Preparation equipment for broken worn-out printed circuit board base plate material granules regeneration plate

A technology for printed circuit boards and substrates, applied in the field of industrial waste treatment and resource utilization, can solve the problems of complex process, secondary environmental pollution and high cost, and achieve the effect of simple process and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

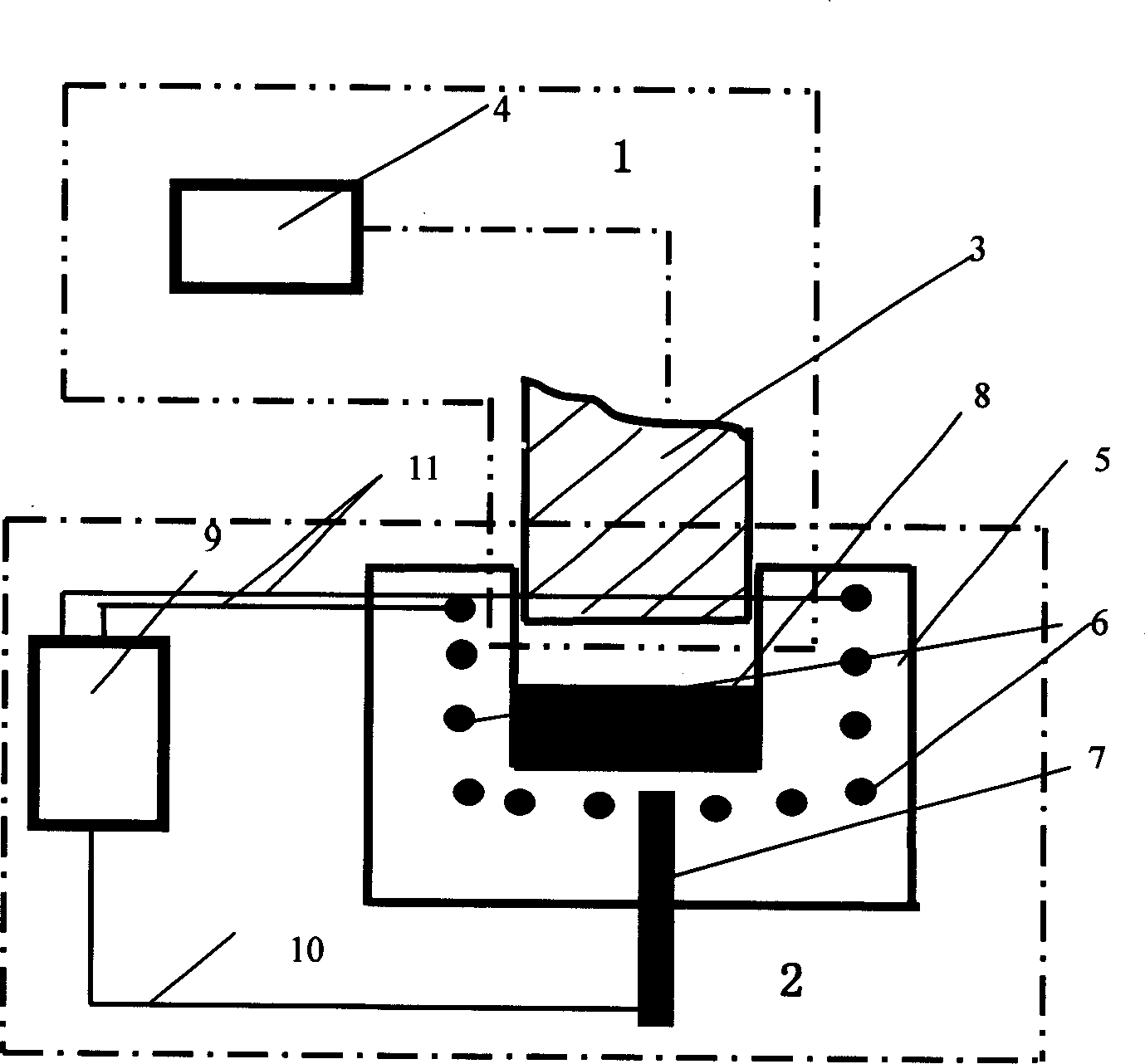

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The device structure of the present invention is as figure 1 As shown, it includes two parts: hydraulic system 1 and heating forming mold system 2, wherein hydraulic system 1 includes hydraulic press 4 and pressure head 3, and heating forming mold system 2 includes mold 5, heating body 6, thermocouple 7, heating power supply and temperature control equipment9.

[0017] The hydraulic machine 4 is connected with the pressure head 3, and the pressure is applied to the pressure head 3 by adjusting the oil pressure, so as to pressurize the substrate material particles 8 of the waste printed circuit board in the mold 5. The heating body 6 and thermocouple 7 are placed in the mold 5, the heating power supply and temperature control equipment 9 are connected to the heating body 6 and the thermocouple 7, and the substrate material particles 8 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com