Method and special tester for heat exchanging ability of underground pipe heat exchanger

A buried tube heat exchanger and heat exchange capacity technology, applied in the direction of measuring devices, geothermal power generation, machine/structural component testing, etc., can solve the inconvenience of moving, unsuitable for engineering construction testing, and can only be tested at the same time and other problems, to achieve the effect of correct and clear principle, simple structure and easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

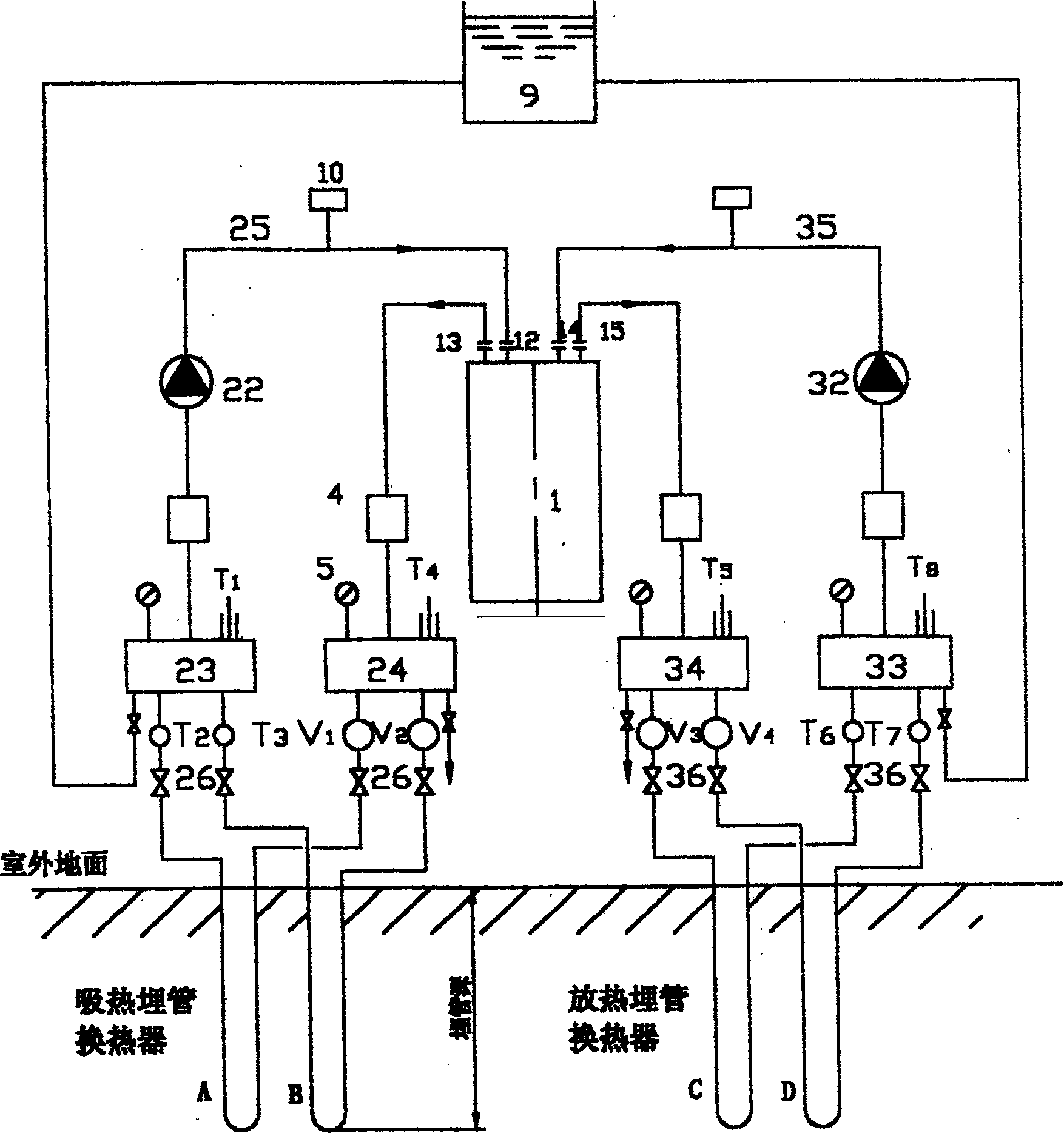

[0027] The new method for testing the heat exchange capacity of the buried tube heat exchanger of the present invention and its special testing device are further described below in conjunction with the accompanying drawings:

[0028] See attached figure 1 , in this example: 1. Ground source heat pump host, 1 unit; 22, 32, circulating water pump, 2 units; 23, 24, 33, 34, water separator and water collector, 4 units; 4, Y-type decontamination 5, pressure gauge, 4 pieces; T thermometer socket and thermometer, 8 pieces; V, turbine flowmeter, 4 pieces; 26, 36, ball valve, 8 pieces; 9, expansion tank, 1 piece; 10 , Automatic exhaust valve, 2 pieces; 25, 35, system piping; A, B, heat-absorbing buried pipe radiator, 2 pieces; C, D, heat-releasing buried pipe heat exchanger, 2 pieces.

[0029] There are 4 heat exchangers in this example, two of which are endothermic heat exchangers and two are heat exothermic heat exchangers;

[0030] There are 4 decontamination devices in this exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com