Dual resonance frequency driving method of magnetic mini travel robot

A dual-resonant frequency, driving method technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of inability to achieve two-way swimming, difficult robot control, leakage Safety and other issues, to achieve the effect of improving reliability and practicability, easy detection, and stable attitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

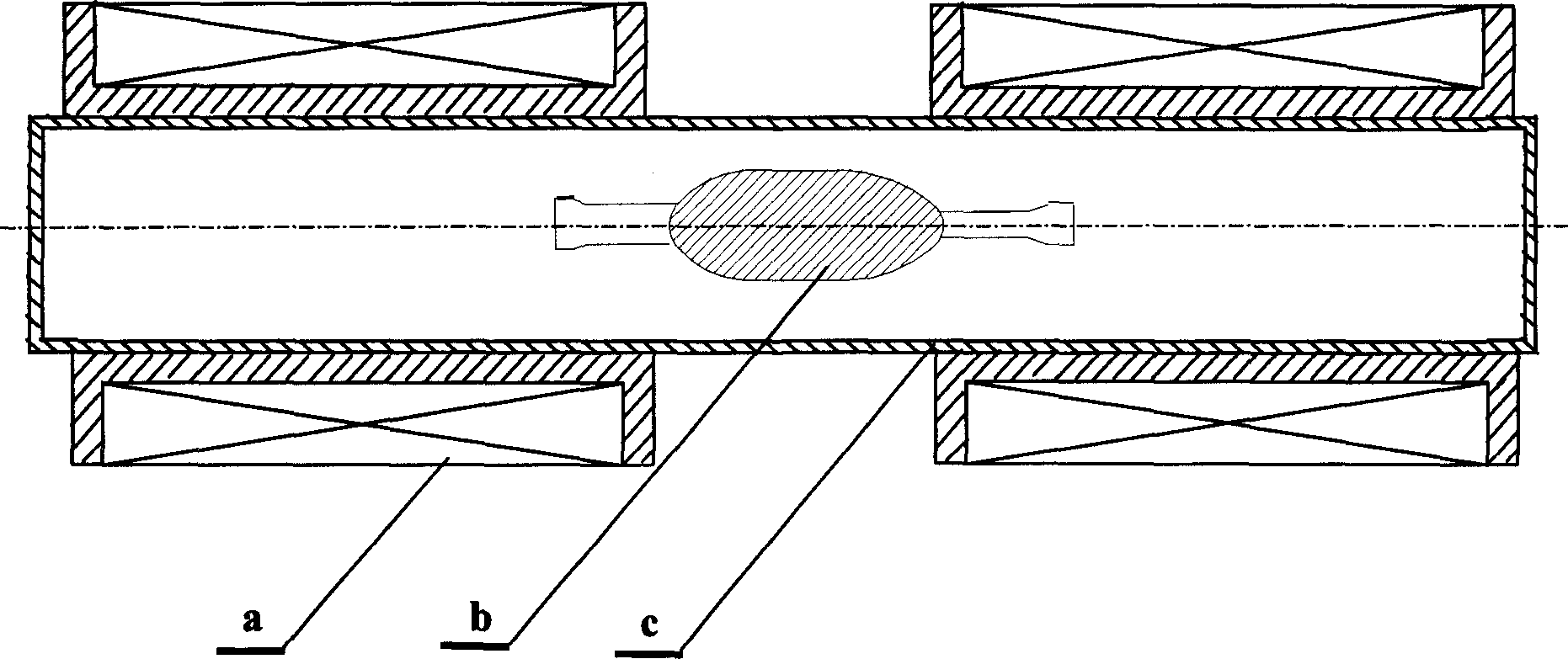

[0039] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

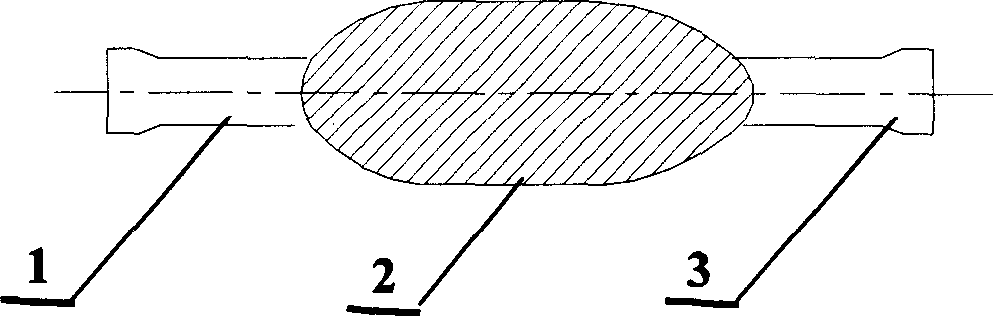

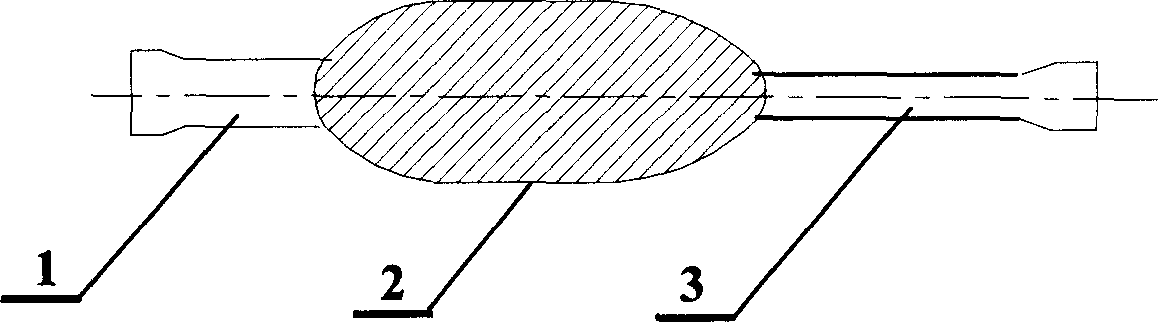

[0040] Structural representation of the above-mentioned embodiment scheme onefigure 2 In the process, the structural design of the front-end driver 1 and the back-end driver 3 must first be completed. The front and rear drivers are different kinds of substrates, and the two kinds of substrates are selected to have the same overall dimensions. The thickness of the magnetostrictive material film is adjusted so that the second-order resonant frequency of the film with a small elastic modulus of the substrate is the second-order resonant frequency of the film with a large elastic modulus of the substrate to satisfy the following relationship, the second-order resonant frequency of the front-end driver 1 The range of frequency is 10 to 30 Hz, the range of the second-order resonance frequency of the back-end driver 3 is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com