Back board for through hole plugging device and assembling method

A device and backplane technology, which is applied in the field of electronic equipment, can solve the problems of small gussets or small inserts that cannot be fixed and has poor reliability, and achieves the effect of engineering design difficulty and engineering cost, easy maintenance, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to which the present invention belongs to understand the present invention more clearly, detailed descriptions will now be given in conjunction with the accompanying drawings.

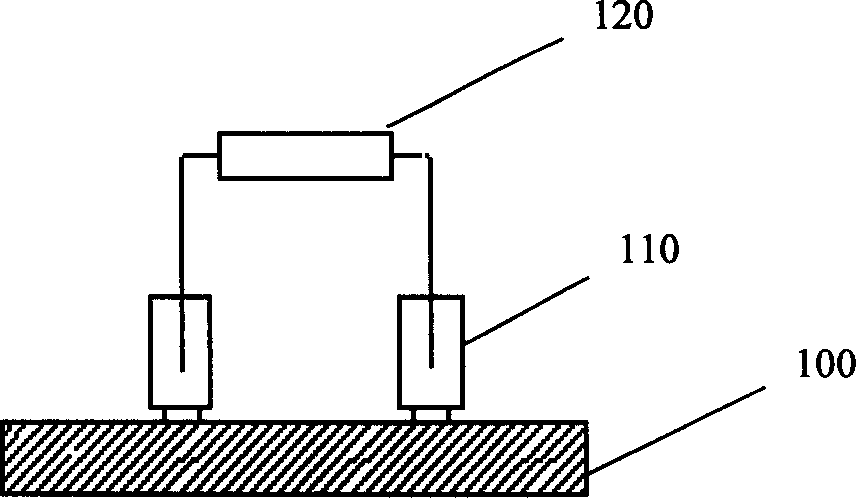

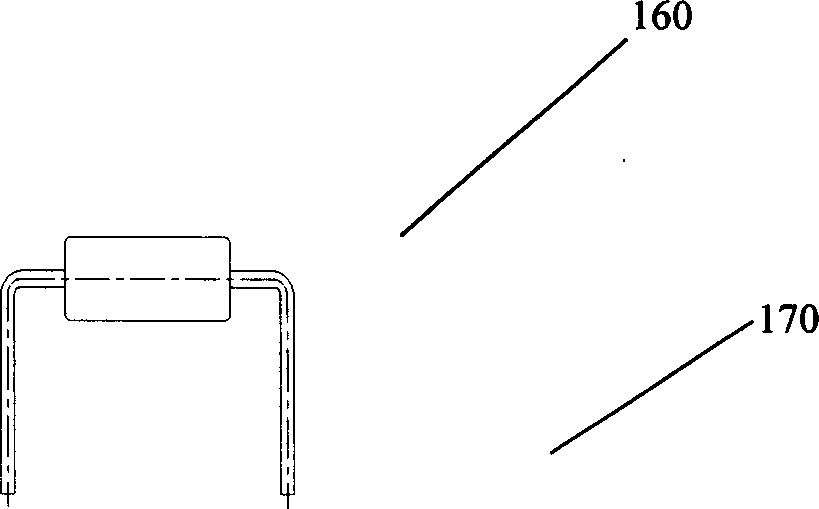

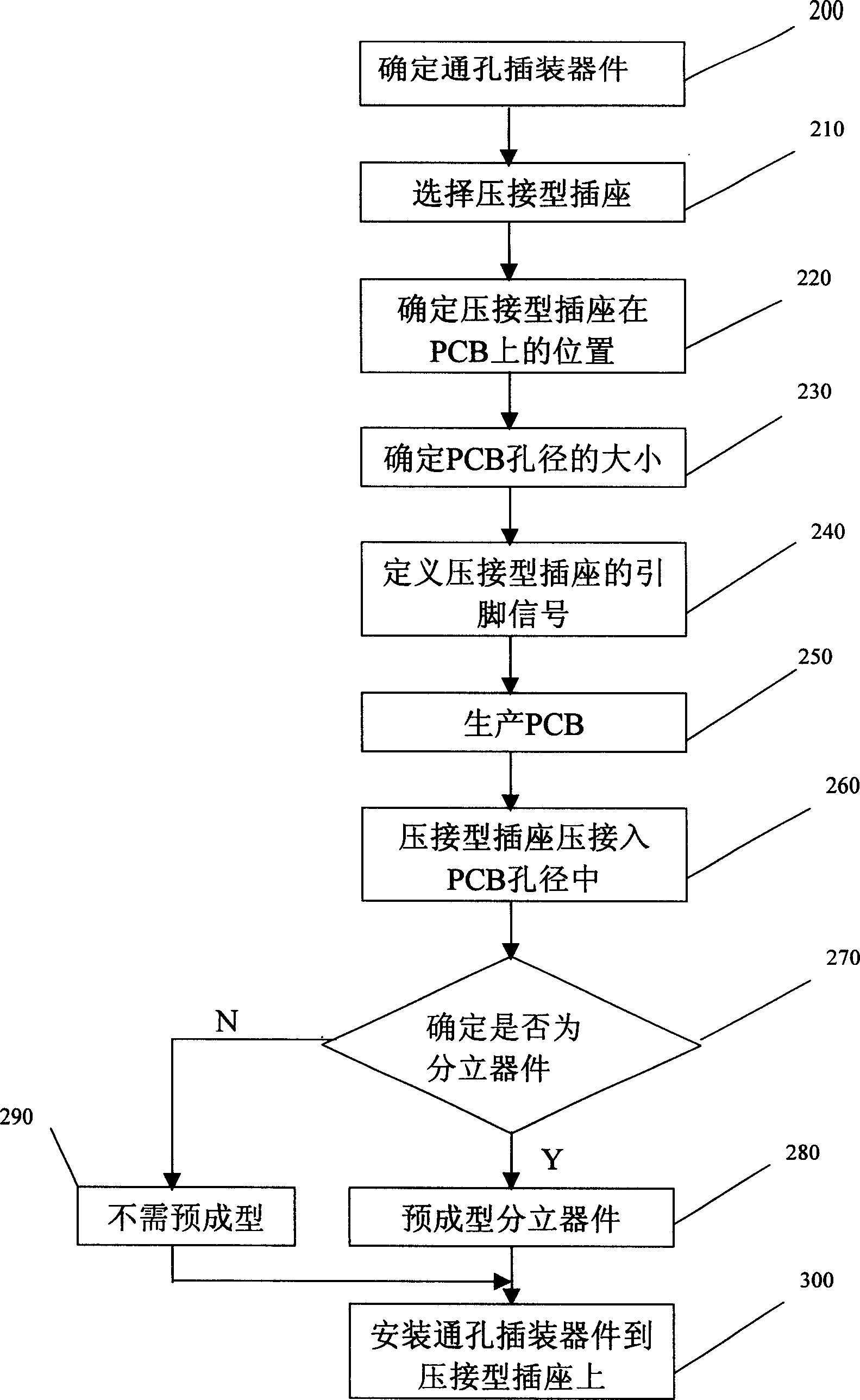

[0038] figure 1 It is a schematic diagram of the backplane with through-hole plug-in devices of the present invention. The backplane with through-hole components includes: PCB 100 , crimp socket 110 and through-hole components 120 . Wherein, the crimping socket 110 is connected to the PCB 100 , and the through-hole device 120 is installed on the crimping socket 110 . The crimp-type pins of the crimp-type socket 110 are crimped in the aperture of the PCB 100 , and the crimp-type pins form an interference fit with the aperture. Through-hole plug-in devices can be discrete devices, such as plug-in resistors, capacitors, light-emitting diodes (LEDs) and other axially packaged devices, or single-in-line package devices (SIP) or dual-in-line packaged devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com