Plate heater, fixer and image forming device

A heater and plate-shaped technology, applied in the direction of electric heating device, heating element shape, electric heating plate heating arrangement, etc., to achieve the effect of preventing cracks and cracks, excellent weather resistance, and suppressing fluctuations and changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

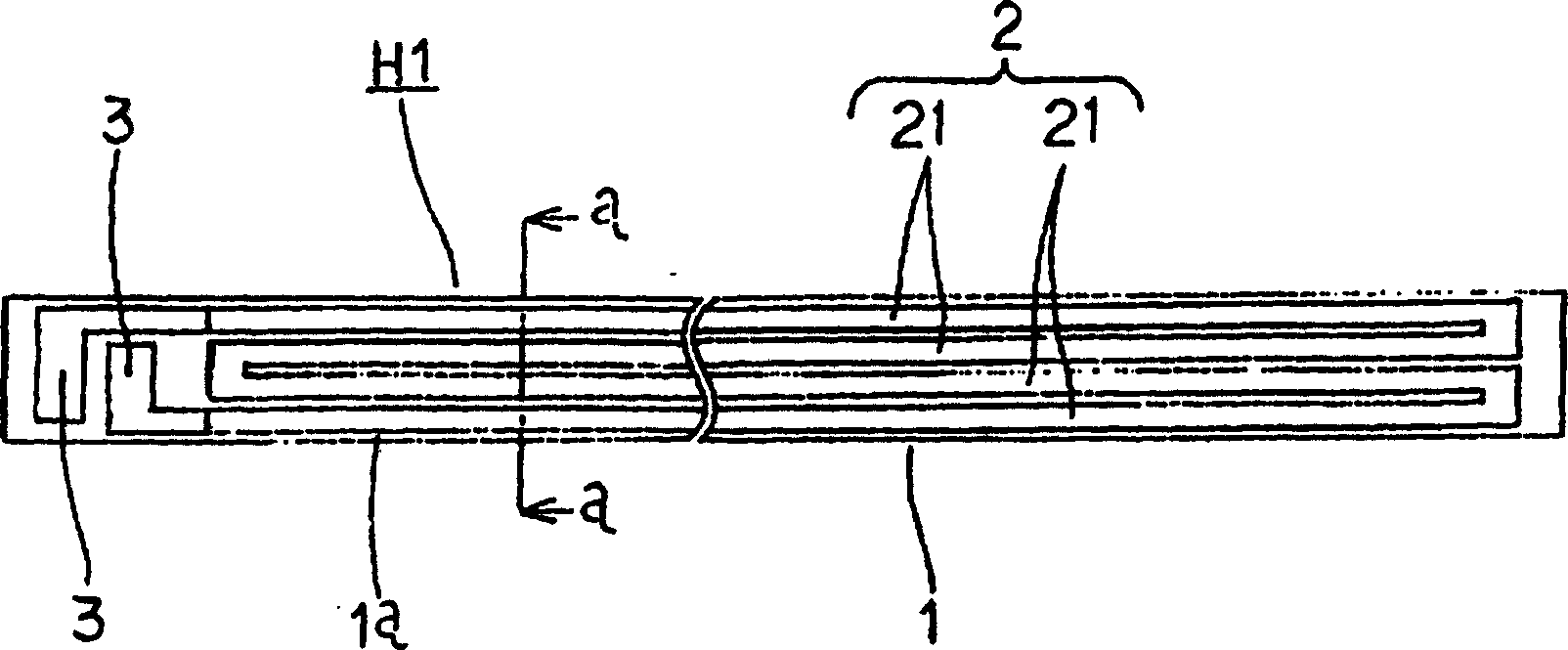

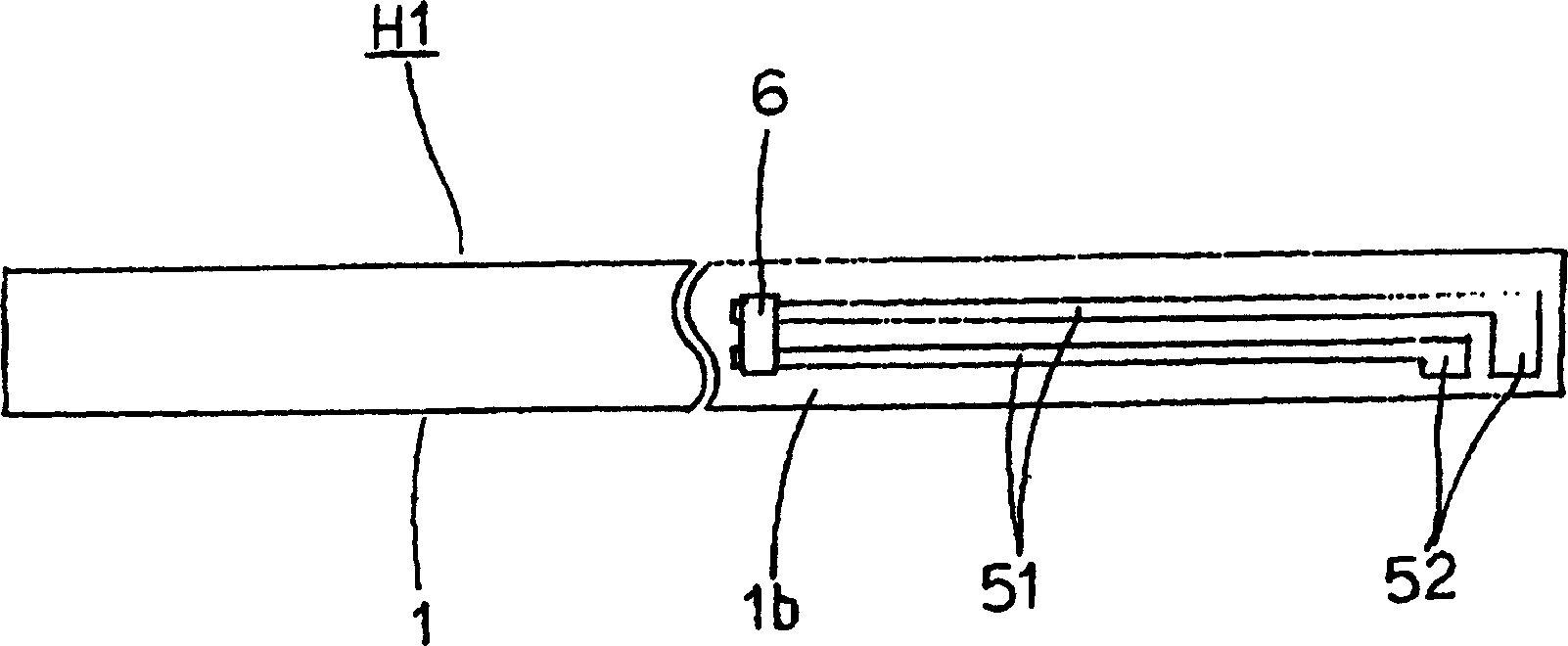

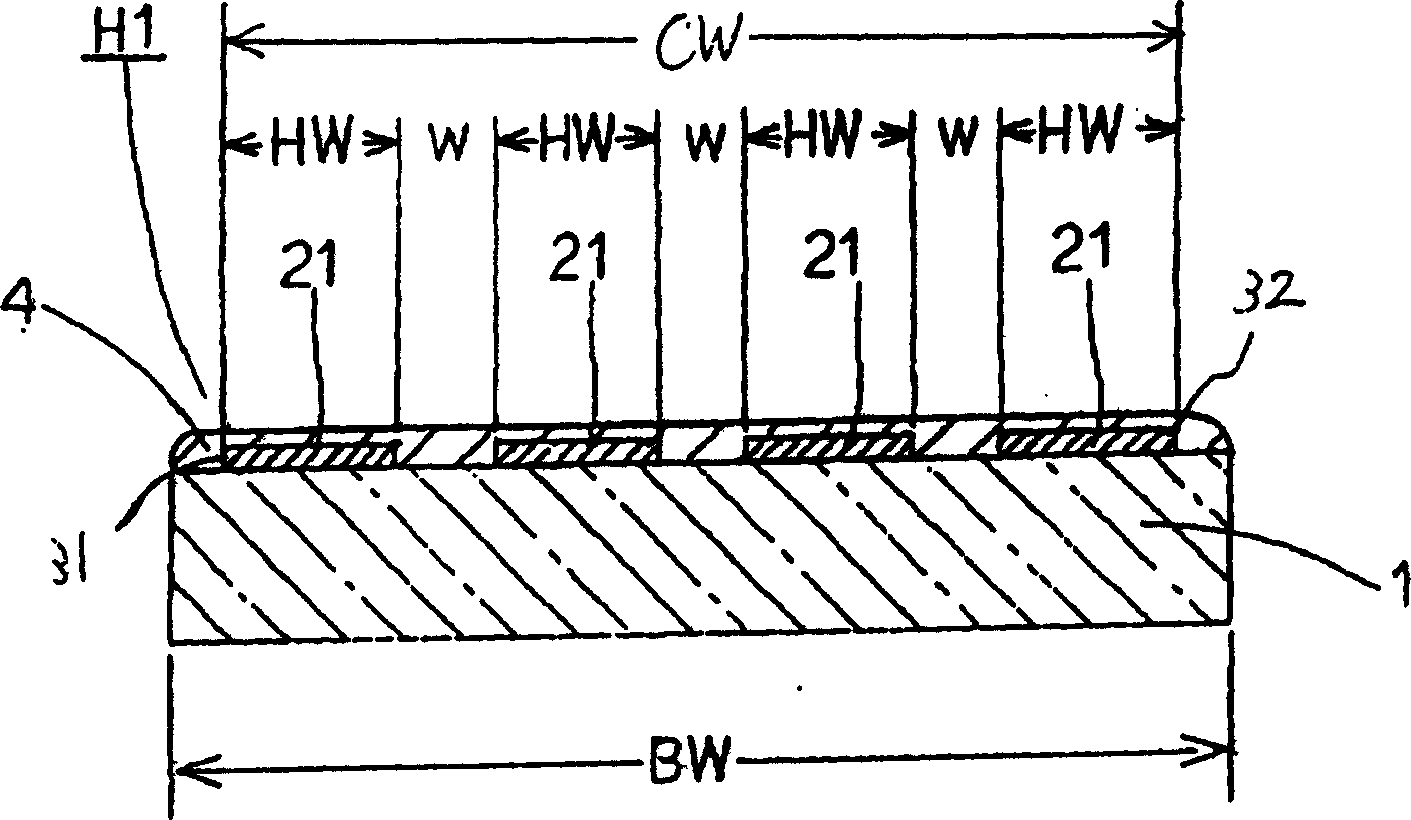

[0074] Hereinafter, embodiments of the plate heater according to the present invention will be described with reference to the drawings. figure 1 It is the front view of the plate heater H1 after cutting out the middle part, figure 2 for figure 1 Rear view of the plate heater H1, image 3 for along figure 1 The enlarged vertical cross-sectional view of the part cut along the line a-a in the arrow (Note: The thickness and width of each layer of the resistance heating element, the terminal part for power feeding, the wiring conductor and the covering layer shown in each figure are relative to the substrate. Exaggerated, but the size is not enlarged in proportion. In addition, the front side surface and the back side surface of the substrate are defined in the description of the drawings, and sometimes they are reversed in practice.)

[0075] 1 in the figure is a large-scale substrate with a length of about 300nm, a width of about 6.1mm, and a thickness of about 0.7mm, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com