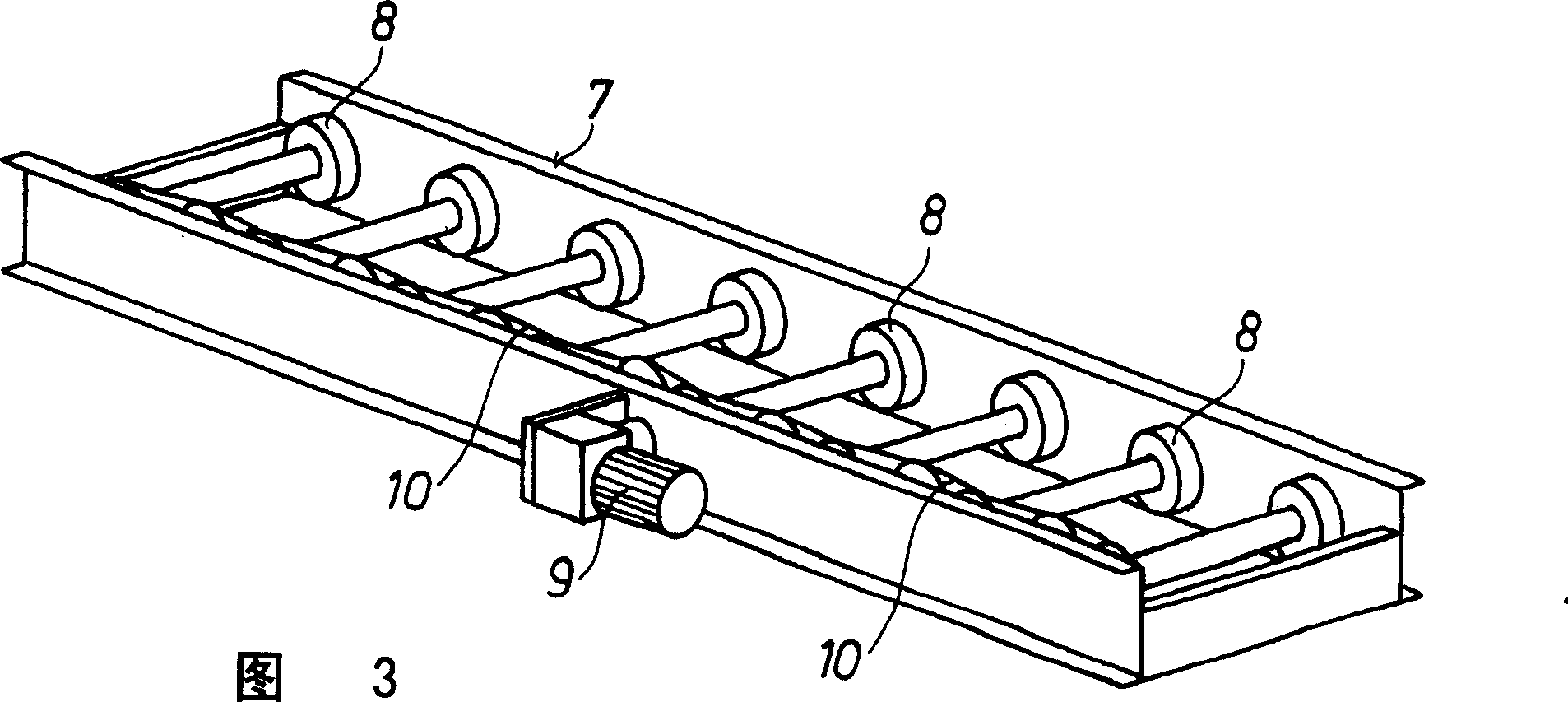

[0033] Lift Rack 6 by figure 2 It can be seen in detail that, according to this figure, a plurality of trays 4 are arranged on the upper and lower roller table sections 7 , one of which is equipped with a heat strip 5 in the exemplary embodiment. The roller table section 7 has a large number of rollers 8, which are driven by a centralized drive motor 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com