Method for making bio-chip

A technology of biochips and production methods, applied in the directions of biochemical equipment and methods, measurement/inspection of microorganisms, biological testing, etc., can solve the problems of difficulty in realizing accurate quantification, etc., and achieve easy industrial production, uniform shape and size, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

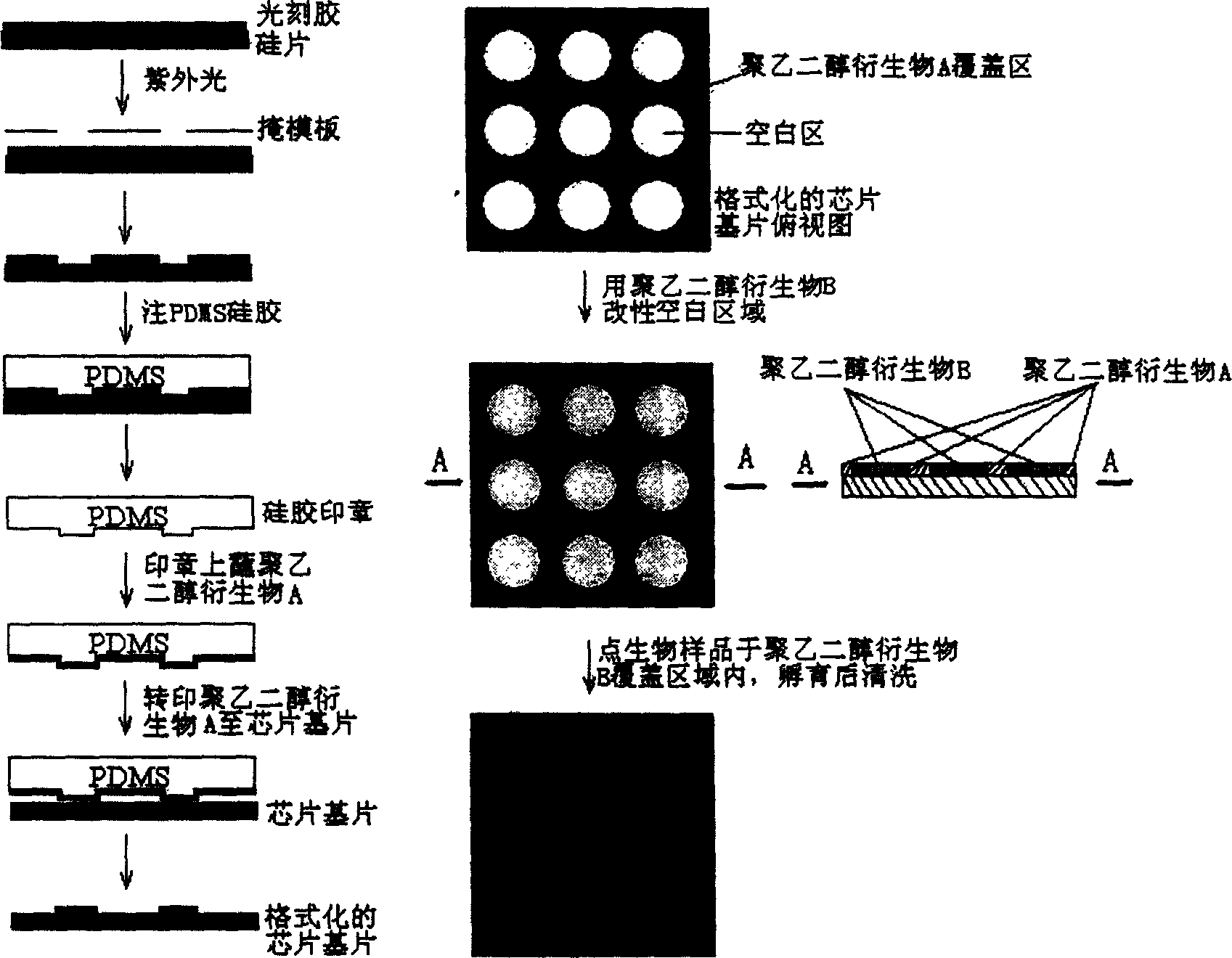

[0020] refer to figure 1 , a method for preparing a methyl polyethylene glycol derivative biochip with a silicon wafer as a substrate in detail

[0021] 1. First make the silicone stamp: apply the photoresist on the silicon wafer, and make a mold with 500 circular patterns through conventional photolithography technology;

[0022] 2. Pour commercially available PDMS silica gel onto the mold made in step 1, and after the PDMS silica gel is solidified, remove it from the mold to obtain a silica gel stamp with a circular pattern and a diameter of 20 microns;

[0023] 3. Put the polyethylene glycol derivative Cl on the silicone stamp made in step 2 3 Si(CH 2 ) 11 (OCH 2 CH 2 ) 3 OCH 3 The solution is coated on the silicone stamp made in step 2, and transferred on the silicon wafer;

[0024] 4. Soak the silicone stamp made in step 3 in polyethylene glycol derivative Cl 3 Si(CH 2 ) 11 (OCH 2 CH 2 ) 3 OCH 2 COOCH 2 CH 3 Medium modification without polyethylene glyc...

Embodiment 2

[0026] refer to figure 1 , a method for preparing a hydroxypolyethylene glycol derivative biochip with a gold-plated silicon wafer as a substrate in detail

[0027] 1. First make a silicone stamp: apply the photoresist on the silicon wafer, and make a pattern with 10,000 squares through conventional photolithography technology;

[0028] 2. Pour commercially available PDMS silica gel on the mold made in step 1, and after the PDMS silica gel solidifies, remove it from the mold to obtain a silica gel stamp with a square pattern and a side length of 100 microns;

[0029] 3. Place the polyethylene glycol derivative HS (CH) on the silicone stamp made in step 2 2 )11 (OCH 2 CH 2 ) 3 The OH solution is coated on the silicone stamp made in step 2, and transferred to the silicon wafer;

[0030] 4. Soak the silicone stamp made in step 3 in polyethylene glycol derivative HS (CH 2 ) 11 (OCH 2 CH 2 ) 7 OCH 2 Modified non-polyethylene glycol derivatives HS(CH 2 ) 11 (OCH 2 CH ...

Embodiment 3

[0032] refer to figure 1 , a method for preparing a methyl polyethylene glycol derivative biochip with a glass sheet as a substrate in detail

[0033] 1. First make the silicone stamp: apply the photoresist on the silicon wafer, and make a mold with 1500 circular patterns through conventional photolithography technology;

[0034] 2. Pour commercially available PDMS silica gel on the mold made in step 1, and after the PDMS silica gel is solidified, remove it from the mold to obtain a silica gel stamp with a circular pattern and a diameter of 200 microns;

[0035] 3. Put the polyethylene glycol derivative (CH 3 CH 2 O) 3 Si(CH 2 ) 11 (OCH 2 CH 2 ) 3 OCH 3 The solution is coated on the silicone stamp made in step 2, and transferred on the silicon wafer;

[0036] 4. Soak the silicone stamp made in step 3 in polyethylene glycol derivatives (CH 3 CH 2 O) 3 Si(CH 2 ) 11 (OCH 2 CH 2 ) 3 Modified non-polyethylene glycol derivatives in OCHO (CH 3 CH 2 O) 3 Si(CH 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com