Pure dry type fluorosilicon integrated high pressure passing wall bushing

A high-voltage wall-piercing bushing, fluorine-silicon technology, applied in the direction of electrical components, etc., can solve the problems of easy lateral displacement of the internal insulating medium, tearing of aluminum film electrodes, explosion of faulty parts, etc., to eliminate internal defects and bonding problem, partial discharge and dielectric loss reduction, and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

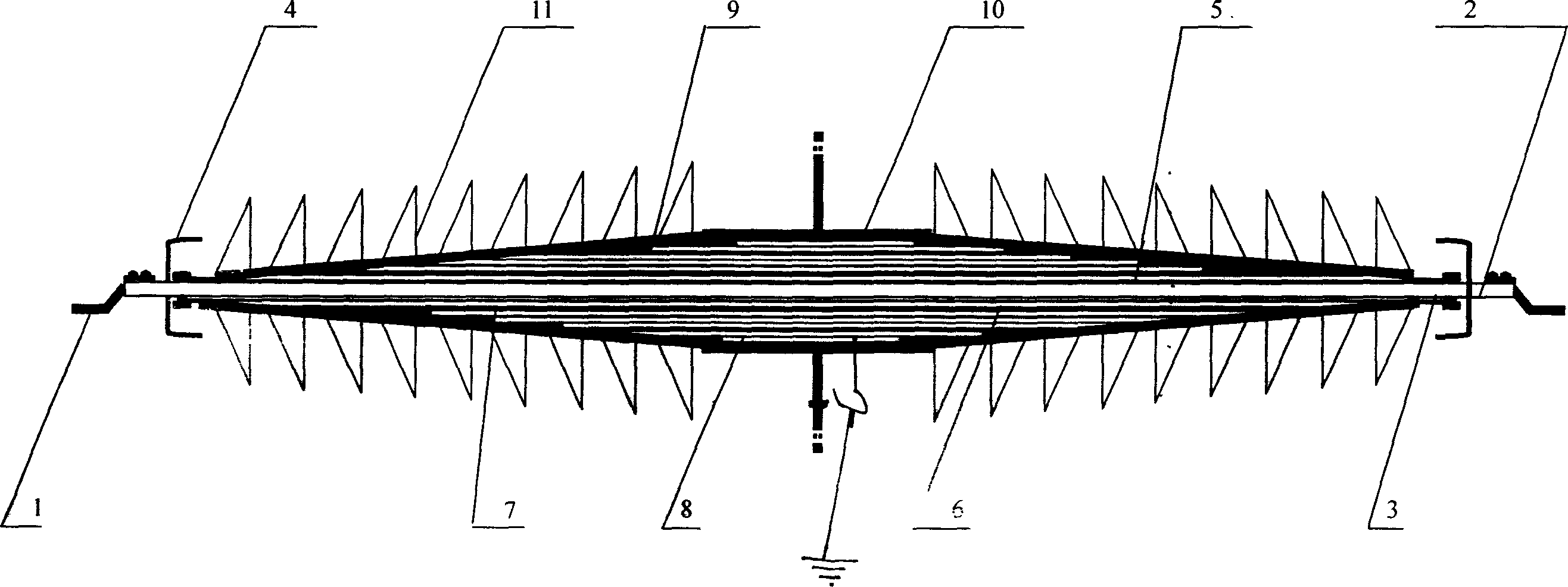

[0008] As shown in the attached figure, the conductive rod 2 is fixed inside the stainless steel tube 3, and one end is equipotentially connected to the stainless steel tube 3, the connecting terminal 1 is fixed at both ends of the conductive rod 2, the pressure equalizing cover 4 is fixed at both ends of the stainless steel tube 3, and the middle is a fluorosilicon semi-conductor. Conductive adhesive buffer layer 5. Several cylindrical aluminum thin electrodes 6 are arranged at intervals along the axial direction outside the buffer layer 5, and the intervals are the main insulating layer 7, which is filled with fluorosilicone rubber. Ground screen 8 leads ground wire, uses fluorosilicone rubber as outer protection layer 9, and flange 10 is fixed in the middle of outer protection layer 9; The fluorosilicone semiconductive adhesive is a semiconductive adhesive compounded from fluorosilicone rubber and high-resistance fillers, with a resistivity of 10 4 -10 6 Ω·M. The fluoros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com