Process for preparing dimethomoph

A technology of dimethomorph and synthesizing dimorpholine, applied in the direction of organic chemistry, etc., can solve the problem of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

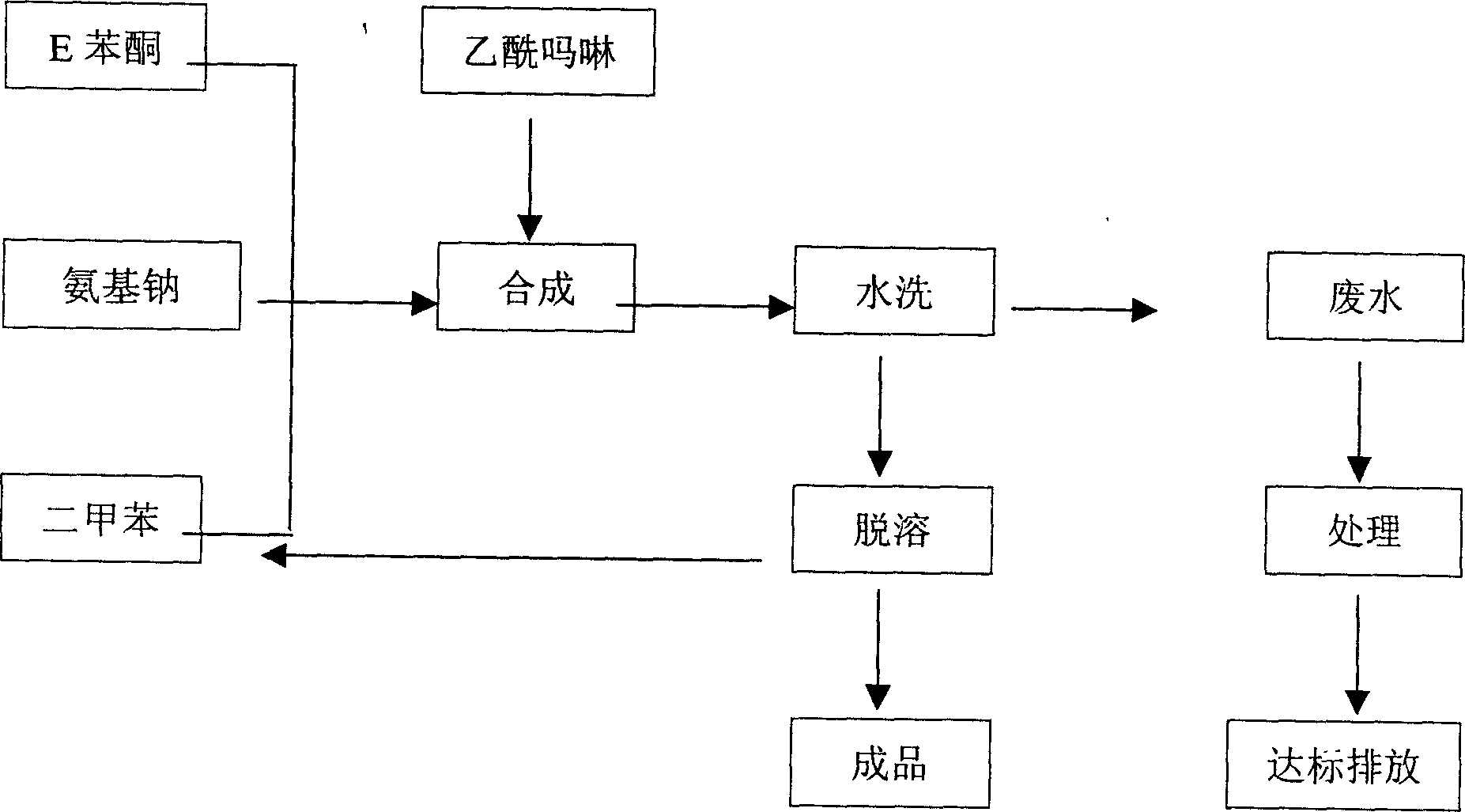

[0027] Embodiment 1, with reference to figure 1 :

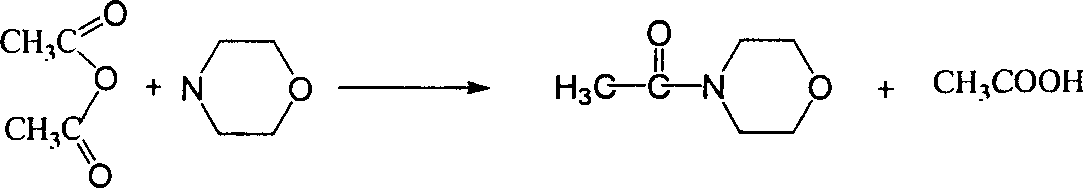

[0028] Preparation of acetylmorpholine:

[0029] Put the measured xylene and acetic anhydride into the enamel reaction kettle, turn on the cooling water and stir, add dropwise the morpholine that has been pumped into the high-level tank at room temperature, slowly raise the temperature to 110°C after the dropwise addition, and then pour in after reflux for 5 hours. Desolventization of the still and by-product acetic acid, the remaining part in the still is the intermediate acetylmorpholine, the content is 99%, and the yield is ≥90.2%

[0030] batch number

[0031] Preparation of dimethomorph:

[0032] Put xylene, E-benzophenone and sodium amide into the reaction kettle, stir and add the acetylmorpholine that was pumped into the high level tank in advance when the temperature is raised to 100°C, after the dropwise addition, heat up to reflux and keep it warm for 2 hours, and then cool down to 80 After ℃, put the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com