Thick-layer self-leveling mortar

A self-leveling mortar and sand technology, applied in the field of mortar, can solve the problems of self-leveling mortar hydration shrinkage cracking, large pouring thickness, uneven hydration, etc., and achieve the effect of improving surface effect, increasing early strength, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 Composition of a kind of thick layer self-leveling mortar

[0021] 371kg of cement; 156kg of sulfur-aluminum cement; 48kg of anhydrite; 425kg of sand; 1.15kg of water reducing agent; 0.63kg of HPMC; 0.0025kg of air-entraining agent; kg; sodium gluconate 0.15kg; tartaric acid 0.55kg; lime calcium 14kg.

Embodiment 2

[0022] Embodiment 2 selects the optimal ratio of magnesium aluminum silicate

[0023] a. Taking Example 1 as an example, change the ratio of magnesium aluminum silicate to study the influence of different dosages of magnesium aluminum silicate on the fluidity of thick layer self-leveling mortar

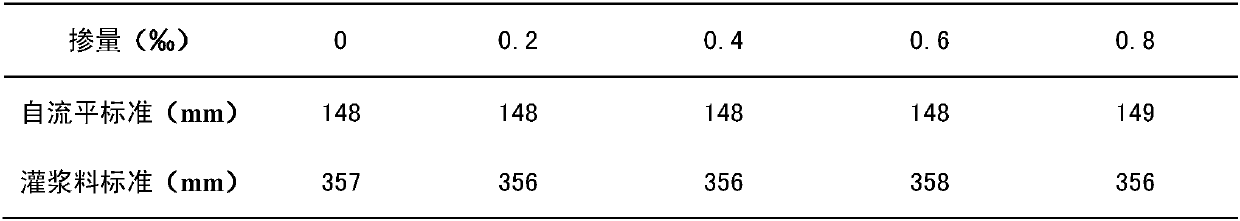

[0024] Table 1 Influence of magnesium aluminum silicate content on fluidity

[0025]

[0026] It can be clearly seen from Table 1 that with the increase of the amount of inorganic thickener magnesium aluminum silicate, the fluidity does not decrease or increase, so magnesium aluminum silicate has no obvious effect on the fluidity of self-leveling mortar. Influence; And the present invention has studied the effect of inorganic thickener magnesium aluminum silicate on the surface of self-leveling mortar as can be seen obviously, inorganic thickener magnesium aluminum silicate has significant effect for improving the surface of thick layer self-leveling mortar, when When the dosage i...

Embodiment 3

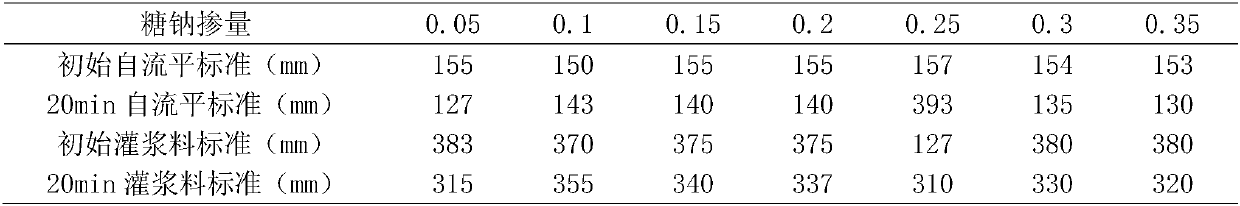

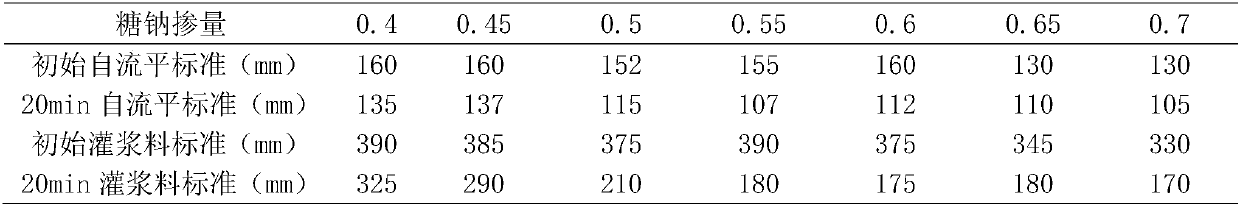

[0030] Example 3 Effect of different retarding components on the performance of thick self-leveling mortar

[0031] This embodiment is based on the composition of thick-layer self-leveling mortar in Example 1, changing the ratio of sodium gluconate and tartaric acid to study the influence of different retarding components on the performance of thick-layer self-leveling mortar.

[0032] When sodium gluconate is used alone as a retarder, the effect is not very obvious. It is usually used in combination with other retarders. At the same time, sodium gluconate also has a certain water-reducing effect. Under the circumstances, the fluidity of the mortar can be improved. Therefore, when compounding with tartaric acid, it is appropriate to reduce the total amount of retarder to 0.70% to prevent bleeding and segregation. Because sodium gluconate is more sensitive to the influence of fluidity, therefore, the content of sodium gluconate is gradually increased by 0.05% until completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com