Immersion lithography system, and method of performing irradiation to semiconductor structure having a photoresistive layer

An immersion lithography and photoresist layer technology, applied in the immersion lithography system and the field of immersion fluid, can solve the problem that the pH value is not further controlled, and achieve the effect of inhibiting pollution, inhibiting dissolution and reducing damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following are preferred embodiments of the present invention to illustrate the immersion photolithography system and its usage according to the present invention.

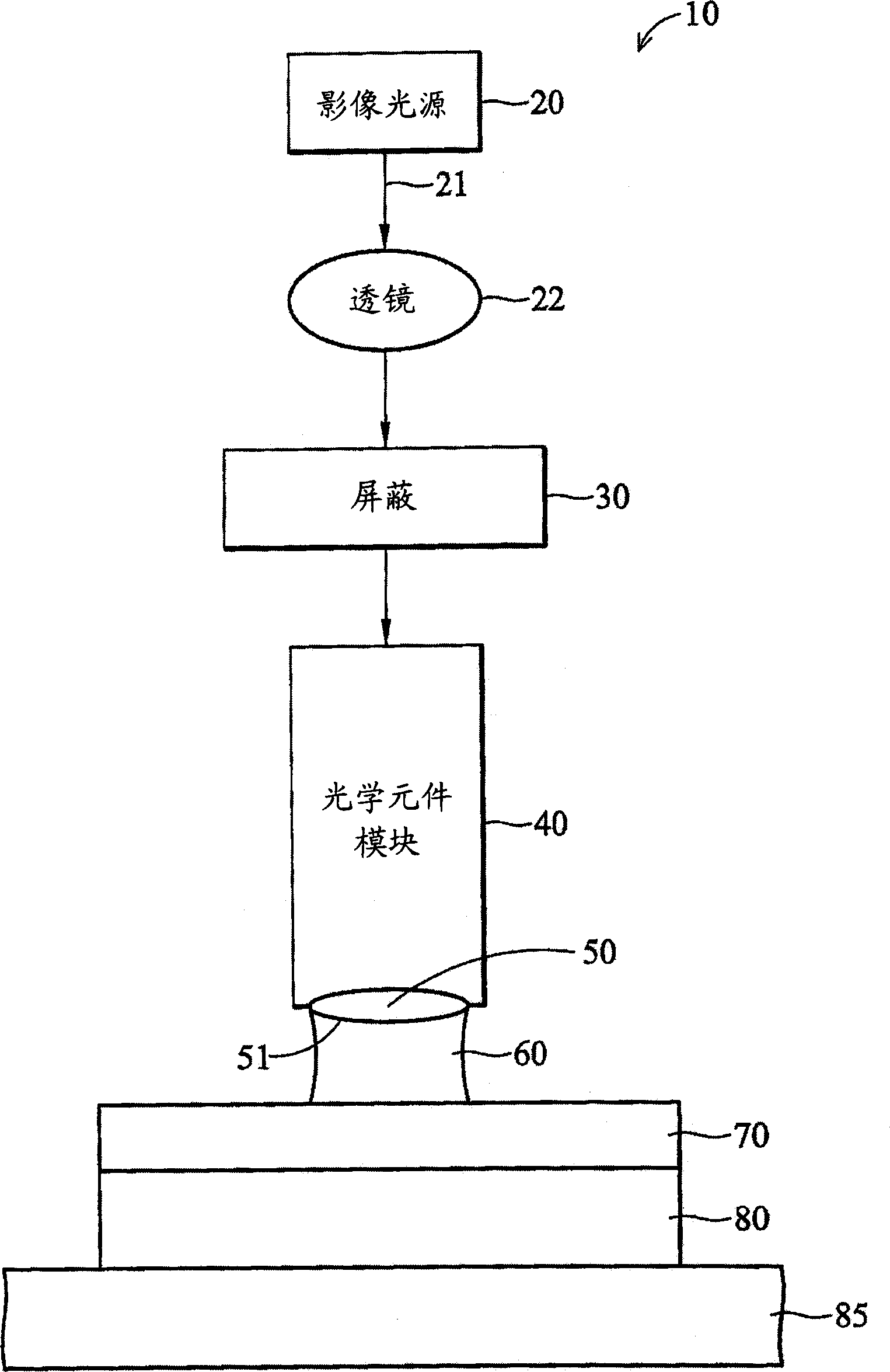

[0063] figure 1 is a schematic diagram of one embodiment of an immersion lithography system 10 . The immersion lithography system 10 includes an image light source 20, the light source 20 emits a light energy beam 21, and passes through a lens 22, then the light energy beam 21 passes through a shield 30 and an optical element module 40, and finally passes through a The outermost lens 50 of the optical surface 51 . The space between the outermost lens 50 and the photosensitive material 70 formed on the semiconductor element substrate 80 is filled with the immersion fluid 60 .

[0064] In a preferred embodiment, the semiconductor element substrate 80 may be a semiconductor substrate on which an integrated circuit is formed. For example, the semiconductor element substrate 80 may be a silicon substrate (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com