Brushless permanent magnet motor or alternator with variable axial rotor/stator alignment to increase speed capability

A permanent magnet motor and magneto technology, which is applied to synchronous motors with stationary armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc., and can solve the problems of reducing the back electromotive force of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

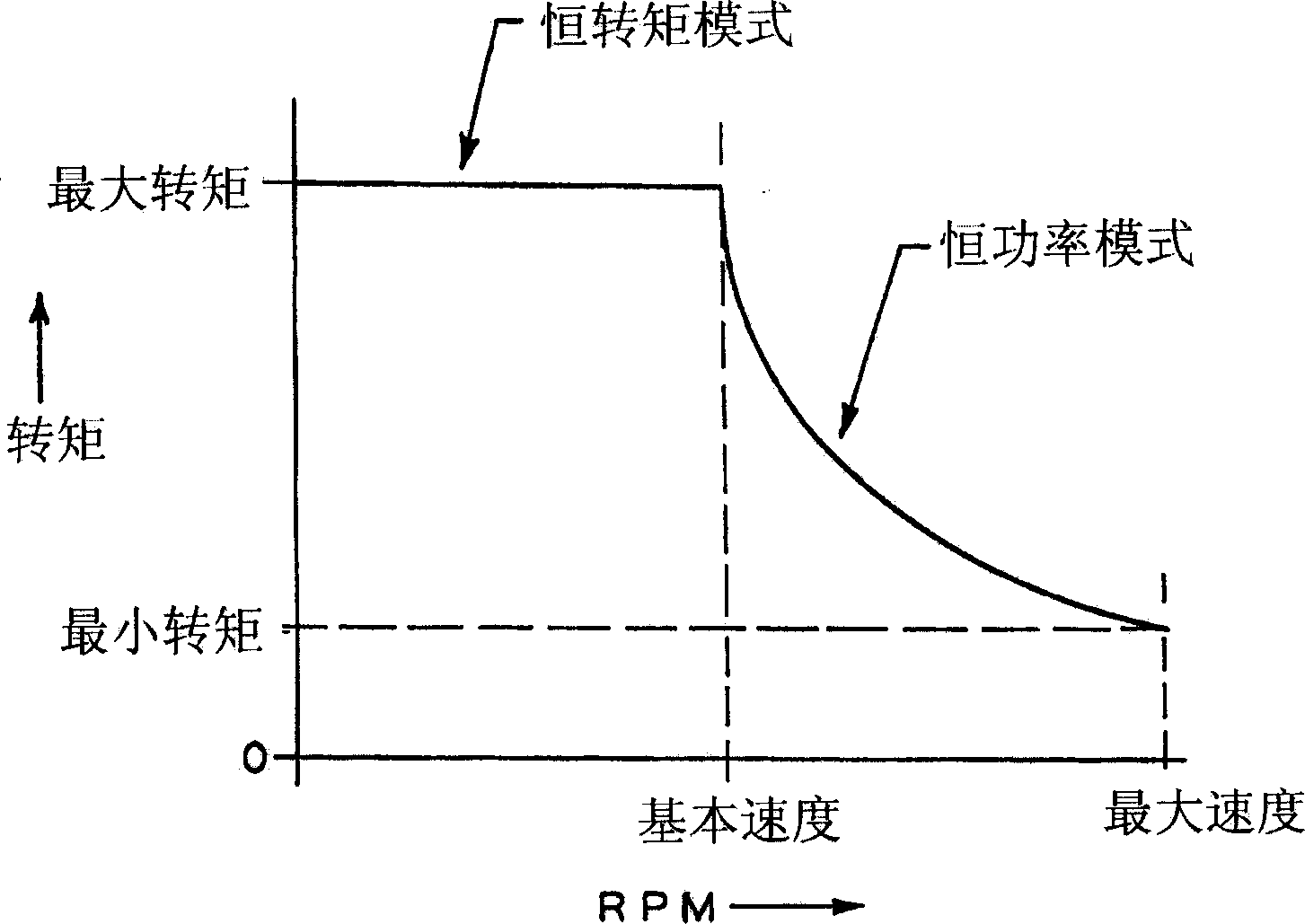

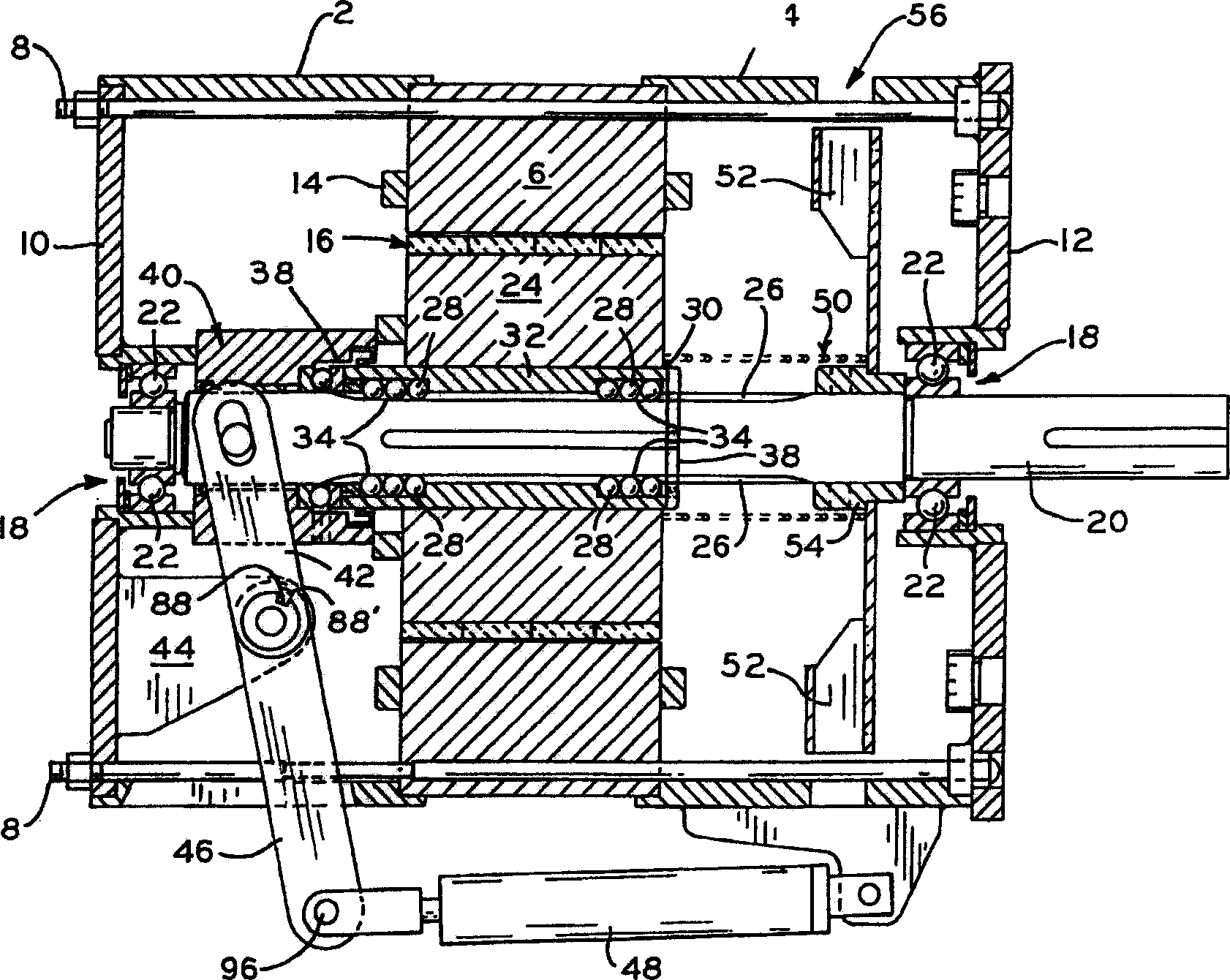

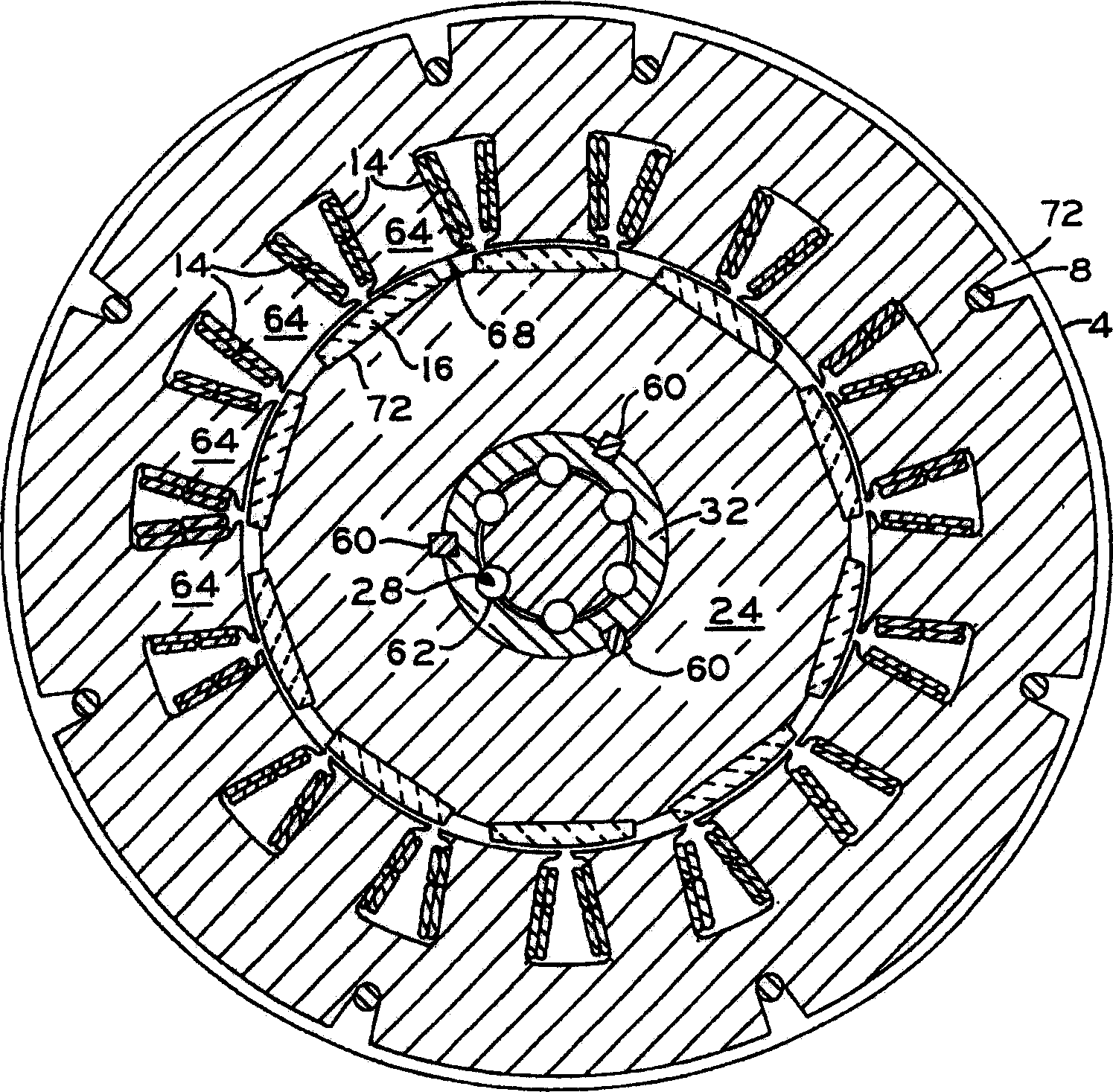

[0034] Many applications desire the advantages of brushless permanent magnet motors but require operation well beyond their base speed. In electric vehicle applications, low-speed operation often requires constant torque below base speed to tow heavy loads, or to traverse rough terrain or hill-like slopes. In many cases, high-speed operation requires double or triple the base speed for driving on level roads or underdeveloped industrial areas. In this high speed mode, very little torque is required and constant power operation is expected. Available torque is inversely proportional to speed in constant power operation. In electric motors equipped with mechanical means to control the back EMF, the constant power mode provides an operation similar to variable speed in a transmission, ie, trading low available torque for high speed. The electric motor of the present invention can be used as a magnetic variable transmission, which is capable of switching from a constant torque m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com