Radial tyre vulcanization production line

A radial tire and production line technology, applied in the field of large-scale production lines, can solve the problems of unfavorable radial tire production and promotion, difficulty in forming large-scale production lines, high operating costs of vulcanizers, etc., to improve the return on investment, simple and reliable design, and simple structure. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

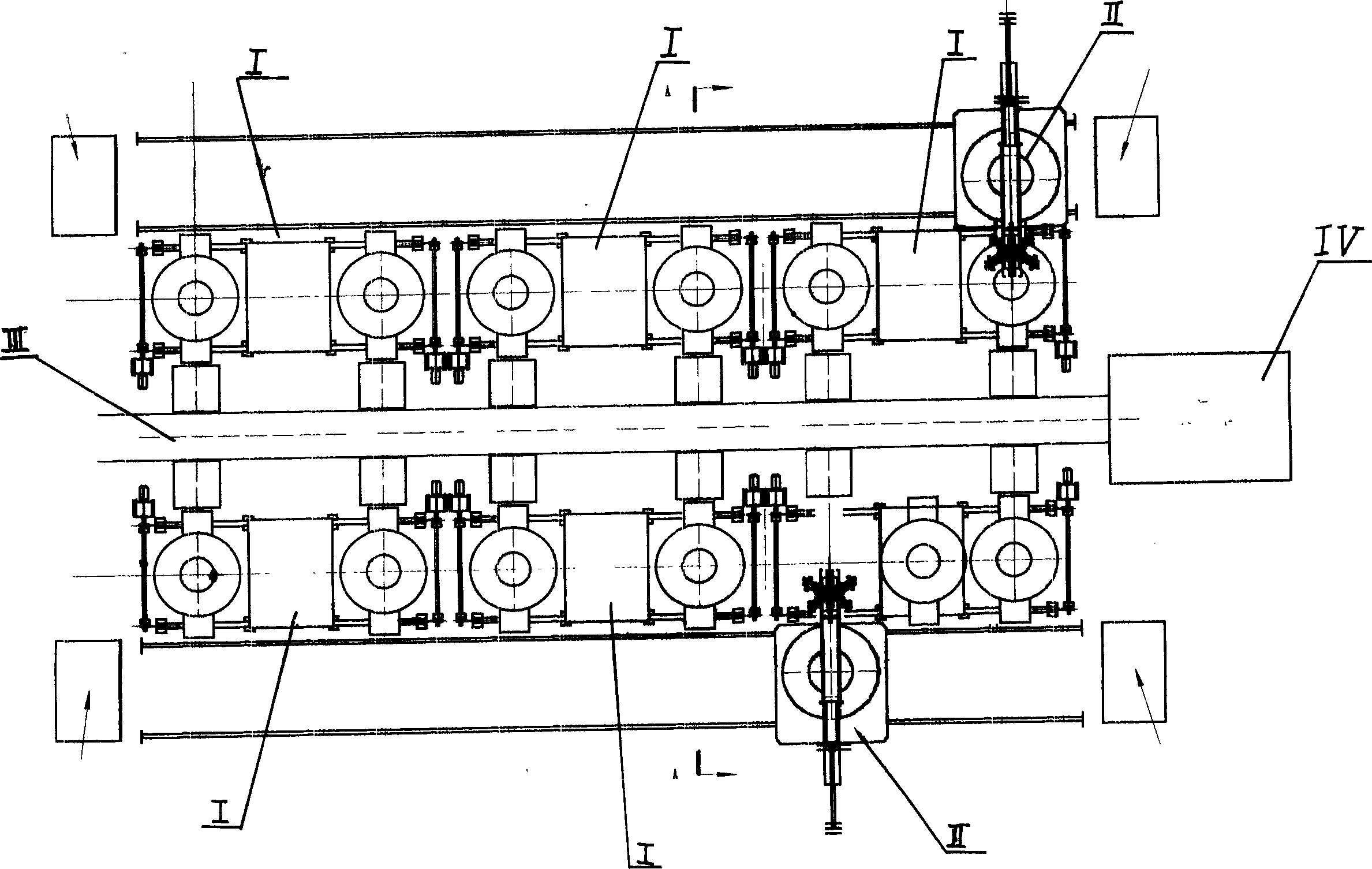

[0027] Such as figure 1 A radial tire vulcanization production line is shown, in which multiple sets of radial tire vulcanizers I are connected end to end, and the finished product conveyor line III is arranged on the side; each group of radial tire vulcanizers I is equipped with a special mobile manipulator II for radial tire vulcanizers; each radial tire vulcanizer is Machine I shares a hydraulic station IV. This embodiment configures 6 radial tire vulcanizers 1 and divides them into two groups, each group of 3 radial tire vulcanizers 1 is arranged in a straight line, two groups of radial tire vulcanizers 1 are placed in parallel, the middle of these two groups of radial tire vulcanizers 1 Set the shared finished product conveying line III and the shared hydraulic station IV.

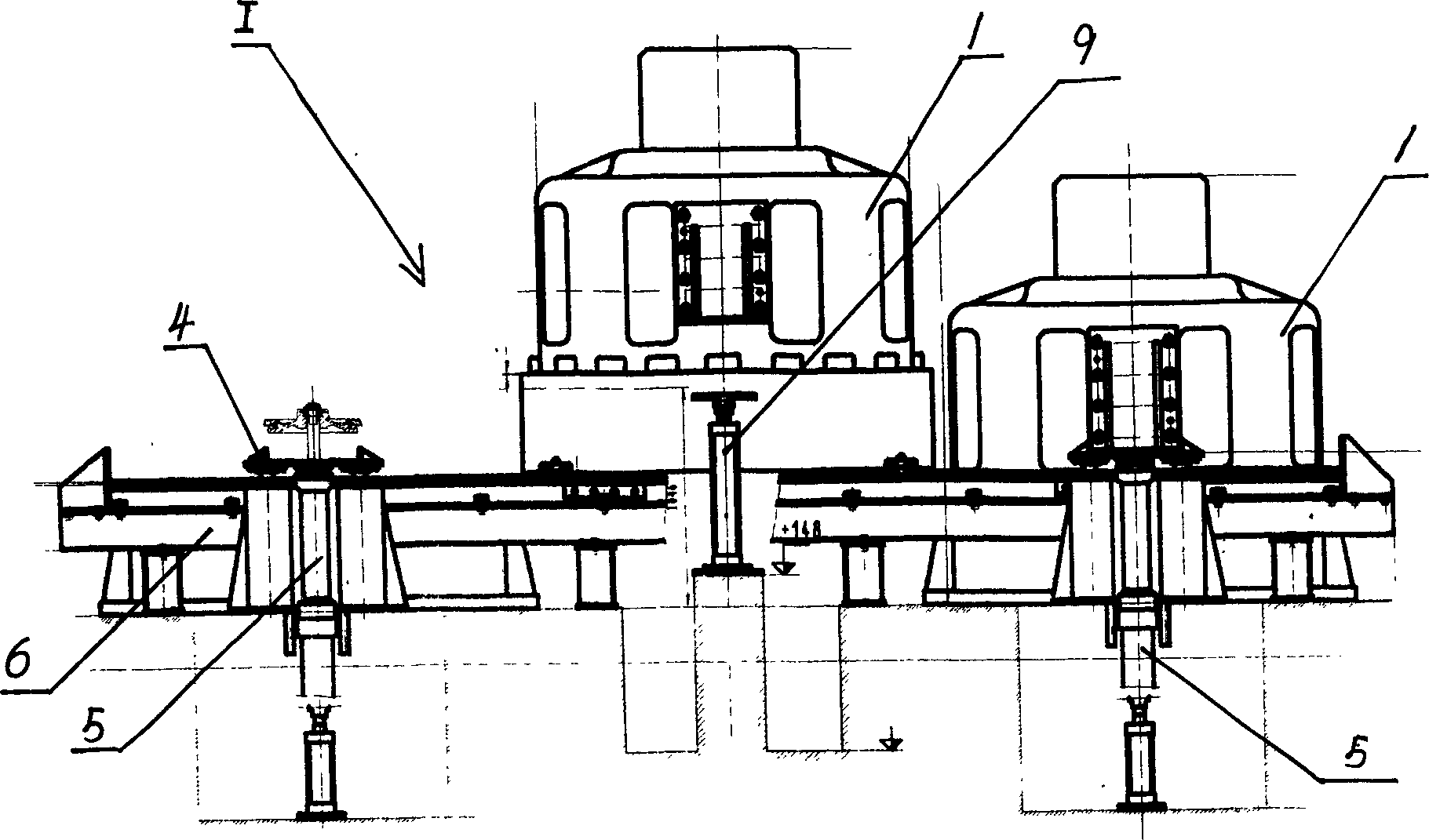

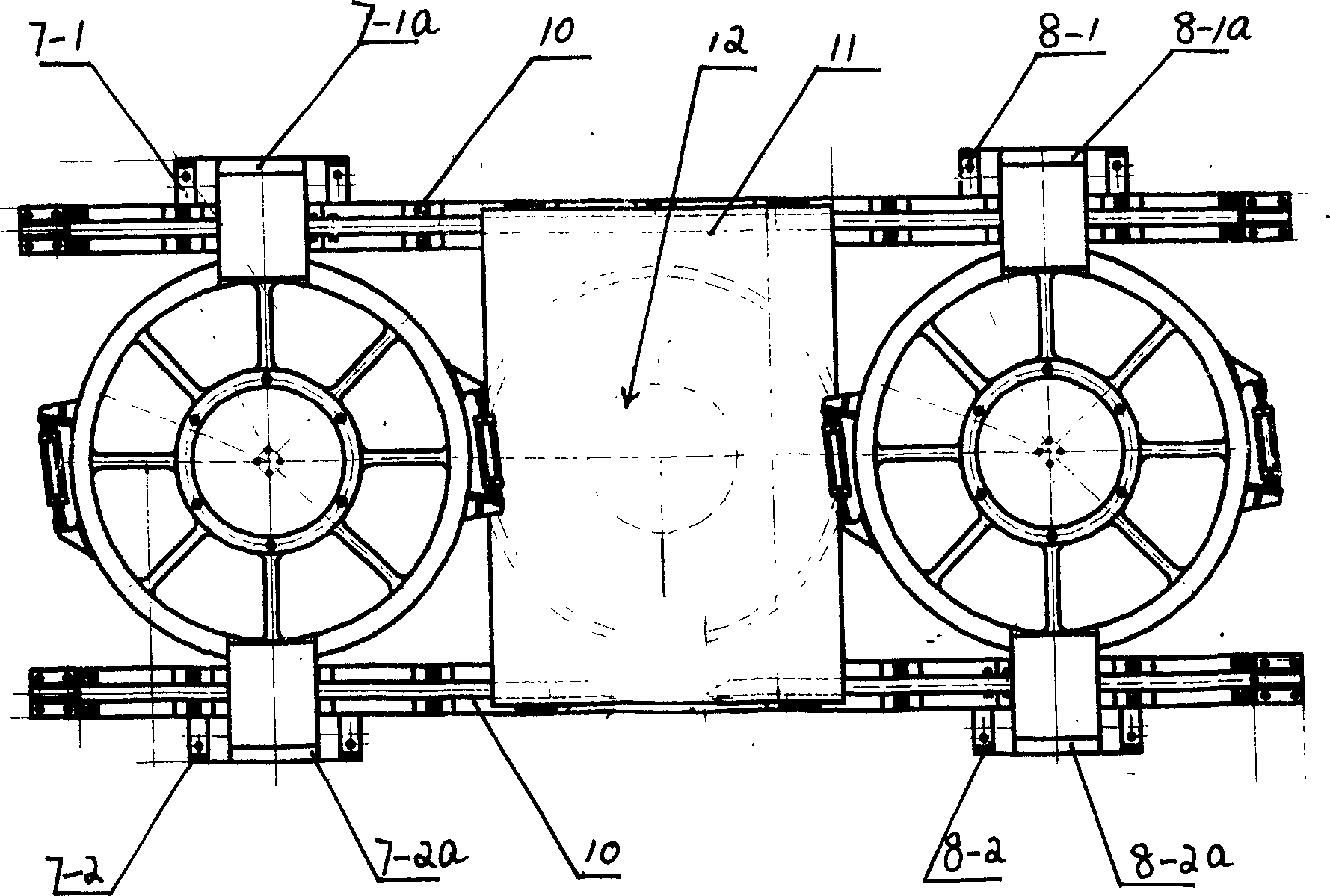

[0028] Such as figure 2 , image 3 As shown, the vertical lifting and parallel shifting radial tire vulcanizing machine I, the "one"-shaped frame 6 is installed on the ground, its length is 6500mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com