Fuel gasifier of diesel engine

A gasifier, diesel engine technology, applied in machine/engine, combustion air/combustion-air treatment, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

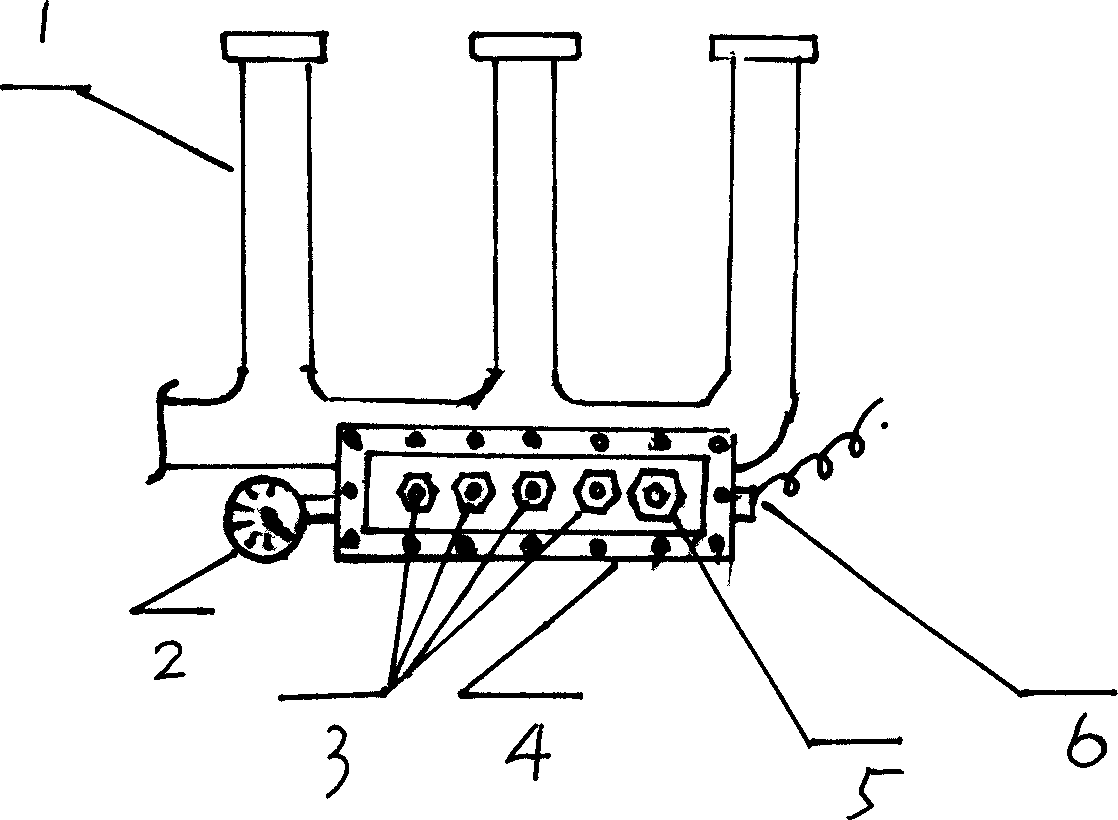

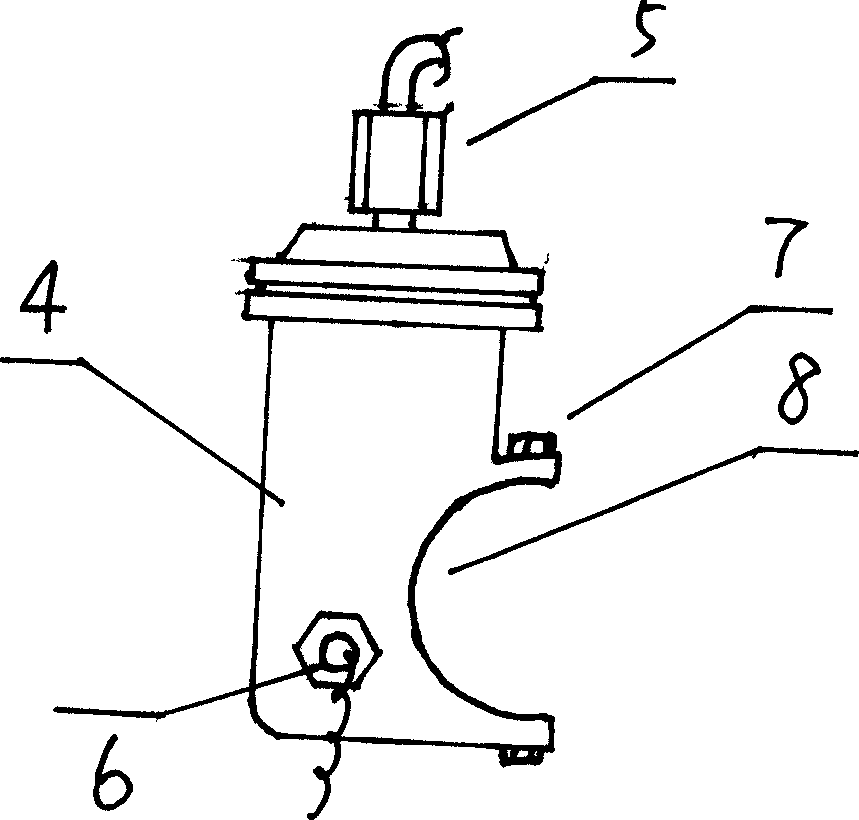

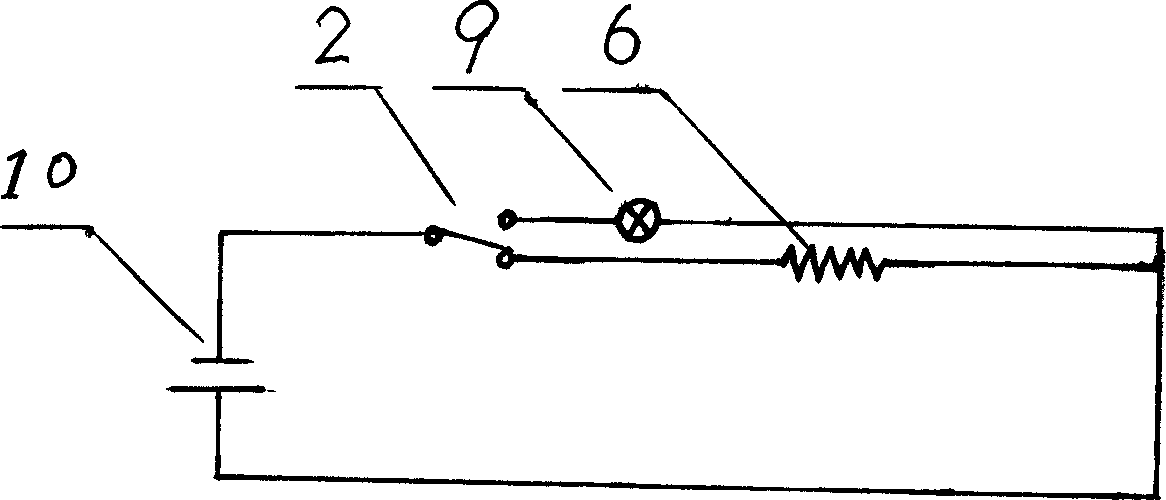

[0009] Before installing the fuel vaporizer on the exhaust pipe of the diesel engine, first tap a few screw holes on the exhaust pipe according to the fixed screw position and standard on the groove 8 of the fuel vaporizer 4 exhaust pipe, and then Fix the fuel vaporizer on the exhaust pipe, and connect the electric heater 6, the indicator light 9, the electric contact 2 of the temperature pressure gauge and the battery 10. The connection method is as follows: image 3 As shown, when the preparatory work is completed, the start-up work can be carried out.

[0010] After turning on the power supply of the diesel engine, stand still for a few minutes. At this time, it is the warm-up time for the fuel gasifier 4 of the diesel engine. , the electric heating rod is heated to vaporize the fuel oil. When the temperature in the fuel vaporizer 4 reaches the boiling point of diesel oil, a large amount of diesel oil evaporates and gasifies into diesel steam. At this time, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com