Hartmann detection device for continuous sampling

A detection device and quality technology, applied in the field of continuous sampling Hartmann detection devices, can solve the problems of indirect detection results, inability to measure local errors, calculation errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

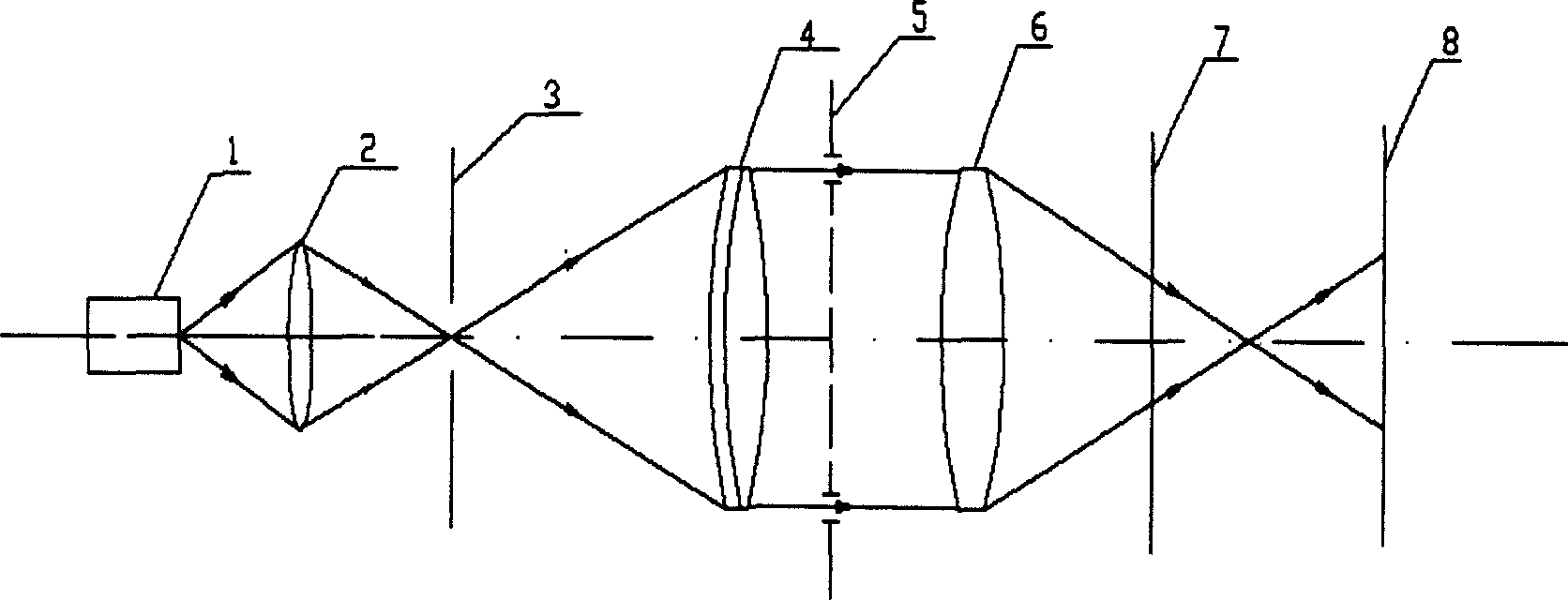

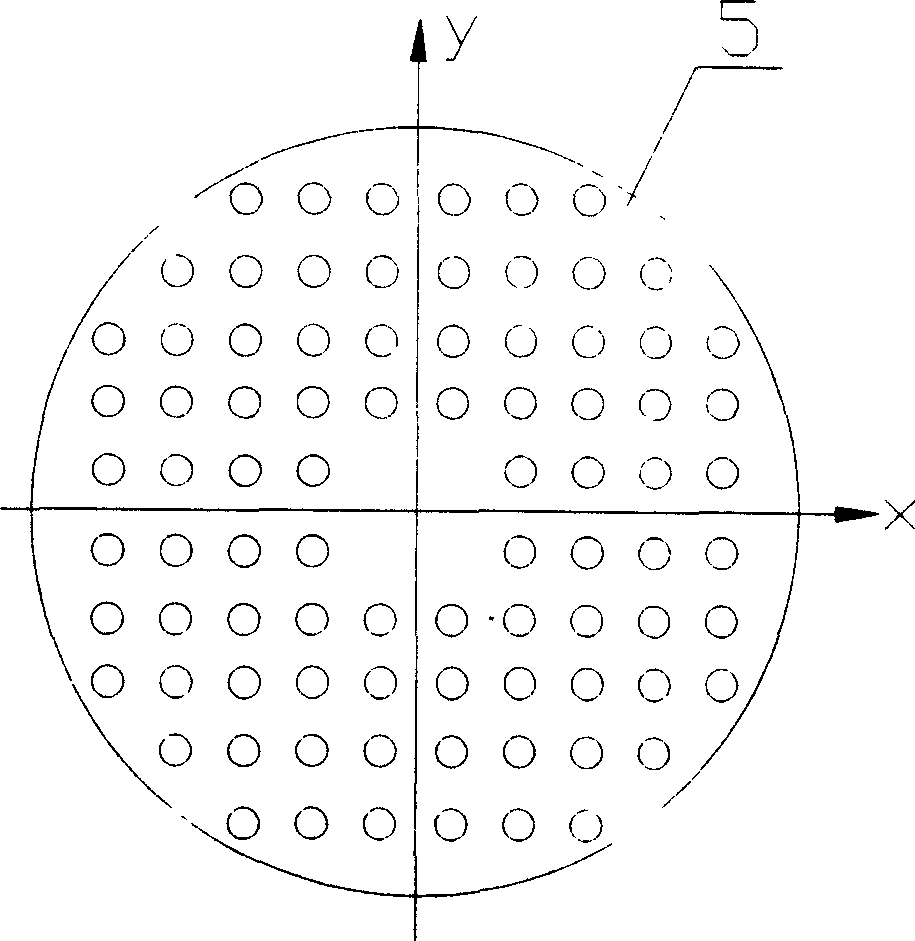

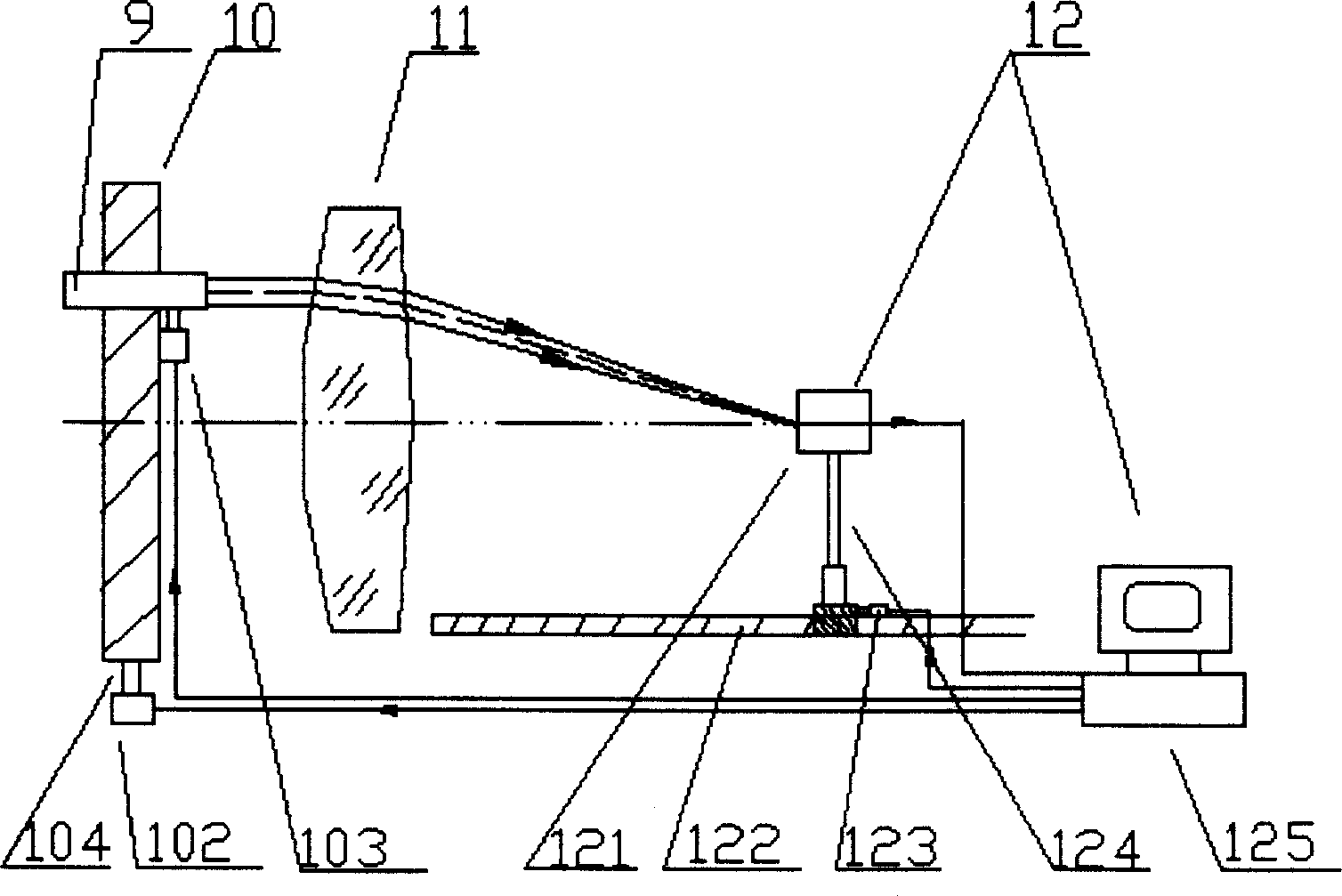

[0036] see first image 3 , image 3It is a structural schematic diagram of a specific embodiment of the continuous sampling Hartmann detection device of the present invention. As can be seen from the figure, the present invention is composed of an illumination system 9, a light beam scanning mechanism 10, an inspected lens 11, an image receiving system 12, and system control and data processing software. The illumination system 9 is fixed on the one-dimensional electric adjustment frame 103 in the beam scanning mechanism 10 , and the one-dimensional electric adjustment frame 103 is controlled by a computer 125 . The beam scanning mechanism 10 is installed on the bracket 104, and one side of the bracket 104 is fixed with a first stepping motor 102 controlled by a computer 125, and the beam scanning mechanism 10 can be driven by the first stepping motor 102 around the The optical axis of the lens 11 rotates; the inspected lens 11 has a converging effect on the light beam. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com