Method and its device for ring spindle yarn multiple head spinning

A multi-end spinning and spun yarn technology, which is applied to spinning machines, textiles and papermaking, and continuous winding spinning machines, etc., can solve the problem of affecting weaving production efficiency and product quality, restricting the production of high-grade light and thin fabrics, and failing to produce qualified fabrics. Product and other problems, to achieve the effects of saving production processes, improving evenness, and improving friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

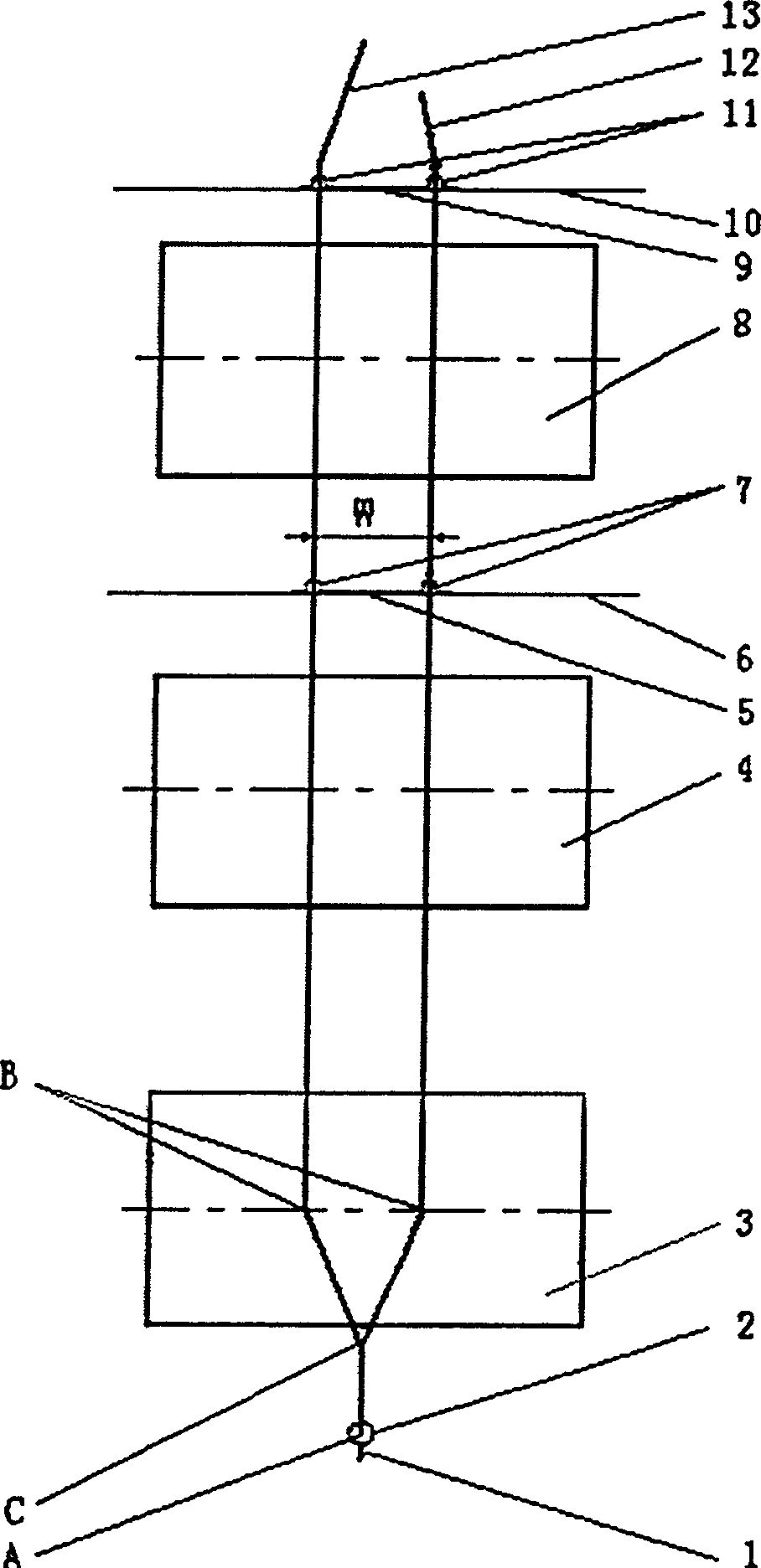

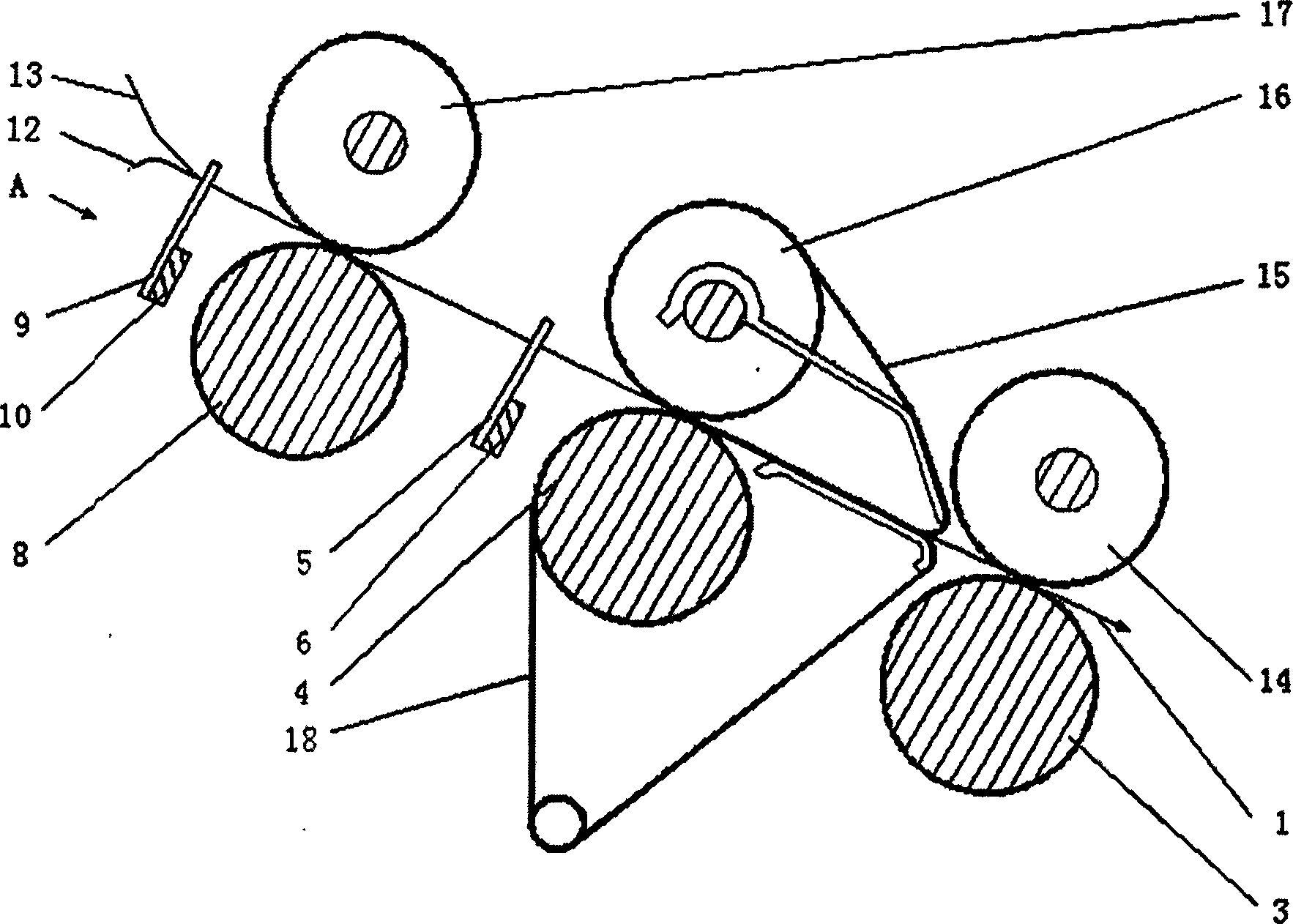

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

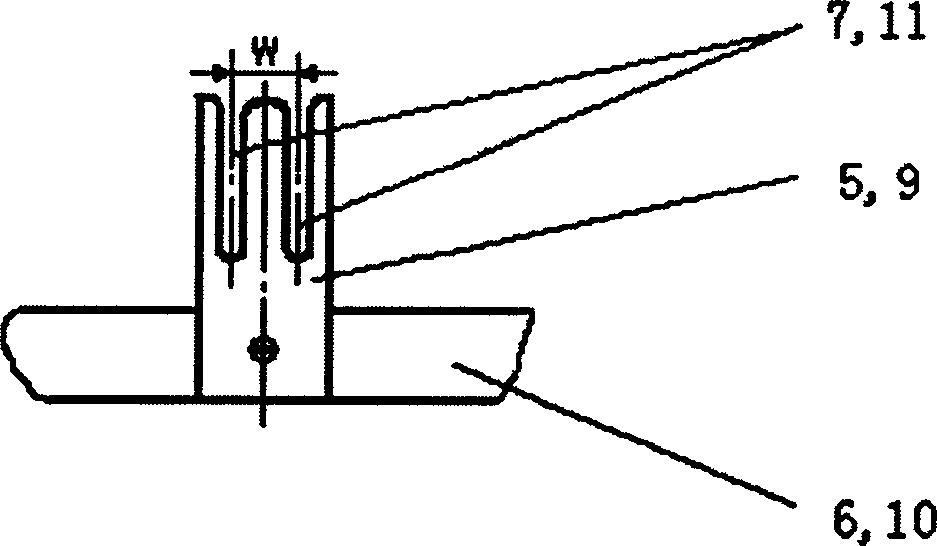

[0018] The multi-end spinning process of the spindle spun yarn proposed by the present invention is based on the ordinary ring spinning frame, and adopts single-spindle multi-head roving feeding, that is, adopts a group of two or more rovings, and each roving can come from the same or Different roving bobbins pass through the rear yarn guide, and each roving is fed from the rear roller and top roller at equal or unequal feeding intervals, then through the middle yarn guide, through the front roller and the top roller. The rollers and aprons carry out multi-head drafting, lead out from the front rollers and top rollers, enter the twisting zone for twisting, and then pass through the front yarn guide to further complete twisting and winding. In order to realize the processing method of the present invention, the relevant mechanism of the traditional ring spinning frame m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com