Method for direct preparation of polyaniline solution from aniline monomer

A kind of technology of aniline monomer and polyaniline, which is applied in the field of directly preparing polyaniline solution by using aniline monomer, can solve the problems of complex post-processing procedures, low doping efficiency, and difficult control of conductivity, and achieve easy storage, transportation, and production The effect of simple process and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

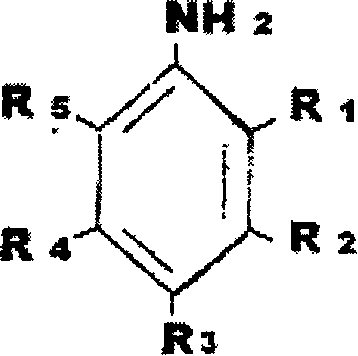

Image

Examples

Embodiment 1

[0026] Take 2.04g of aniline monomer, 8.58g of dodecylbenzenesulfonic acid, 100ml of xylene, and 400ml of deionized water into the reaction kettle, and stir vigorously for 1 hour to form milk. Continue stirring, and slowly add 5.5g of ammonium persulfate (10 % solution), reacted at room temperature (25° C.) for 5 hours, after the reaction was finished, 200 ml of acetone was added dropwise to break the emulsion, stood still for 1 hour, separated, the organic phase was washed with 200 ml of deionized water, and the aqueous phase was separated, and the organic phase was containing 4.32% polyaniline dark green stable solution, after evaporation and recovery of 50ml of xylene, a polyaniline solution containing 8.64% was obtained, continued evaporation and recovery of xylene until nearly dry, dried in an oven at a temperature of 60°C to a constant weight to obtain 4.32g of dark green DBSA-doped polyaniline. The conductivity of the doped polyaniline measured in a four-electrode condu...

Embodiment 2~6

[0028] Example

Embodiment 7~9

[0030] Change the add-on of aniline, change the organic solvent that adds, respectively use 100ml of N-methylpyrrolidone, N, N-dimethylformamide and carbon tetrachloride, others are the same as Example 1, the results are shown in the following table. As can be seen from the table, with N,N-dimethylformamide as solvent, its yield is higher than that of other solvents, but the electrical conductivity is all lower than other example products.

[0031] Example (solvent)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com