Rapeseed extrusion expanding processing method and processing device for pretreatment of oil extraction and preparation

A technology of extrusion and processing methods, applied in the direction of fat oil/fat production, fat generation, etc., can solve the problems of large degree of protein denaturation, inconvenient cleaning, adjustment, maintenance of screws and sleeves, and reduction of the value of protein in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation

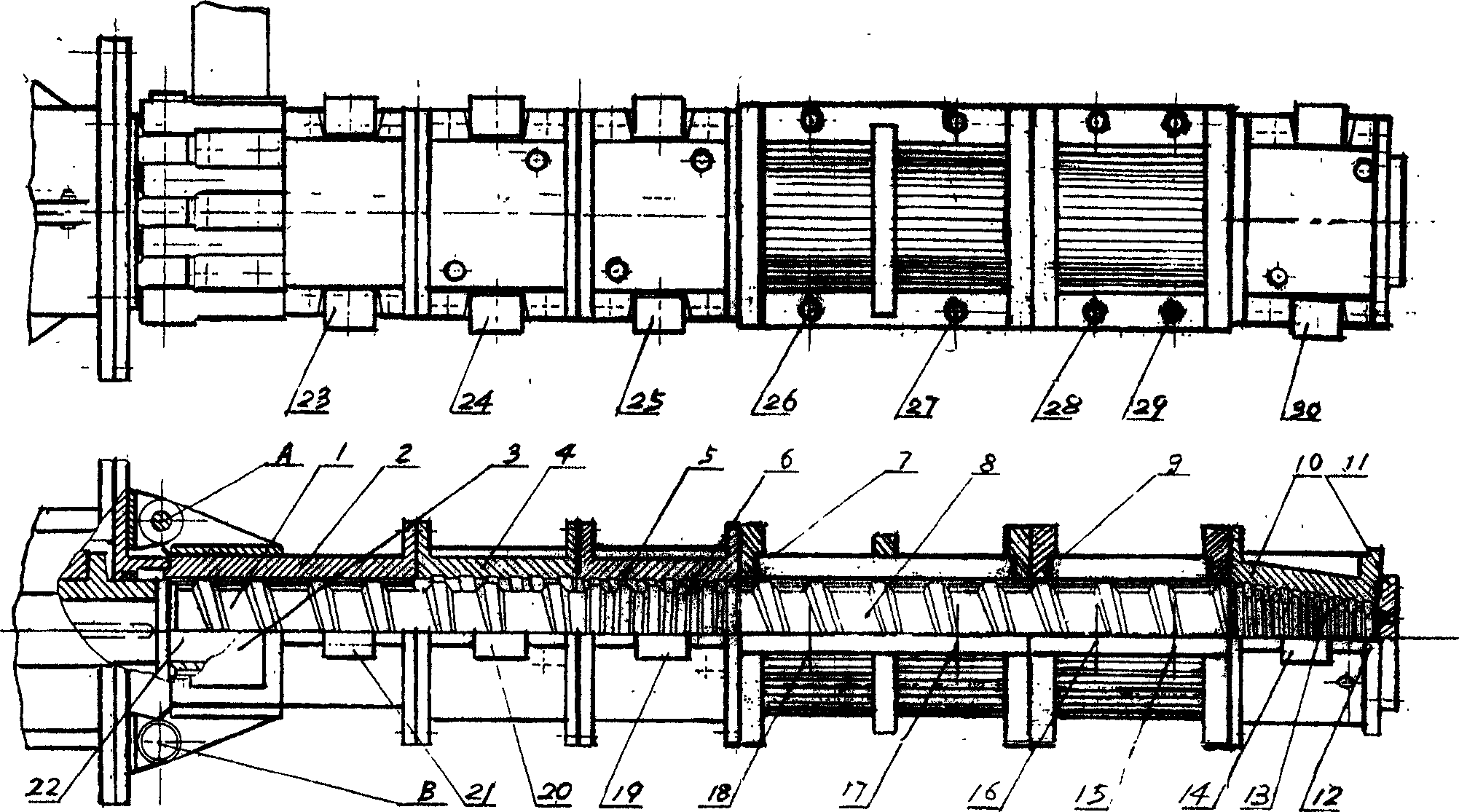

[0017] Embodiments of the present invention: Below in conjunction with the accompanying drawings, the implementation of the present invention will be further described.

[0018]After the rapeseed is cleaned, if its water content is higher than 10%, it is dried at low temperature to make its water content ≤ 10%, and then crushed or shelled with shells to obtain rapeseed kernels with a shell content of ≤ 5%. Crushed shells (with a particle size of 0.6mm~1.0mm) or shelled rapeseed kernels enter the extrusion device through the feeding port 3 (see the attached picture). The outer surface of the three-section screw 8, the fourth-section screw 13 and the first sleeve 2, the second sleeve 4, the third sleeve 5, the first squeeze cage 7, the second squeeze cage 9, the first squeeze cage In the extrusion chamber formed by the inner surface of the four-section sleeve 10, the main shaft 22, the first section screw 1, the second section screw 6, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com