Method for hydrogenation preparation of 4-amino-3-fluorophenol from o-fluoro-nitrobenzene and device therefor

A technology for o-fluoronitrobenzene and fluorophenol, which is applied in the field of nitrobenzene hydrogenation to produce 4-aminophenol, can solve problems such as difficult separation of catalysts, and achieve the effects of reducing reaction costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

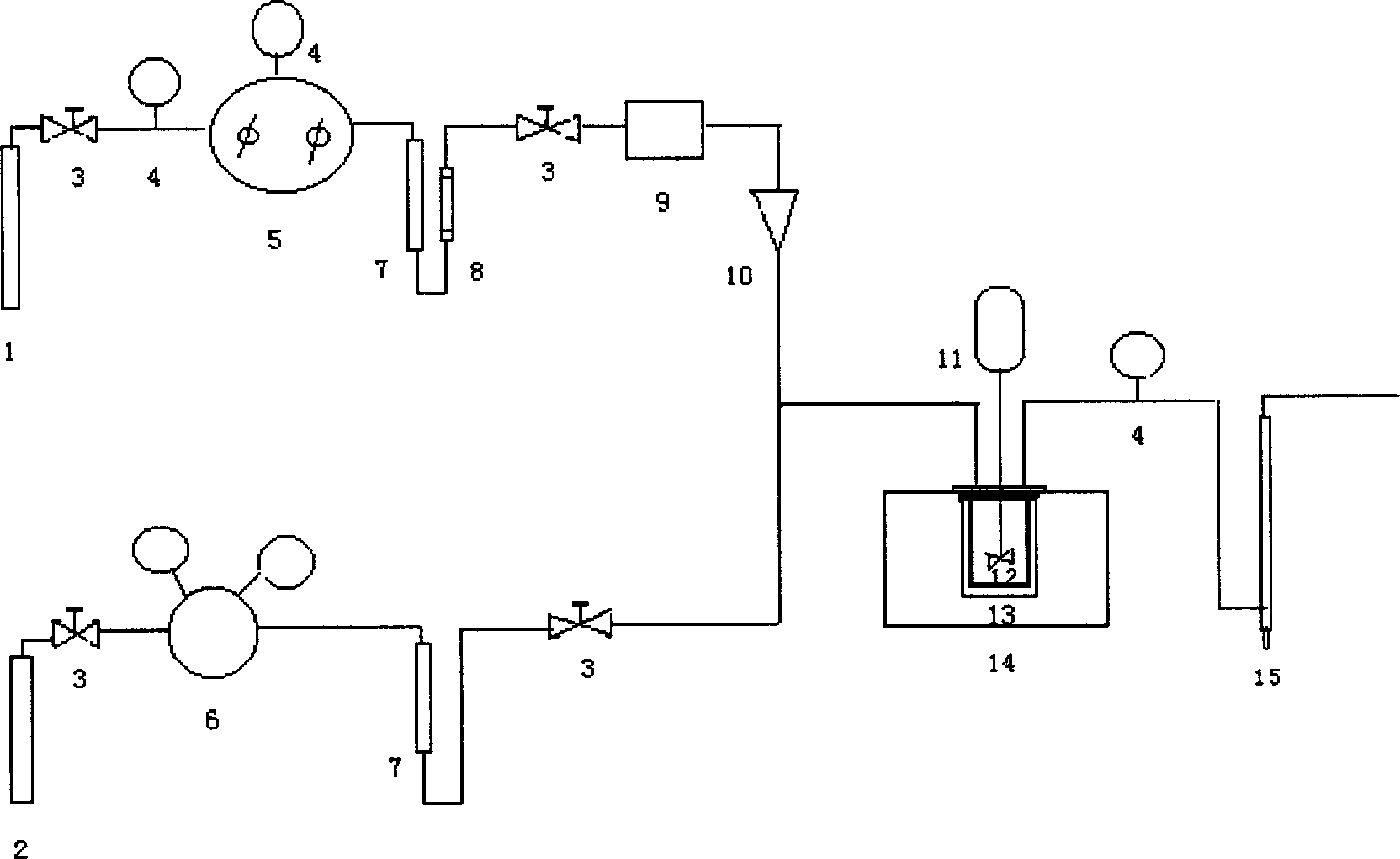

[0017] Such as figure 1 Shown, the 500ml stainless steel reactor 13 that has magnetic stirrer 11 is arranged in the oil bath 14, and reactor 13 is provided with air inlet and exhaust hole, is provided with the liner 12 of polytetrafluoroethylene material in it, On the gas line between the hydrogen source 1 and the reactor 13, a shut-off valve 3, a pressure gauge 4, a pressure regulator 5, a purification tank 7, a filter 8, a mass flow meter 9 and a one-way valve 10 are arranged; 2 and the gas pipeline between the reactor 13 are provided with a shut-off valve 3, a pressure reducing valve 6 and a purification tank 7; on the exhaust pipeline connected with the reactor 13 vent hole, a pressure gauge 4 and 15 are arranged to be soap scum flow meter.

[0018] In reactor 13, add 10.8 gram o-fluoronitrobenzene respectively, 173ml deionized water, 7.7ml absolute ethanol, 10.4 gram vitriol oil, 0.426 gram platinum loading is 2wt.%Pt-C catalyst, and reaction temperature is 90 °C, the p...

Embodiment 2

[0020] Reaction temperature is changed into 80 ℃ and other conditions are identical with example 1, and other steps are with example 1.

Embodiment 3

[0022] Reaction temperature is changed into 100 ℃ and other conditions are identical with example 1, and other steps are with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com