Desalinization method by stepwise circulation of non-explosive evaporation and condensation

A boiling evaporation and desalination technology, applied in heating water/sewage treatment, etc., can solve the problems of complex process, huge investment and huge system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

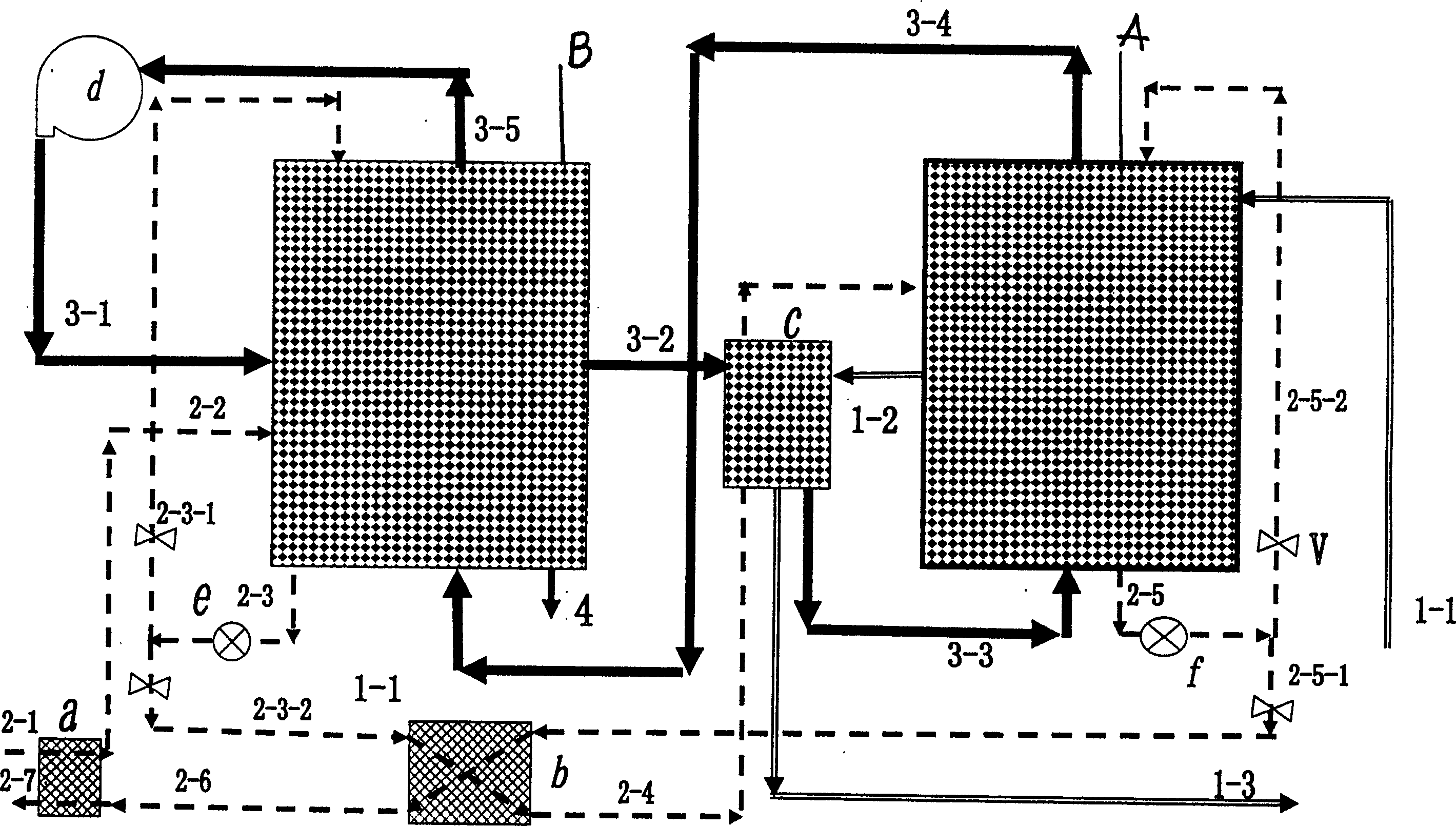

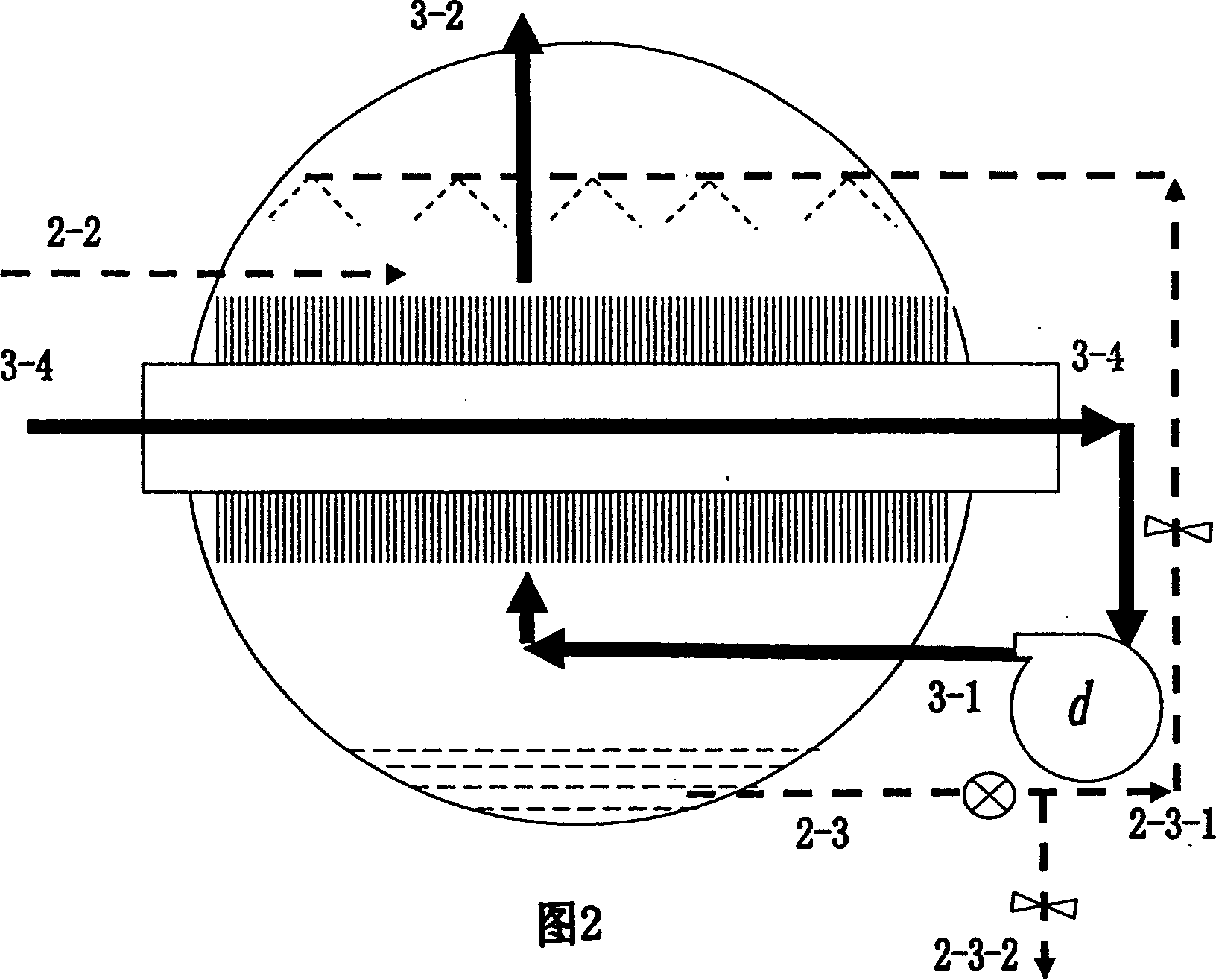

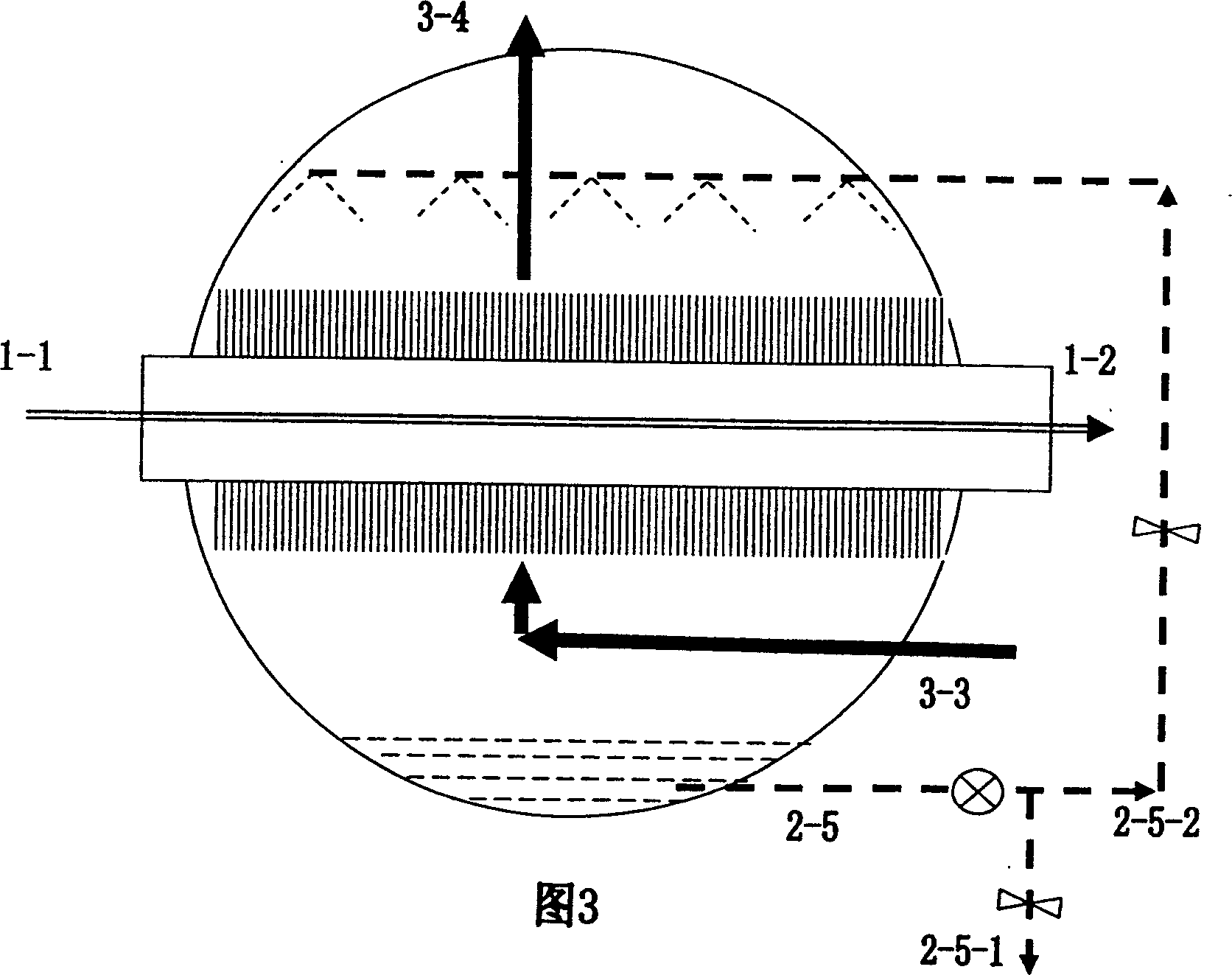

[0010] The invention is that the hot fluid enters the heating evaporator, passes through the heat exchanger, releases heat, and simultaneously heats the spray salt water on the other side and the humid air flowing in the opposite direction with the spray water, and part of the water evaporates after being heated and is heated up. The hot air is taken away to realize the separation of water and salt; the high-temperature, high-humidity saturated air sent by the heating evaporator enters the evaporation and condenser. A condensation channel and an evaporation channel are arranged therein, and the two are separated by a partition wall. The high-temperature saturated air entering the condensation channel is cooled by the low-temperature salt water sprayed in the evaporation channel on the other side of the channel and the counter-flowing humid air, loses condensed water, releases condensation heat, and the saturated air returns to work after the temperature has dropped. A closed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com