Process for making enclosed type incandescent lamp with infrared reflection reducing coating and process for preparing infrared reflection reducing coating

An infrared anti-reflection coating and closed technology, which is applied to lighting and heating equipment, parts of lighting devices, safety devices of lighting devices, etc., can solve the problem of cracking of the closed incandescent lamp screen and cone seal, and achieve Reduce light attenuation, solve the effects of screen frying and screen temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

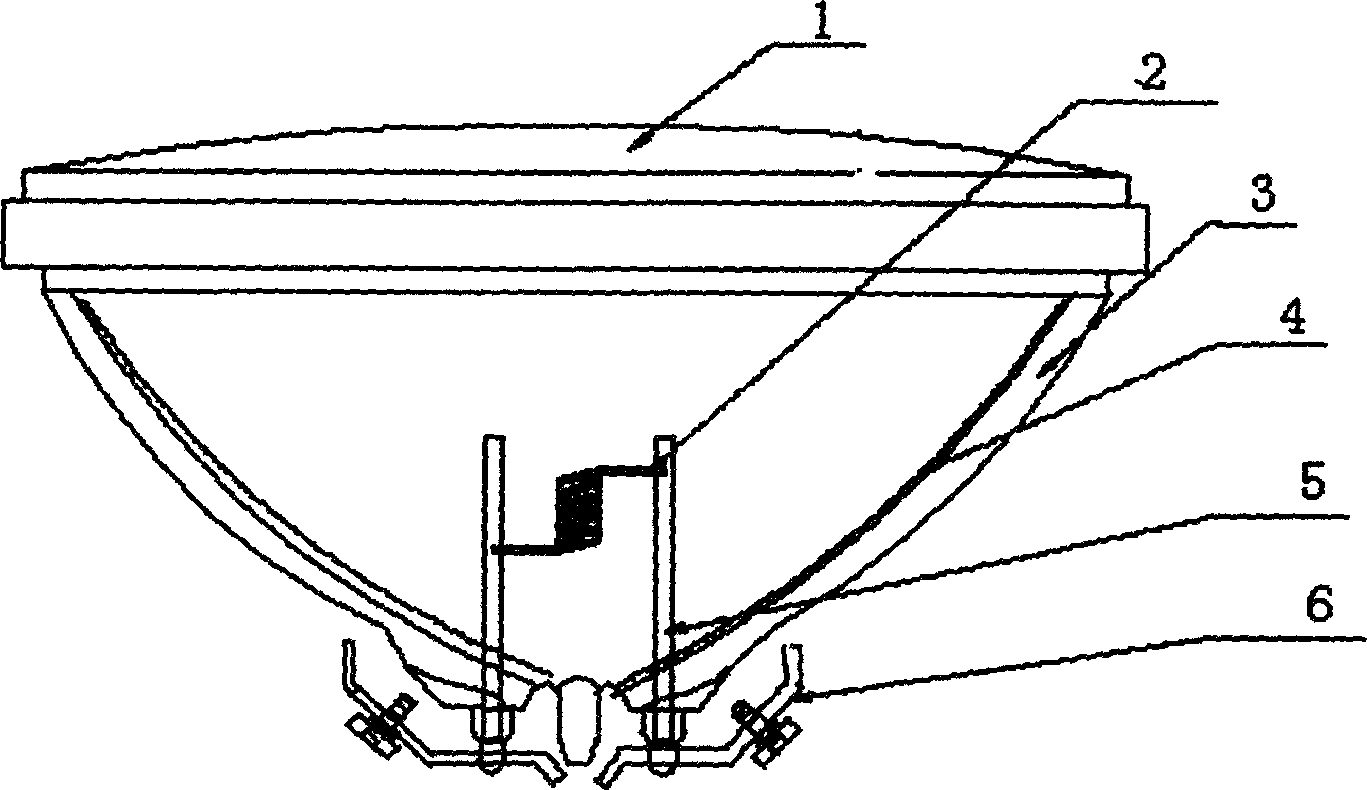

[0017] The infrared anti-reflection film enclosed incandescent lamp is composed of a lens (or screen) 1, a luminous body 2, a reflector (commonly known as "cone") 3, an infrared anti-reflection film 4, a guide wire 5 and a contact piece 6, and the illuminant 2 is welded A mounting part is formed on the guide wire 5, and placed on the focal point of the reflector (commonly known as "cone") 3, the inner surface of reflector (commonly known as "cone") 3 is a paraboloid, and the inner wall of the paraboloid is coated with an infrared anti-reflection film 4, and the lens (or screen) 1 and the reflector (commonly known as "cone") 3 are edge sealed to form a sealed glass cavity, and then the air is exhausted on the exhaust car and filled with inert gas to seal it off, and finally the contact piece is welded on the lead-out electrode 6.

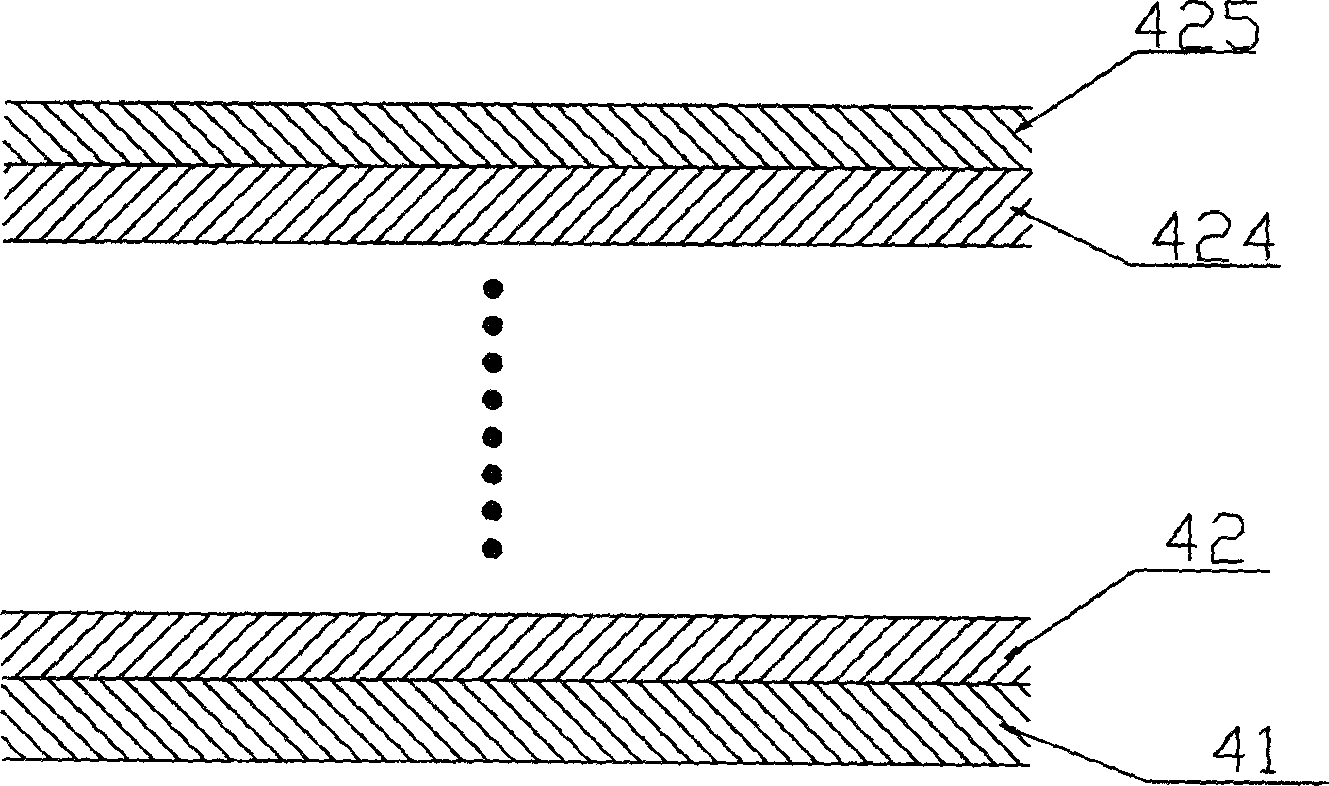

[0018] In the present embodiment, the infrared anti-reflection film 4 is formed by alternately and uniformly vapor-depositing ZnS coating and SiO on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com