Commutator motor

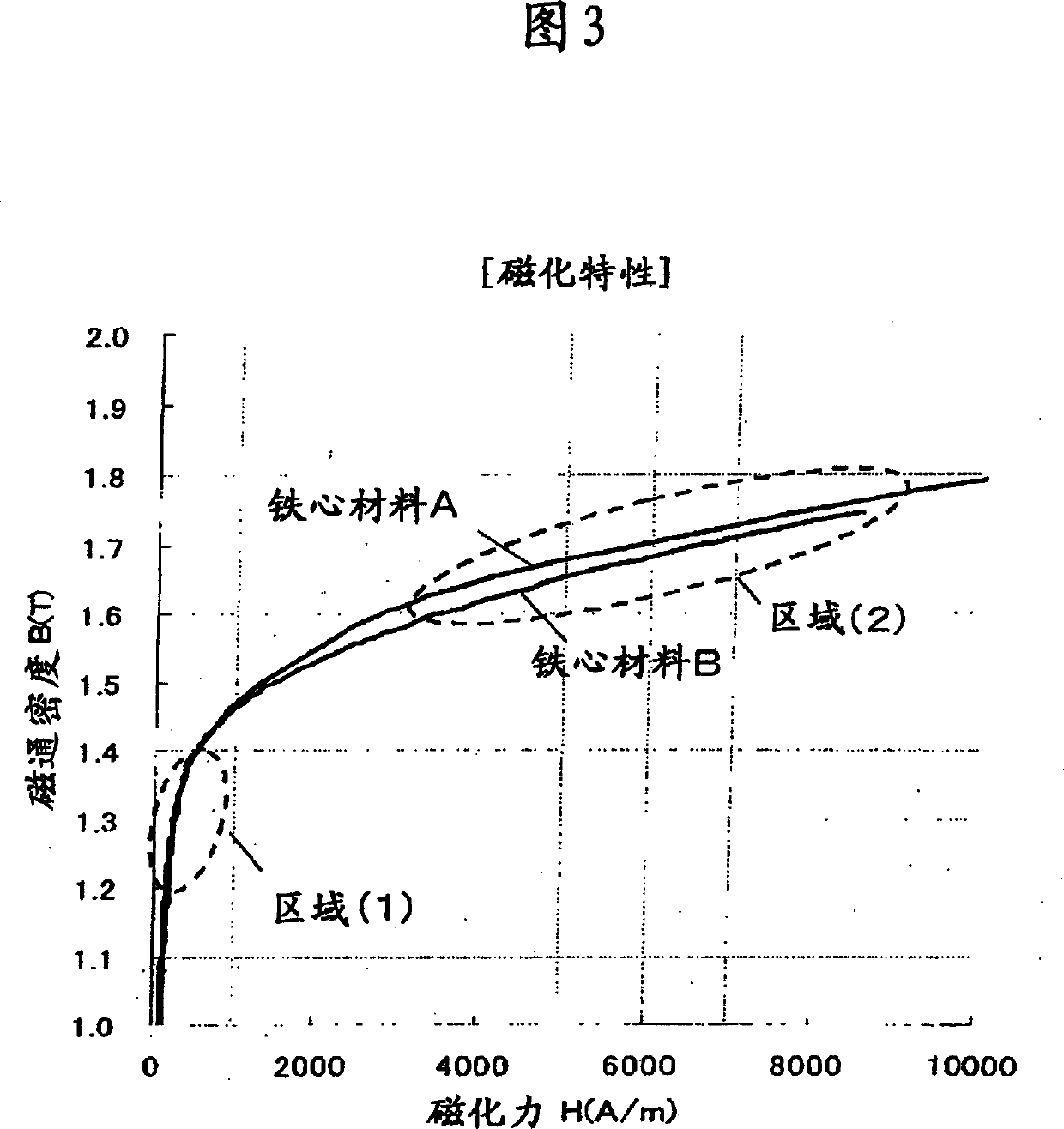

A technology of electric motor and commutator, which is applied in the field of iron core composition of commutator motor, can solve the problems such as difficulty in reducing copper loss, improving efficiency, reducing cross-sectional area, etc., and achieves the effect of reducing iron loss and suppressing the increase of excitation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

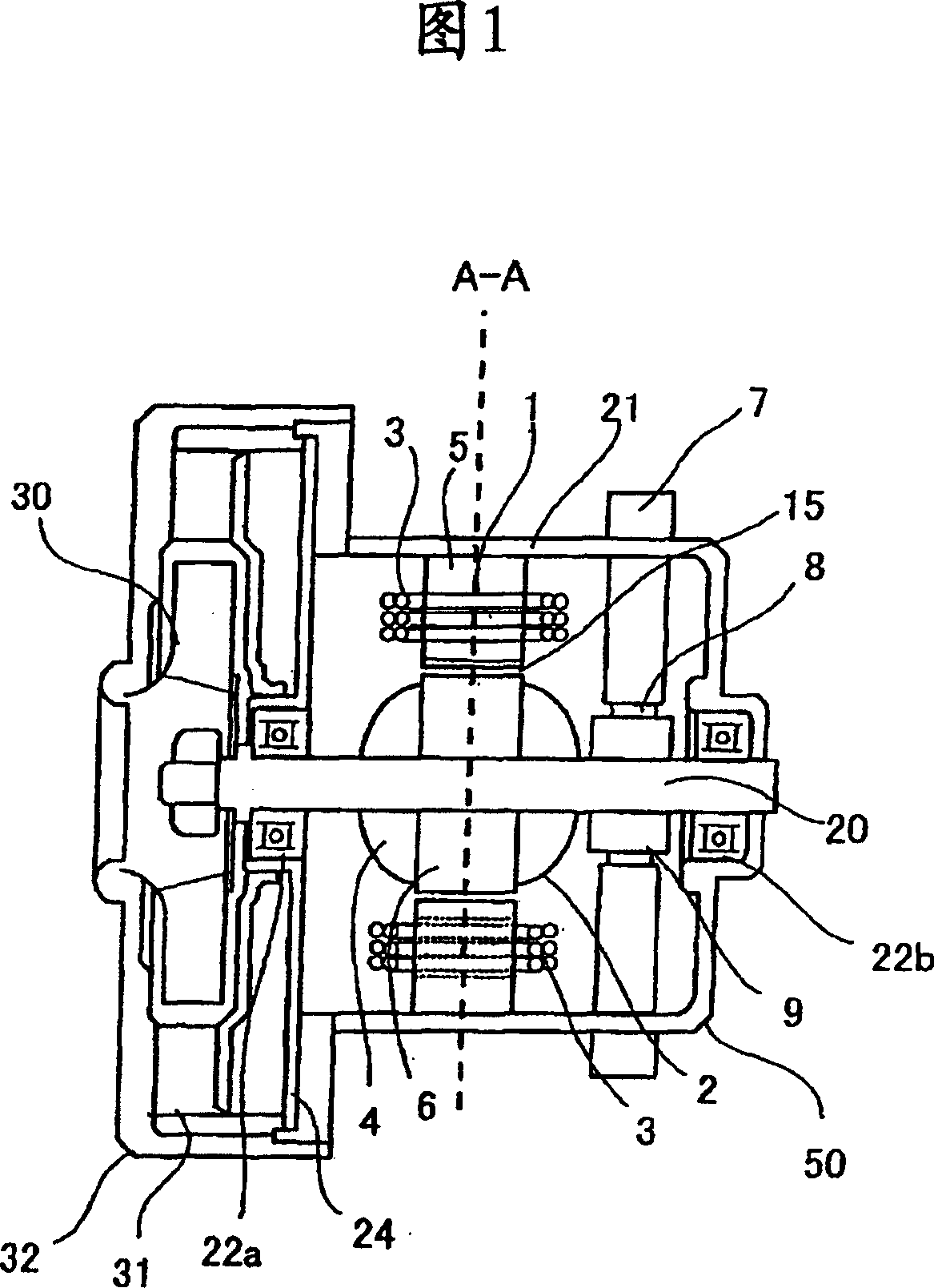

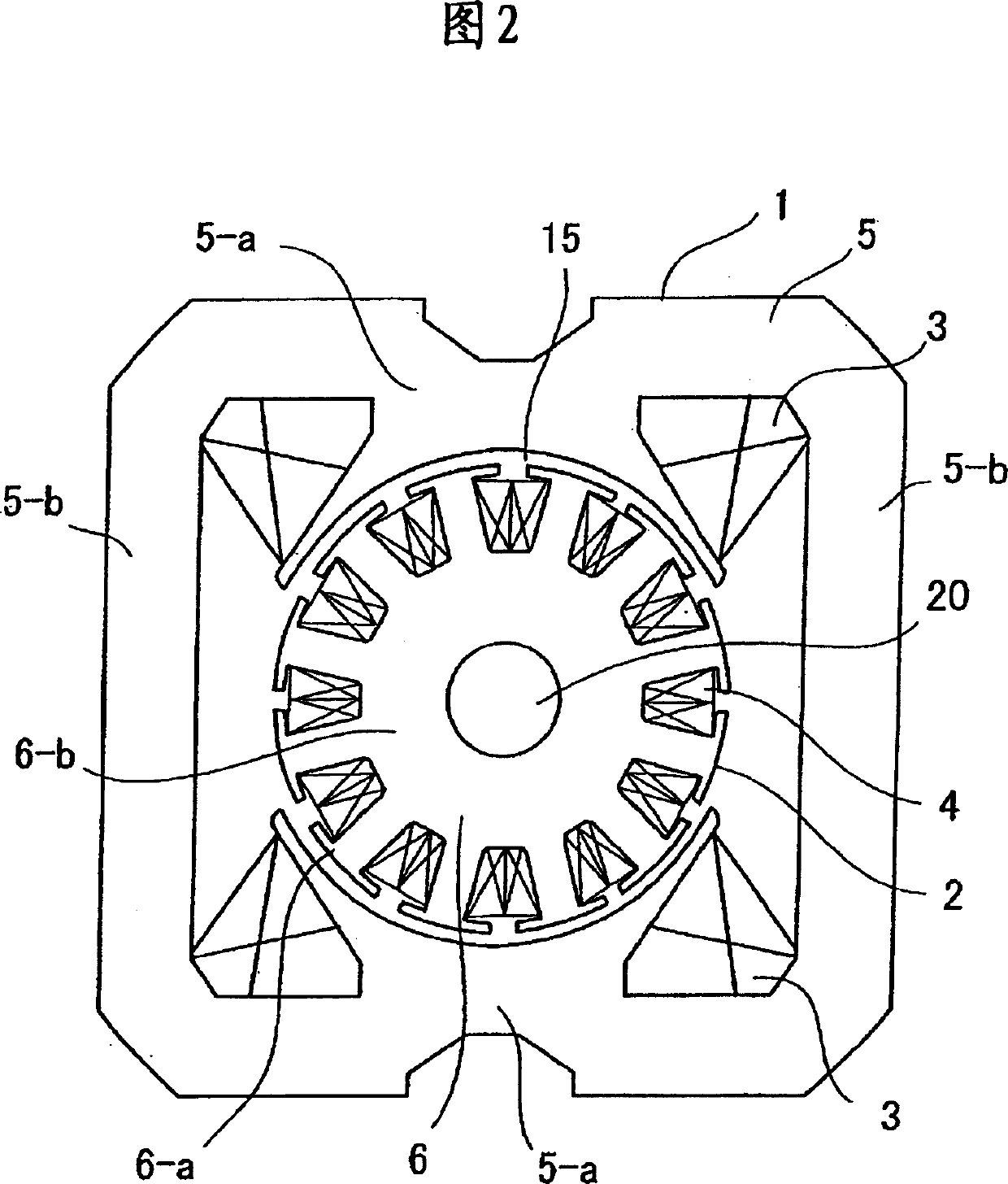

[0022] Hereinafter, an example of the embodiment of the present invention will be described based on FIGS. 1 to 6.

[0023] Fig. 1 shows an embodiment of the structure of the electric blower of the present invention. The motor side of the electric blower 50 is composed of the armature 2 and the stator 1 in the housing 21 and the end bracket 24. In addition, a diffuser 31 and a housing 32 are provided to surround the fan 30 provided at the end of the output shaft of the motor.

[0024] The stator 1 of the electric motor is composed of a stator core 5 and a field coil 3 in a housing 21, and a main magnetic flux is generated by the field magnetomotive force by passing a current through the field coil 3. The armature 2 arranged with a gap 15 from the stator core 5 has a shaft 20 supported by bearings 22a and 22b provided on the shaft of the housing 21 and the end bracket 24. The shaft 20 is provided with a commutator 9 and an armature core 6. The armature coil 4 is wound around the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com