Inhibiting calcium carbonate additive

A calcium carbonate, inhibitory technology, used in fibrous fillers, inorganic pigment processing, chemical instruments and methods, etc., can solve the problems of materials that cannot be purchased through commercial channels, not described, and achieve good biocompatibility and acidity. Stability, improved mechanical properties, effect of low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0350] At an initial temperature of 10°C, will contain 20% CO 2 and 80%N 2 CO 2 The gas mixture was introduced into 4 liters of a calcium hydroxide suspension having a CaO concentration of 75 g / l. The gas flow rate is 300 l / h. The reaction mixture was stirred at 350 rpm and the heat of reaction was removed during the reaction. When the conductivity drops suddenly (the drop exceeds 0.5mS / cm / min, and the conductivity drops by more than 0.25mS / cm within 30 seconds), add 0.7% amino trisulfite in terms of CaO (as a theoretical reference value) to the suspension. (methylene phosphonic acid). When the reaction mixture is quantitatively carbonated into spherical calcium carbonate particles, the reaction to produce spherical calcium carbonate particles is completed, wherein the pH of the reaction mixture is 7 to 9. In this case, the reaction was complete after about 2 hours, and the pH of the reaction mixture was 7 at the end of the reaction.

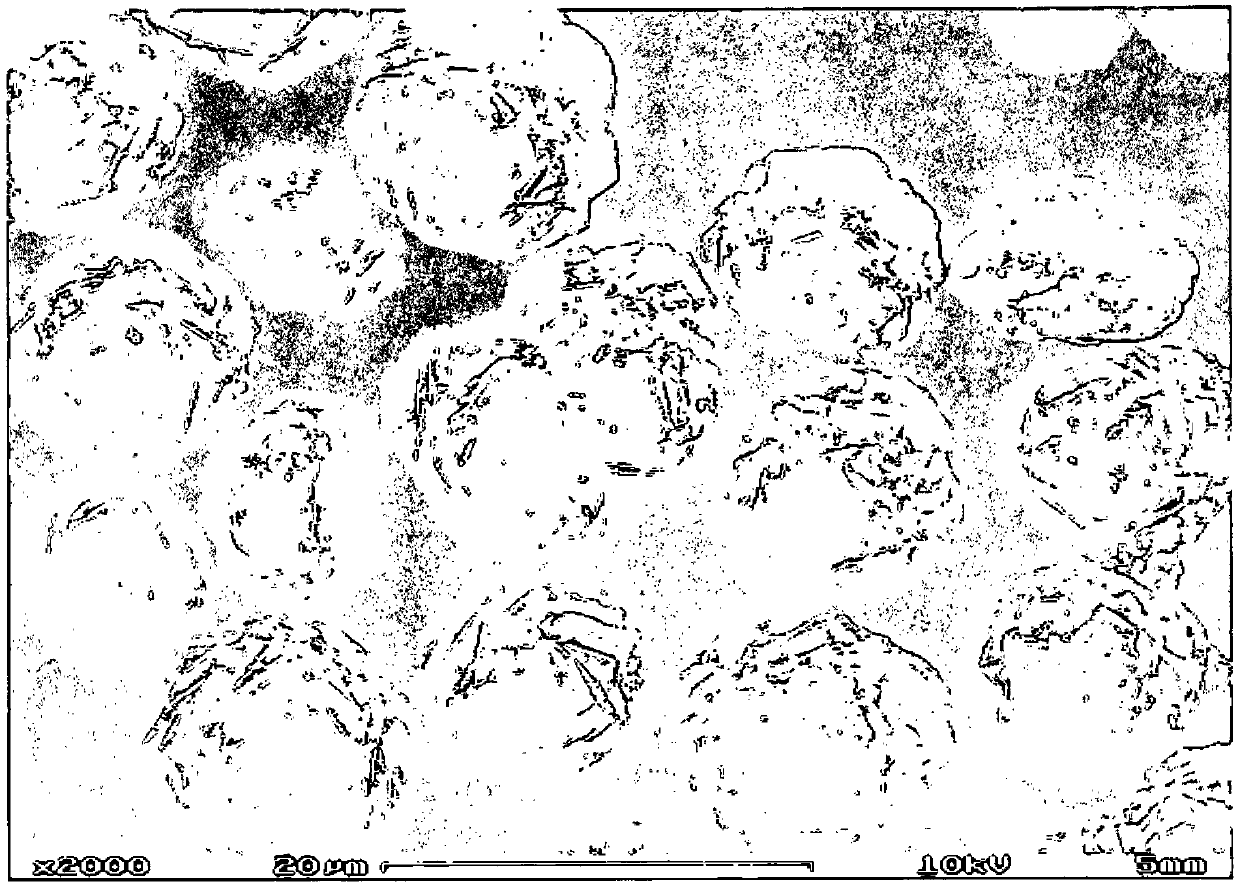

[0351] The resulting spherical calc...

example 2

[0352] Example 2 (Inhibitory Calcium Carbonate Microparticles; Reactant of Compositions According to the Invention)

[0353] Put 500ml of deionized water in a 1000ml beaker. 125 g of spherical calcium carbonate particles according to Example 1 were added with stirring, and the resulting mixture was stirred for 5 minutes. Slowly add 37.5g of 10% sodium metaphosphate (NaPO 3 ) n solution, and the resulting mixture was stirred for 10 minutes. 75.0 g of 10% phosphoric acid was slowly added, and the resulting mixture was stirred for 20 hours. The precipitate was separated and dried overnight in a drying oven at 130°C. The average particle diameter of the obtained spherical calcium carbonate fine particles was also 12 μm.

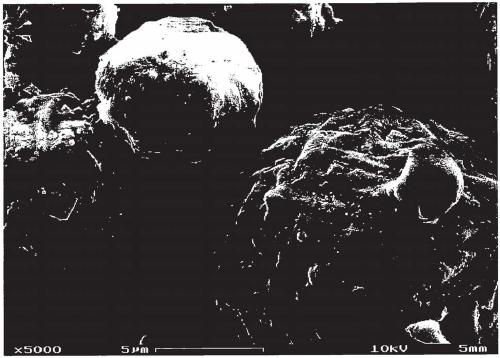

[0354] The REM photograph of spherical calcium carbonate particles is as figure 2 shown. A thin layer of phosphate can be seen on the surface of the spherical calcium carbonate particles.

example 3

[0356] Referring to the method described in JP62083029A, a composite powder consisting of spherical calcium carbonate microparticles and polylactide (PLLA) was prepared using an apparatus NHS-1. Cool with 12°C cold water. Polylactide particles 1 were used as master batches, and the spherical calcium carbonate particles in Example 1 were used as sub-particles (fillers).

[0357] Mix 39.5 g of polylactide particles with 26.3 g of CaCO 3 The powder is mixed and filled at 6400 rpm. The rotor speed of the unit was set to 6400 revolutions per minute (80 m / s) and the dosed material was processed for 10 minutes. The maximum temperature reached in the NHS-1 grinding chamber was 35°C. A total of 7 replicates were performed using the same amount of material and machine settings. A total of 449 g of composite powder was recovered. Composite powder collected by manual dry sieving through a 250 μm sieve. The sieve residue (fraction >250 μm) was 0.4%.

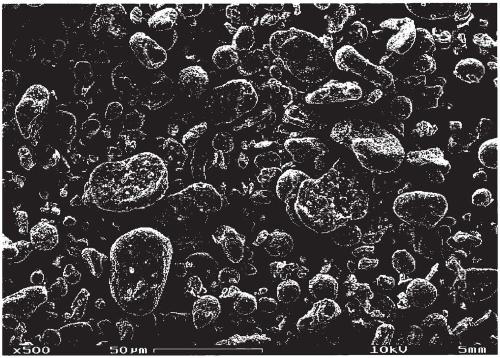

[0358] The REM photo of the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com