Pressure opening and closing valve

A technology of pressure switch and valve body, applied in the field of pressure switch valve, can solve the problems of beating, difficult to prevent noise, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

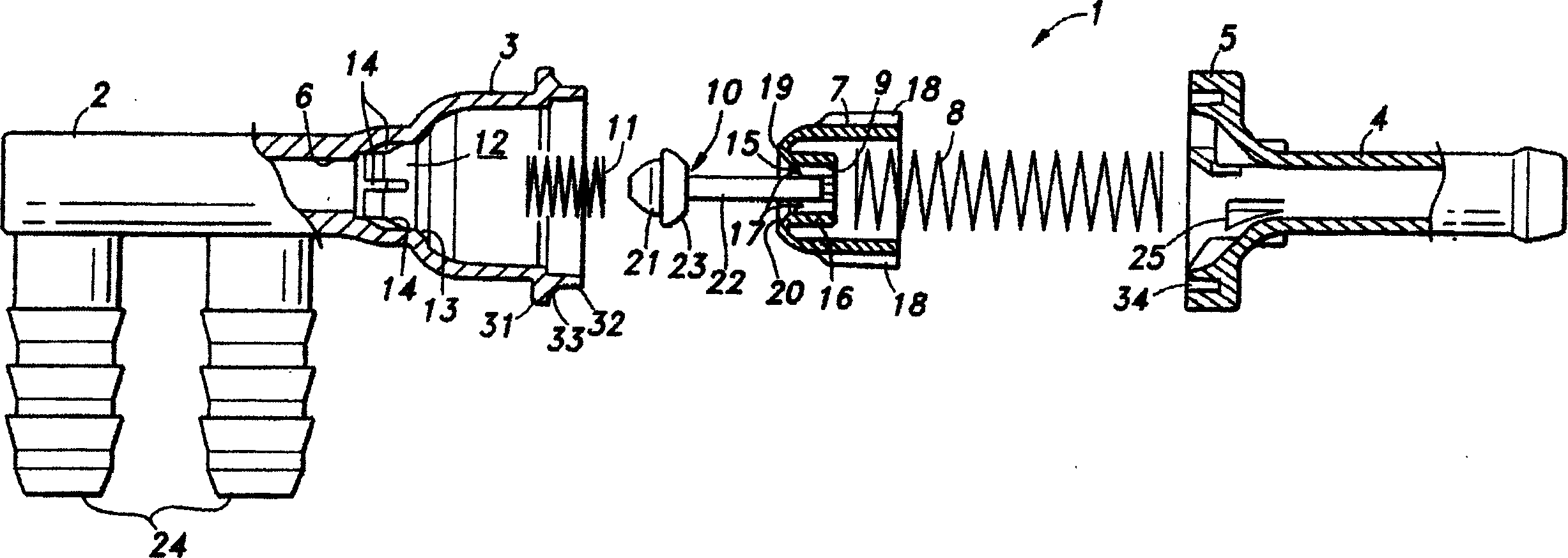

Image

Examples

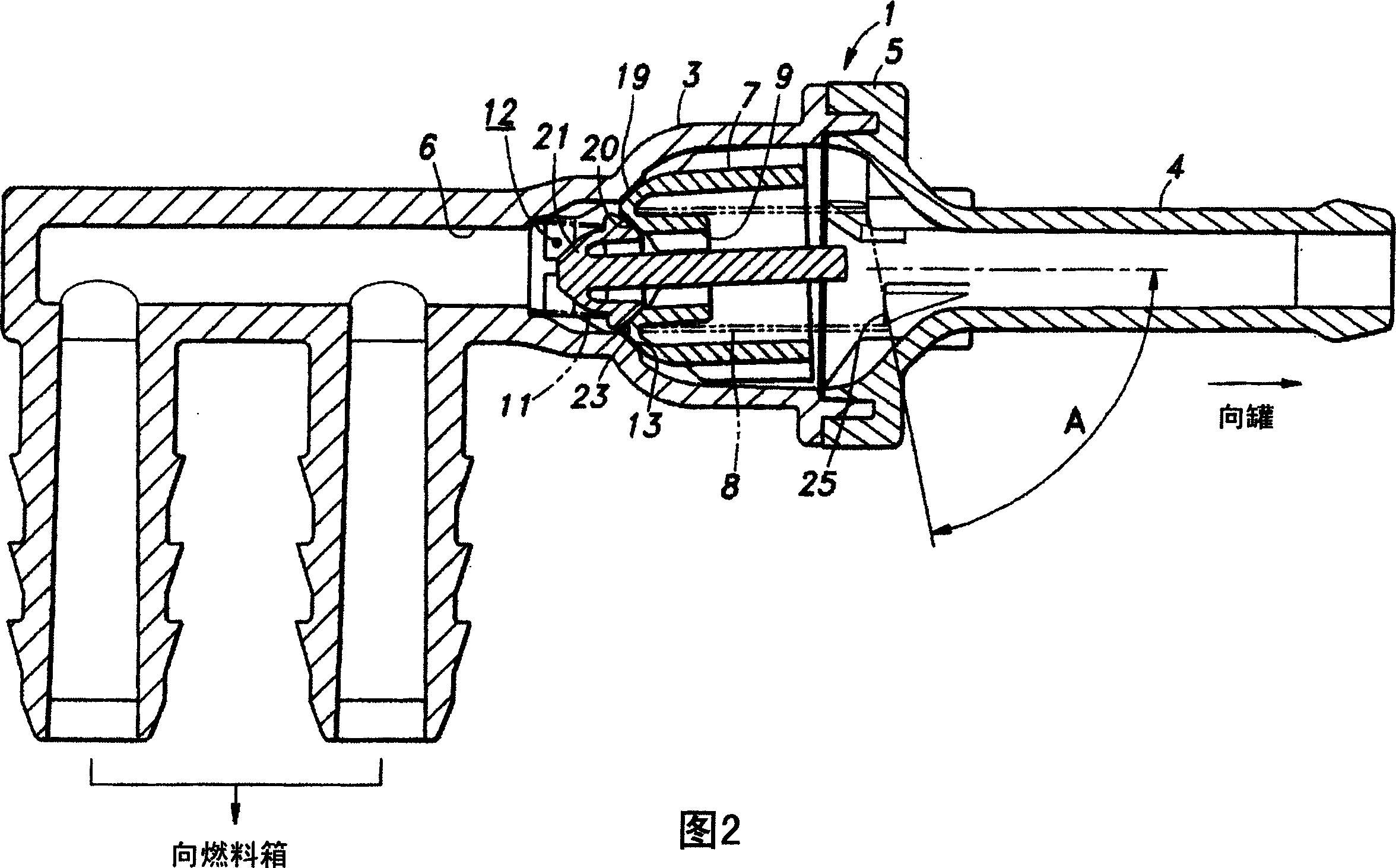

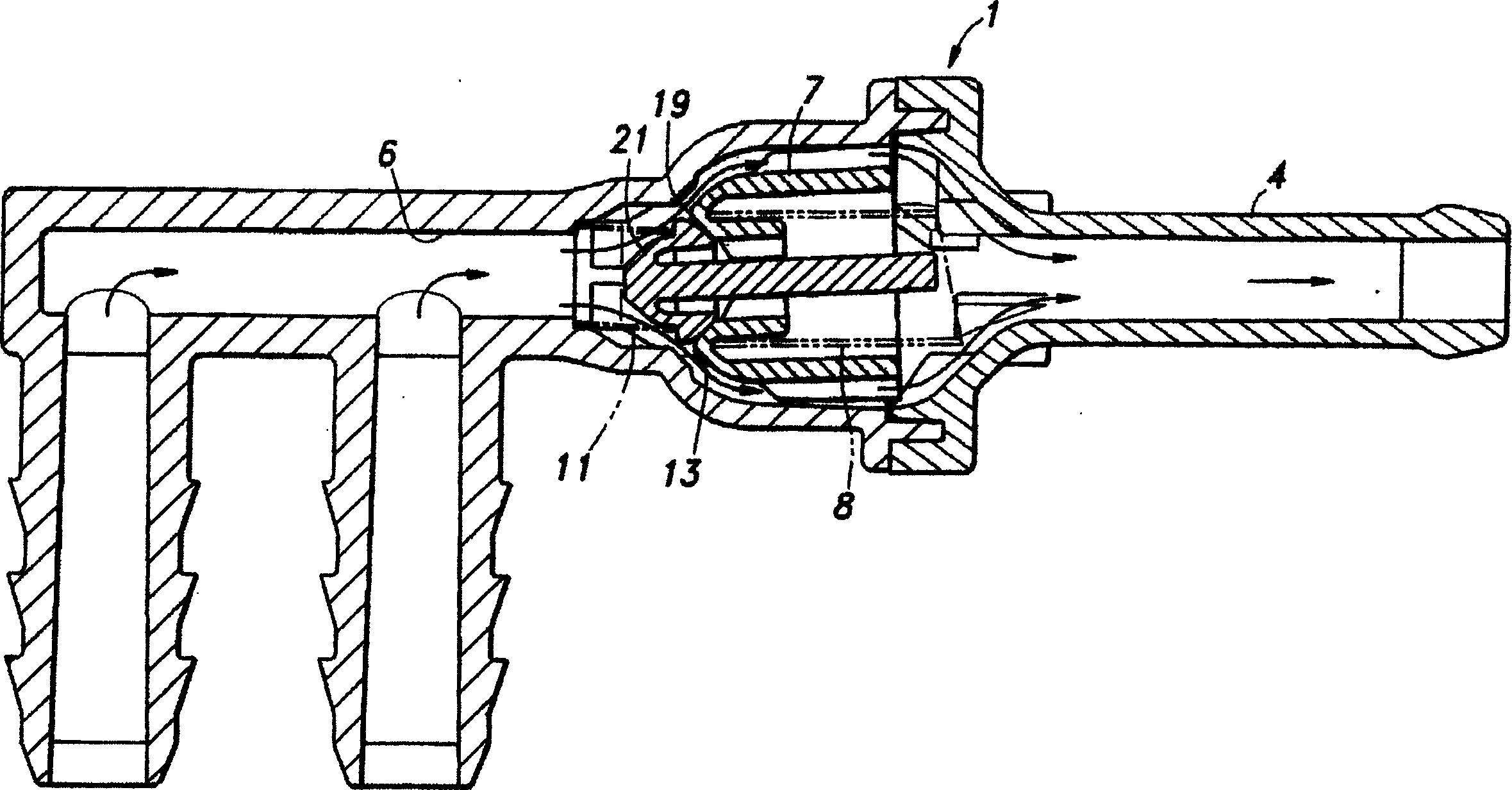

Embodiment 1

[0045] In the pressure switch valve 1 described above, the contact surface with the tip of the large-diameter coil spring 8 of the spring support portion (spring seat) 25 provided on the case cap 5 is arranged so as not to be perpendicular to the central axis of the case main portion 3 Intersect and set to a suitable inclination angle A. Therefore, the central axis of the large-diameter coil spring 8 in the natural state is not parallel to the central axis of the housing main part 3, that is, with respect to the axis of the positive pressure valve seat 13 formed in the central part of the housing main part, The central axis of the large-diameter coil spring 8 is inclined at an appropriate angle. Therefore, when the positive pressure valve body 7 is installed in the housing main part 3 while compressing the large diameter coil spring 8 , the elastic force direction of the large diameter coil spring 8 is not parallel to the axis of the positive pressure valve body 13 . That is,...

Embodiment 2

[0047] Figure 5 Another method for inclining the axis of the valve-opening elastic force applied to the positive pressure valve body 7 is shown. A coiled large diameter coil spring 26 with the axis inclined in the natural state is used. In this case, the centers of the positive pressure valve seat 13 and the spring support portion 25 are made to coincide with each other, and even if the contact surface with the tip of the large-diameter coil spring 26 of the spring support portion 25 is aligned with the center of the housing main portion 3 The shafts intersect perpendicularly, and when compressing the large-diameter coil spring 26 while installing it between the positive pressure valve body 7 and the spring support portion 25, because of the elastic force for opening the valve of the large-diameter coil spring 26 of the positive pressure valve body 7 The center of the valve seat 13 does not coincide with the center of the positive pressure valve seat 13, so the same effect a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com