Fluid driving bending joint of spiral spring frame

A technology of helical springs and bending joints, applied in the direction of claw arms, manipulators, manufacturing tools, etc., can solve the problems of energy consumption, high manufacturing cost, and complex structure, and achieve high dynamic control accuracy, easy axial deformation, and small fluid flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below the present invention will be further described in conjunction with the implementation of scheme I in the accompanying drawings:

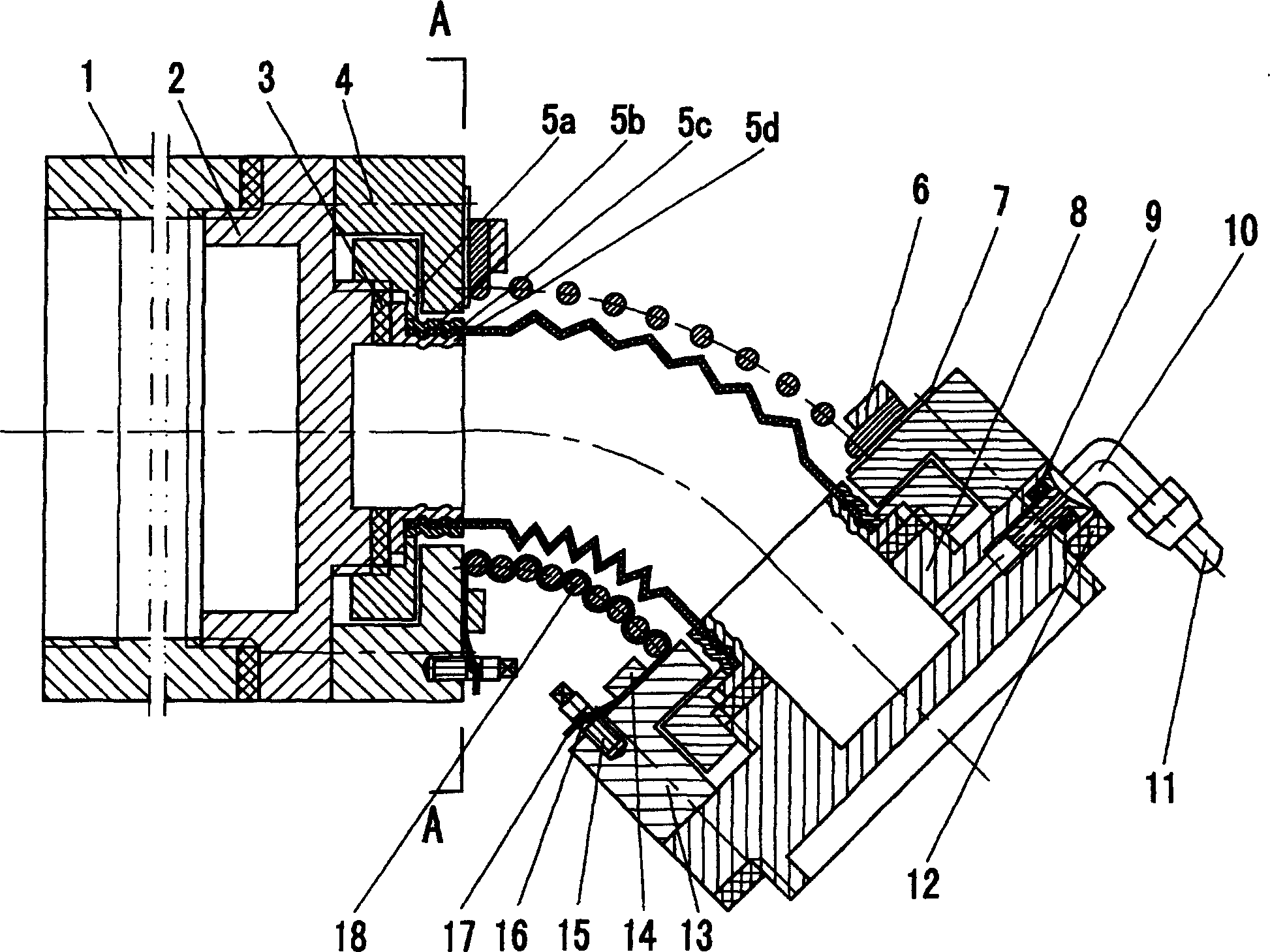

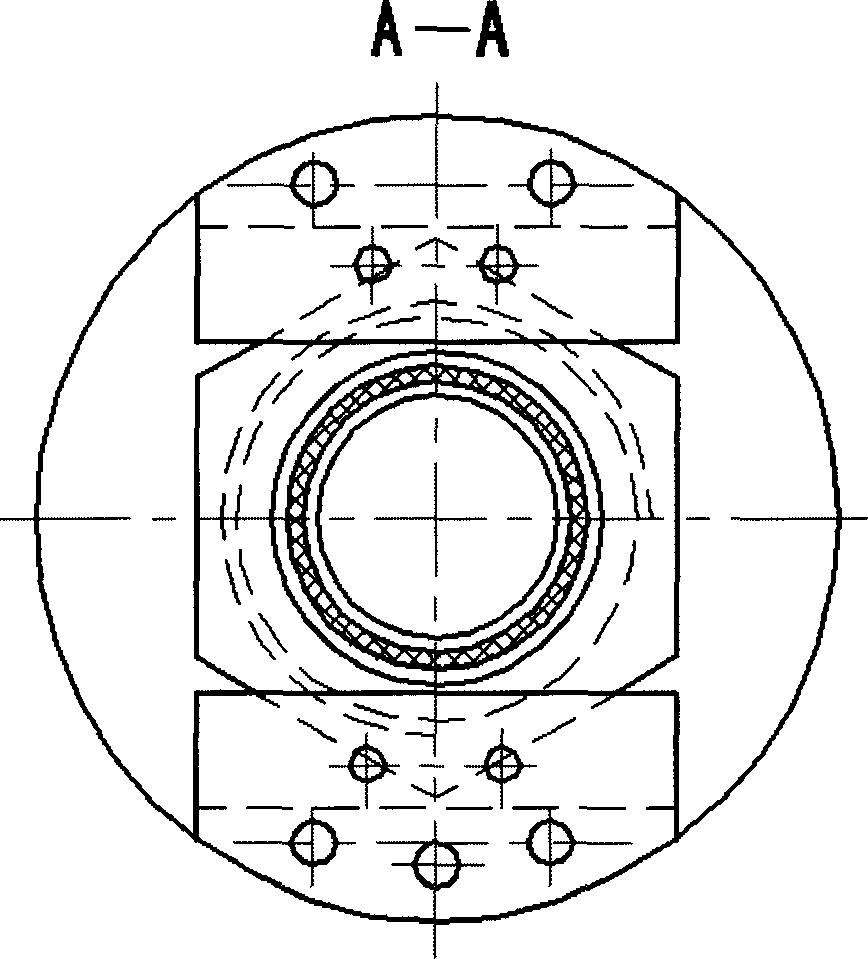

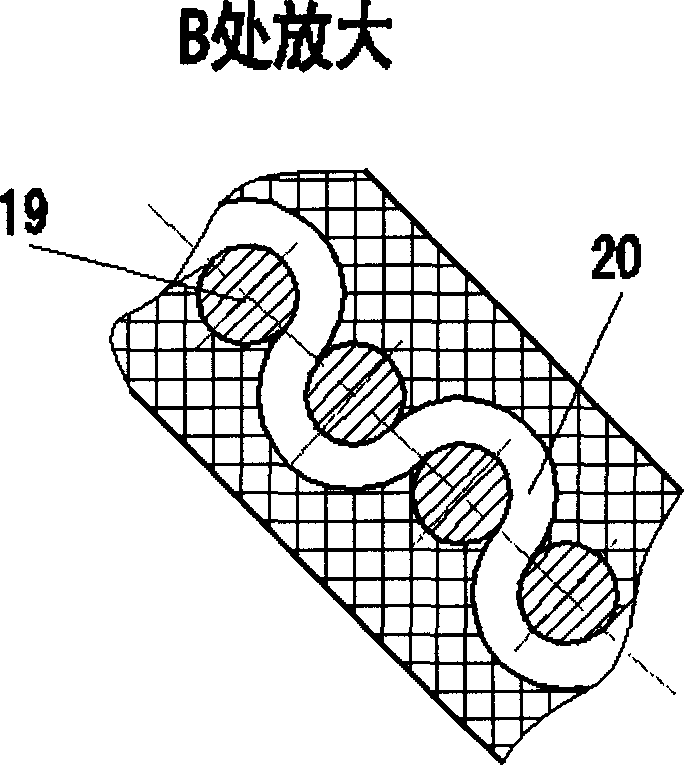

[0029] The joint of plan I is mainly composed of intermediate section 1, head seat 2, large sealing ring 3, spring fixing seat 4, connecting sealing nut 5a, fastening shell 5b, elastic wave shell 5c, flange inner sleeve 5d, spring fixing pressure plate 6, Adjusting gasket 7, tailstock 8, small sealing ring 9, right-angle pipe joint 10, hose 11, thickness adjusting ring 12, tensioning wire seat 13, wire guide frame 14, tensioning screw 15, fixing screw 16, fixing wire 17, helical spring 18, annular weft 19, winding warp 20 etc. constitute.

[0030] Its specific implementation method is:

[0031] (1) The longitudinal section shape of the single elastic wave shell of the elastic wave shell 5c is "V", "U" or "Ω". through

[0032] 20. In this way, the elastic wave shell 5b is not easily deformed in the radial direction, and its bearing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com