Nonlinear model predictive control method based on support vector machine for groove type reactor

A support vector machine and trough reactor technology, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as difficult acquisition of nonlinear models, poor generalization ability, and difficult determination of geometric topology , to achieve the effects of high nonlinear fitting accuracy, strong generalization ability, and simple identification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The details are described below according to each block diagram.

[0039] 1. Nonlinear prediction model based on support vector machine

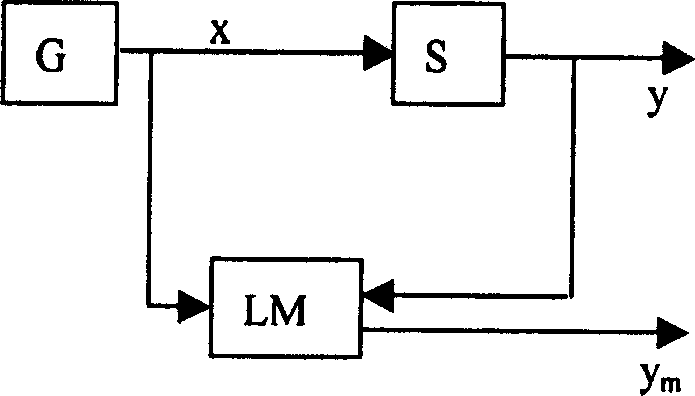

[0040] A support vector machine is a novel learning machine. image 3 A block diagram of the general model for learning is given. The generator (G) produces a random vector x∈R n , which are drawn independently from a fixed but unknown probability distribution function F(x). A trainer (S) that returns an output value y for each input vector x. A learning machine (LM), which is capable of implementing a certain set of functions f(x, a), a ∈ Λ, where Λ is a set of parameters. The learning problem is to select the function that best approximates the trainer response from a given set of functions f(x, a), a ∈ Λ such that y m able to approximate y.

[0041] Figure 4 A block diagram of support vector machine learning is given. The basic idea of the support vector machine is to map the linearly inseparable low-dimensional space da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com