Process for preparing organic montmorillonite / mineral wax composite energy-storage material

A composite energy storage material and organic montmorillonite technology, which can be used in heat exchange materials, chemical instruments and methods, etc., can solve the problems of reduced surface polarity, low heat storage value, and limited wide use, etc. Capacitance, cost reduction, and difficult to parse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

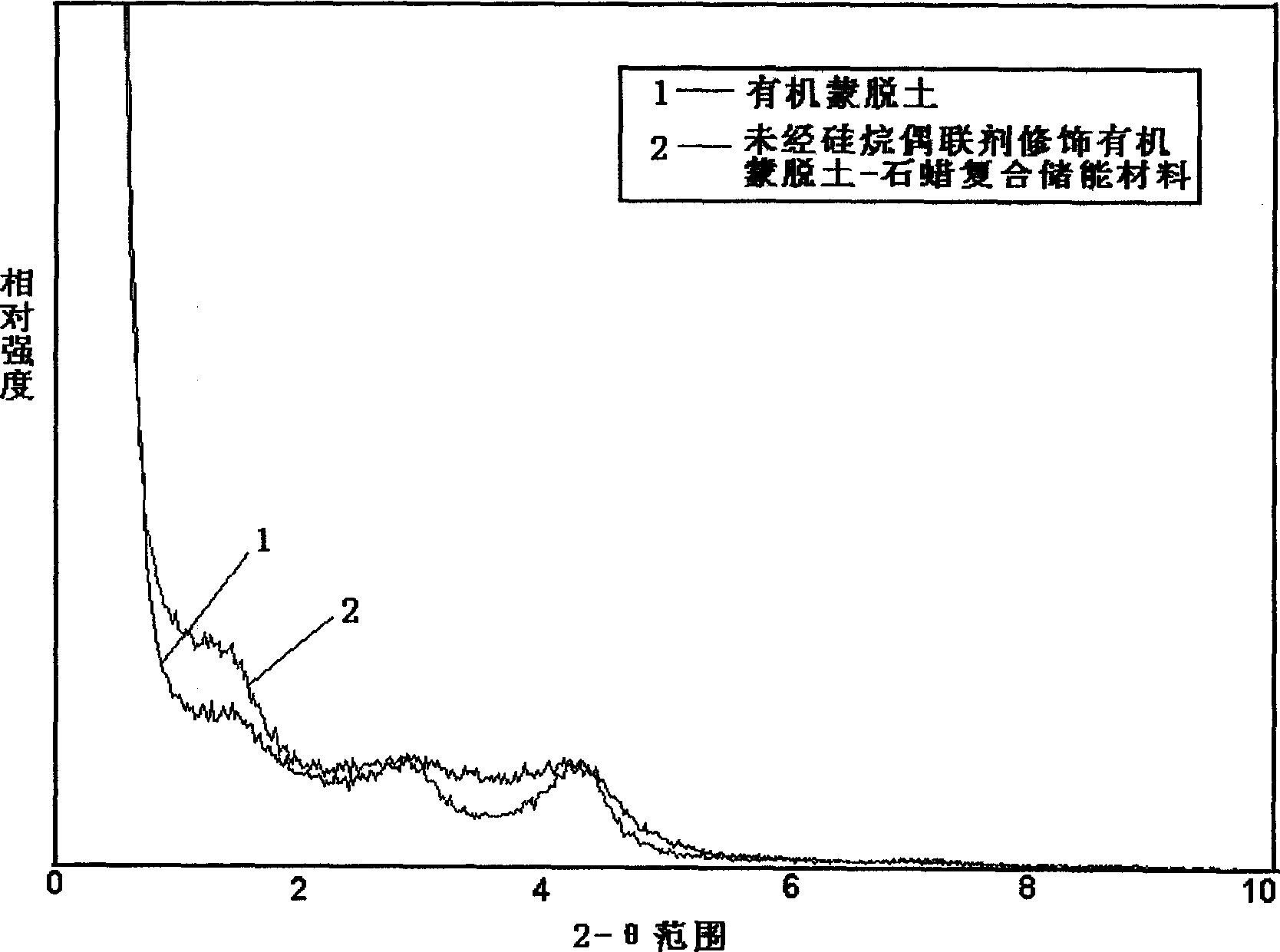

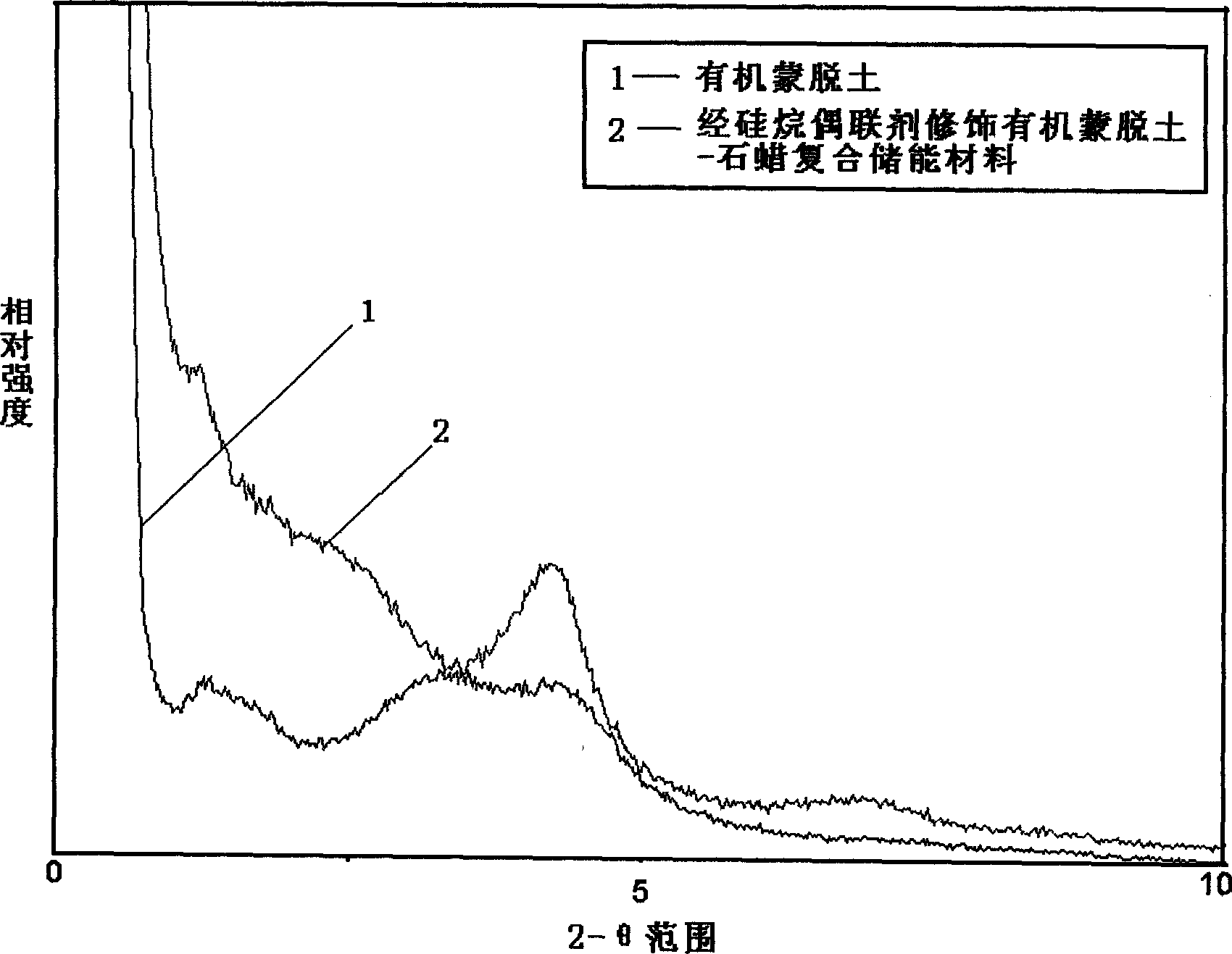

[0019] The intercalation type composite energy storage material prepared by the present invention is tested with a differential scanning calorimeter to store heat, the differential scanning calorimeter is Pyris Diamond (PE in the United States), the test atmosphere is high-purity nitrogen, and the temperature test range is 0 ~100°C, scan rate 5K / min; use X-ray diffraction (XRD) to analyze its microstructure, XRD uses D8ADVANCE (Bruker, USA), light source is Cu ray source, 2θ range is 0.5-30°, step size is 0.02 °; and observe the appearance of its heat storage and release process by placing it at 15-25 °C higher than the melting point of the paraffin used for 72 hours.

[0020] Table 1 is the preparation method of 2 comparative examples and 3 implementation examples. Table 2 is the various performances of the composite materials prepared by various implementation examples. From the performance data in the table, it can be seen that the composite material prepared by the organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com