Preparation method of carbon

A carbon material and carbonization technology, applied in special forms of dry distillation, solid fuels, biofuels, etc., can solve the problems of short combustion time, incomplete carbonization, and low calorific value, and achieve long combustion time, high product density, and calorific value. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples illustrate the preparation method of the present invention.

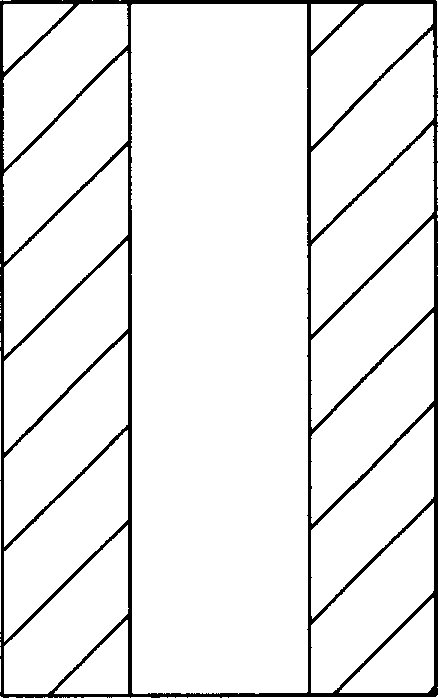

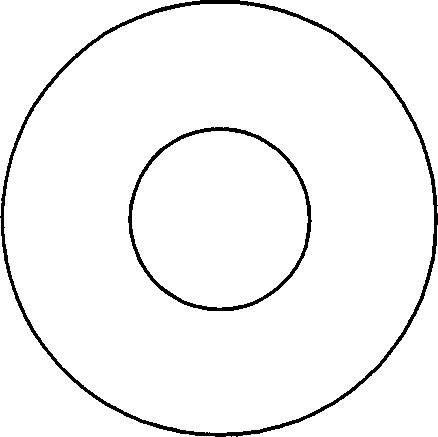

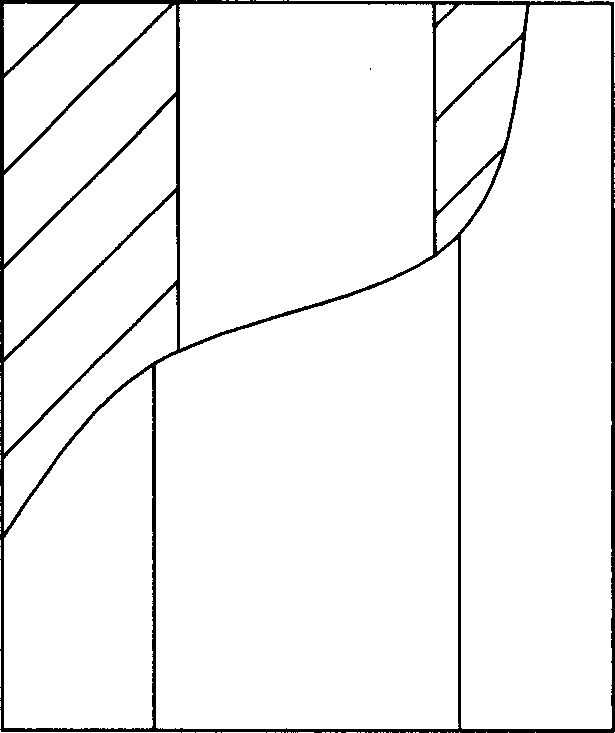

[0016] First crush organic matter such as rice husk, wood, branches, rice straw, wheat straw, leaves, etc. (smaller organic matter such as rice husk does not need to be crushed), then carbonize it into carbon material in a carbonization furnace, and then use a crusher to remove the carbon. The material is crushed, and then mixed with binder (starch or clay) and water in different proportions in Table 1, and then made into products of different shapes and specifications in Table 1 in the forming equipment, and dried in the drying room. . The combustion status of the finished product is shown in Table 1.

[0017]

[0018] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com