Test circuit and test method for earth resistance

A grounding resistance and testing circuit technology, applied in the direction of grounding resistance measurement, etc., can solve problems such as large errors, achieve the effects of improving accuracy, simplifying the testing process and workload, and solving high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

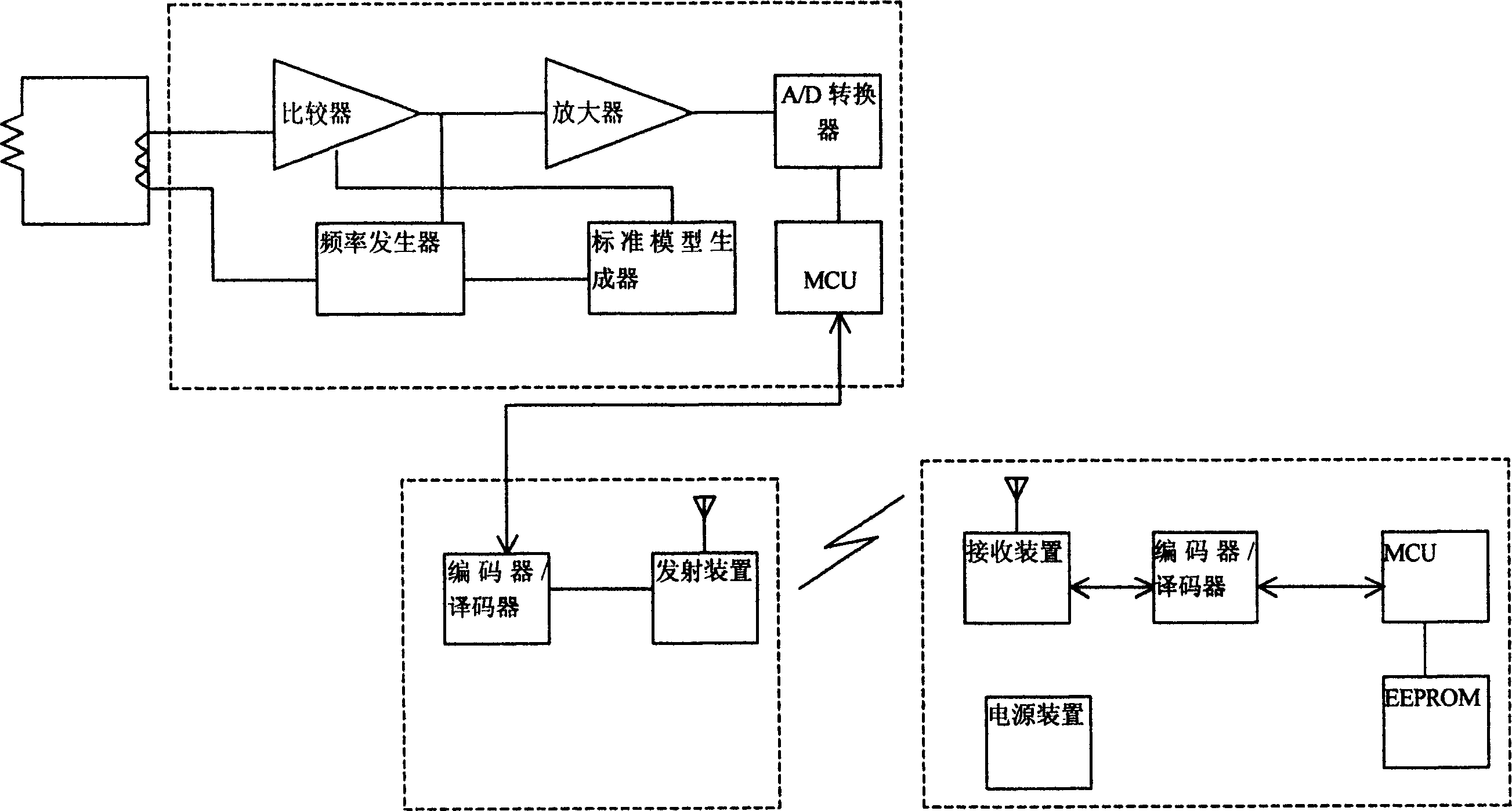

[0024] like image 3 Shown is the circuit principle block diagram of the present invention. The invention mainly includes a ground resistance testing unit, a testing result transmitting unit and a testing result receiving unit. Among them, the ground resistance test unit mainly includes a microprocessor, a frequency generator, a scanning power amplifier, a jaw coil, a standard model generator, a comparator and an A / D converter (analog-to-digital converter). The jaw coil is connected to both ends of the ground resistance to be measured, and can receive damping information of the ground resistance to be measured. The joint lead-out wire of jaw coil is respectively connected on frequency generator and comparator, and described frequency generator is used for generating scanning frequency; And can generate the standard model that is used for comparison in standard model generator, this standard model generator and The data obtained by the jaw coil will be compared with a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com