Digital controlled high-pressure micronizer

A micro-powder milling and high-pressure technology, applied in grain processing, etc., can solve the problems of difficult adjustment of grinding roller pressure, unqualified powder forming rate, easy wear of contact surface, etc., and achieves the effects of saving manpower, reducing working noise, and being easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

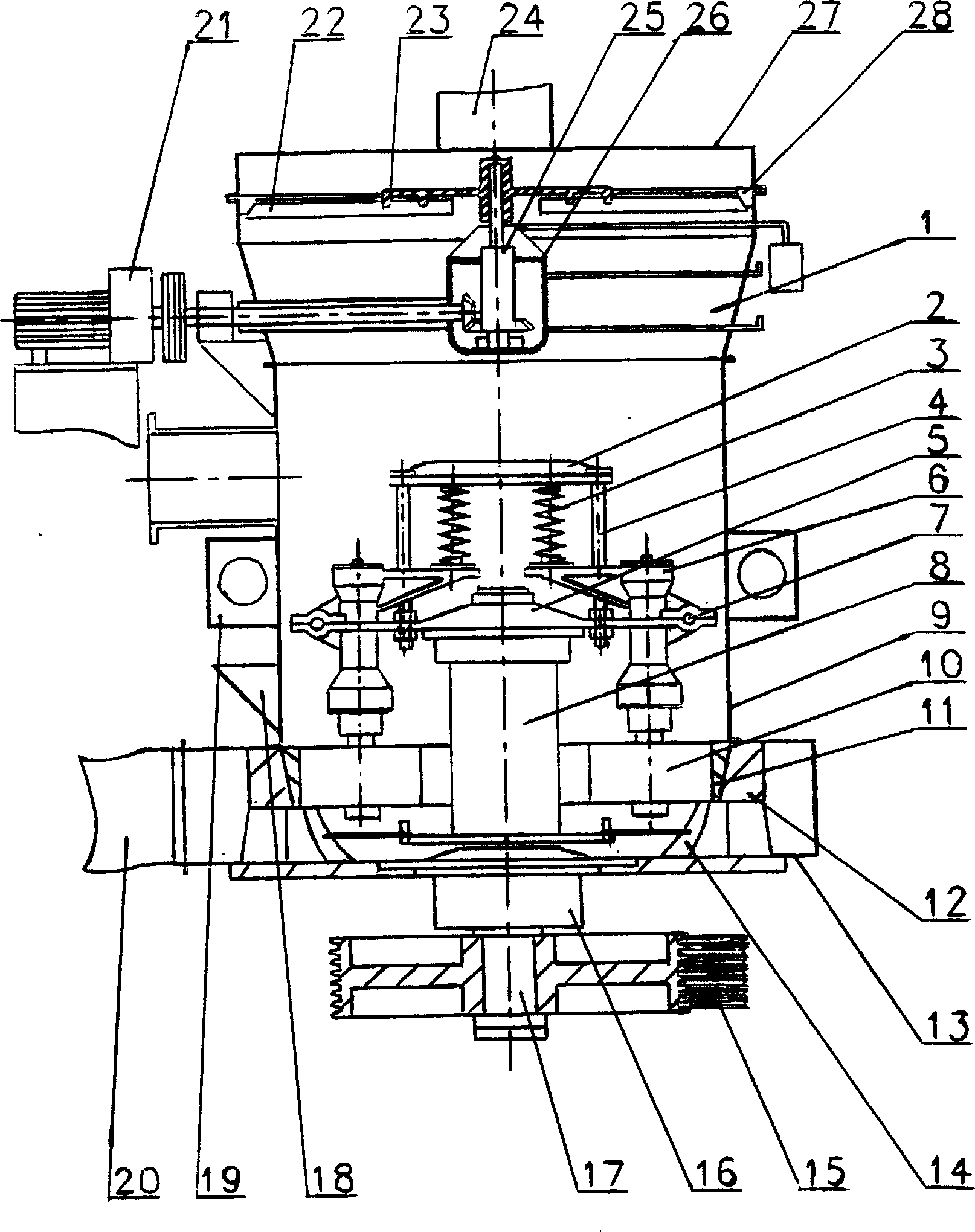

[0036] Combine below figure 1 , figure 2 The present invention is described in further detail:

[0037] Cover cylinder 9, grinding ring 11, air inlet volute 13, bearing seat 16 and feeding hopper 18 are respectively installed on the base 12 of CNC high-pressure micropowder mill, blade 14 is installed on blade frame 8, blade frame 8 It is connected with the grinding roller hanger 5 and is set on the main shaft 17 together. The grinding roller parts 6 are suspended on the grinding roller hanger 5 through the cross arm shaft 7, wherein each grinding roller part 6 is equipped with a spring 3, and the spring 3 is equipped with a spring pressure plate 2, and the spring pressure plate 2 is connected with the roller hanger 5 through the screw rod 4. The spring pressure plate 2 and the roller hanger 5 are connected and fixed through the screw rod 4 with nuts; in the middle of the cover tube 9, there is an air flow pressure reduction hole 19. A soft connection 20 is used between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com