Hot press for membrane/sheet detection sample of thermoplastic macromolecule material

A technology of thermoplastic polymers and hot presses, applied in the direction of sampling devices, etc., to achieve the effects of prolonging the service life, being easy to move, and the overall structure is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

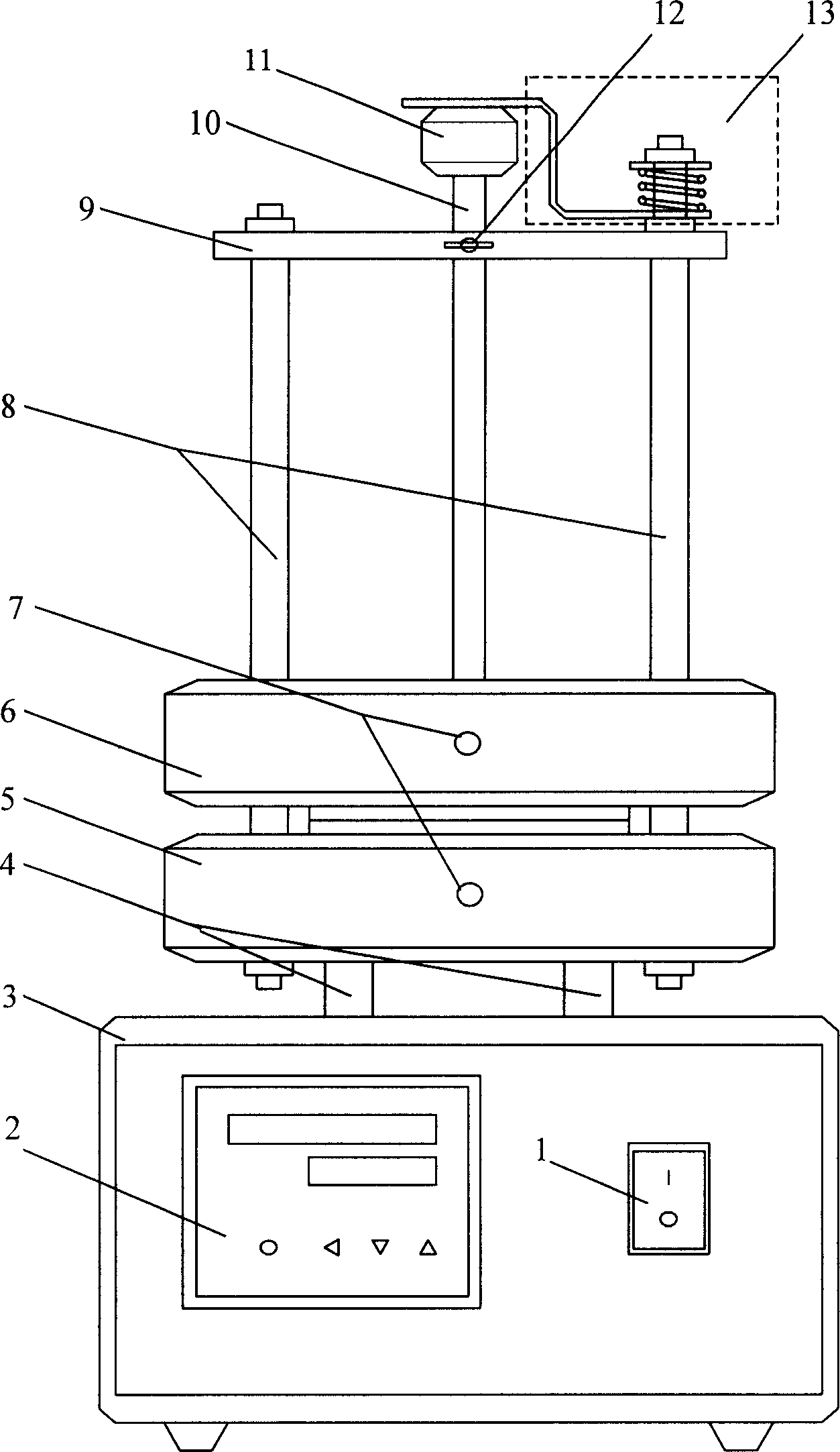

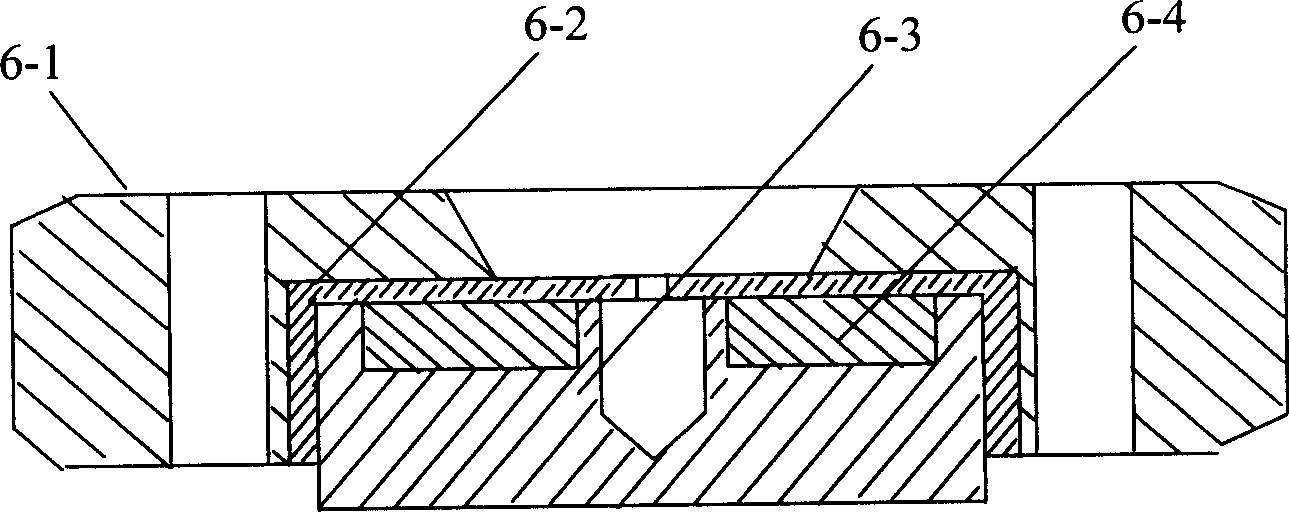

[0011] In the present invention, parts such as the instrument case, support column, guide column, crossbeam, lifting dowel, lifting cap, and locking nut are all made of stainless steel; the insulation sleeves of the upper and lower pressure plates are made of phenolic glass fiber reinforced plastic, and the diameter of the outer circle is 150mm, thickness 40mm; the sample boss is made of brass with good thermal conductivity, the outer diameter is 76mm, and the thickness is 18mm; the sample boss is placed in the groove at the center of the insulation cover, and the sample boss is embedded in the groove One side of the groove is embedded with an annular sheet heater with an outer diameter of 74mm, an inner diameter of 2mm, and a thickness of 2mm; 80mm heat insulation sleeve with a thickness of 20mm; each component of the upper and lower pressure plates is fixed with jackscrews. When using the device of the present invention to prepare thermoplastic polymer material hot-pressed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com