Ink-ejecting acceptance material and back jetting lamp house sheet using the same

An inkjet, box film technology, applied in the direction of copying/marking methods, printing, etc., can solve the problems of non-bright colors, pale images, sticking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

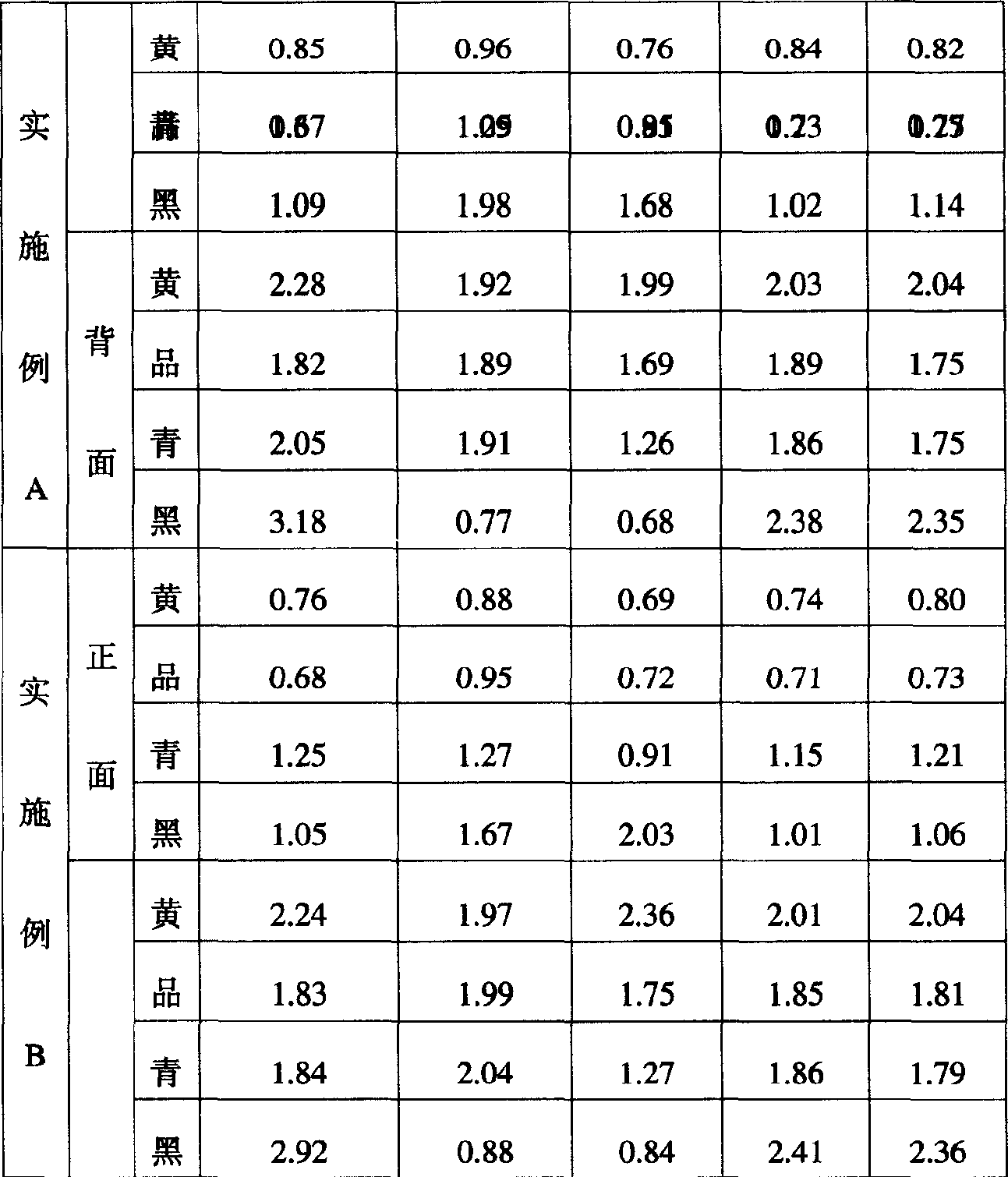

Embodiment 1

[0021] The ink-jet receiving material in the present invention comprises upper and lower ink-jet receiving systems, the upper layer is a permeable covering layer containing fillers and water-soluble resins, and the lower layer is a dye-accepting layer containing hydrophilic resins and cationic resins. The weight value of each component in the two layers can be set according to specific needs. The hydrophilic resin is one or more of gelatin, vinyl alcohol polymers, and cellulose derivatives. The cationic resin is used as an ink-fixing agent. The cationic resin used as ink fixing agent is at least one acrylic monomer or oligomer or polymer selected from polyvinylpyrrolidone, primary to tertiary amine or quaternary ammonium salt, allylamine, diallylamine and chlorinated diene Polymers and copolymers of amine monomers of propyldimethylamine. The weight ratio of hydrophilic resin and ink fixing agent in the dye receiving layer is 20:1. The transparent base is a polyester base. ...

Embodiment 2

[0041] The ink-jet receiving material in the present invention comprises upper and lower ink-jet receiving systems, the upper layer is a permeable covering layer containing fillers and water-soluble resins, and the lower layer is a dye-accepting layer containing hydrophilic resins and cationic resins. The quantity of each component in the two layers can be set according to specific needs. The hydrophilic resin is one or more of gelatin, vinyl alcohol polymers, and cellulose derivatives. The cationic resin is used as an ink-fixing agent. The cationic resin used as ink fixing agent is at least one acrylic monomer or oligomer or polymer selected from polyvinylpyrrolidone, primary to tertiary amine or quaternary ammonium salt, allylamine, diallylamine and chlorinated diene Polymers and copolymers of amine monomers of propyldimethylamine. The weight ratio of the hydrophilic resin and the ink fixing agent in the dye receiving layer is 10:1. The transparent base is a polyester bas...

Embodiment 3

[0059] The ink-jet receiving material in the present invention comprises upper and lower ink-jet receiving systems, the upper layer is a permeable covering layer containing fillers and water-soluble resins, and the lower layer is a dye-accepting layer containing hydrophilic resins and cationic resins. The quantity of each component in the two layers can be set according to specific needs. The hydrophilic resin is one or more of gelatin, vinyl alcohol polymers, and cellulose derivatives. The cationic resin is used as an ink-fixing agent. The cationic resin used as ink fixing agent is at least one acrylic monomer or oligomer or polymer selected from polyvinylpyrrolidone, primary to tertiary amine or quaternary ammonium salt, allylamine, diallylamine and chlorinated diene Polymers and copolymers of amine monomers of propyldimethylamine. The weight ratio of the hydrophilic resin and the ink fixing agent in the dye receiving layer is 1:5. The transparent base is a polyester base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com