Arm rack motion controller of concrete pump truck

A technology of motion controller and concrete pump truck, applied in digital control, computer control, electrical program control and other directions, can solve the problem of multi-axis motion controller being unable to connect to the bus and inconvenient for communication, and achieve the convenience of long-distance information transmission and energy consumption. Less and faster operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

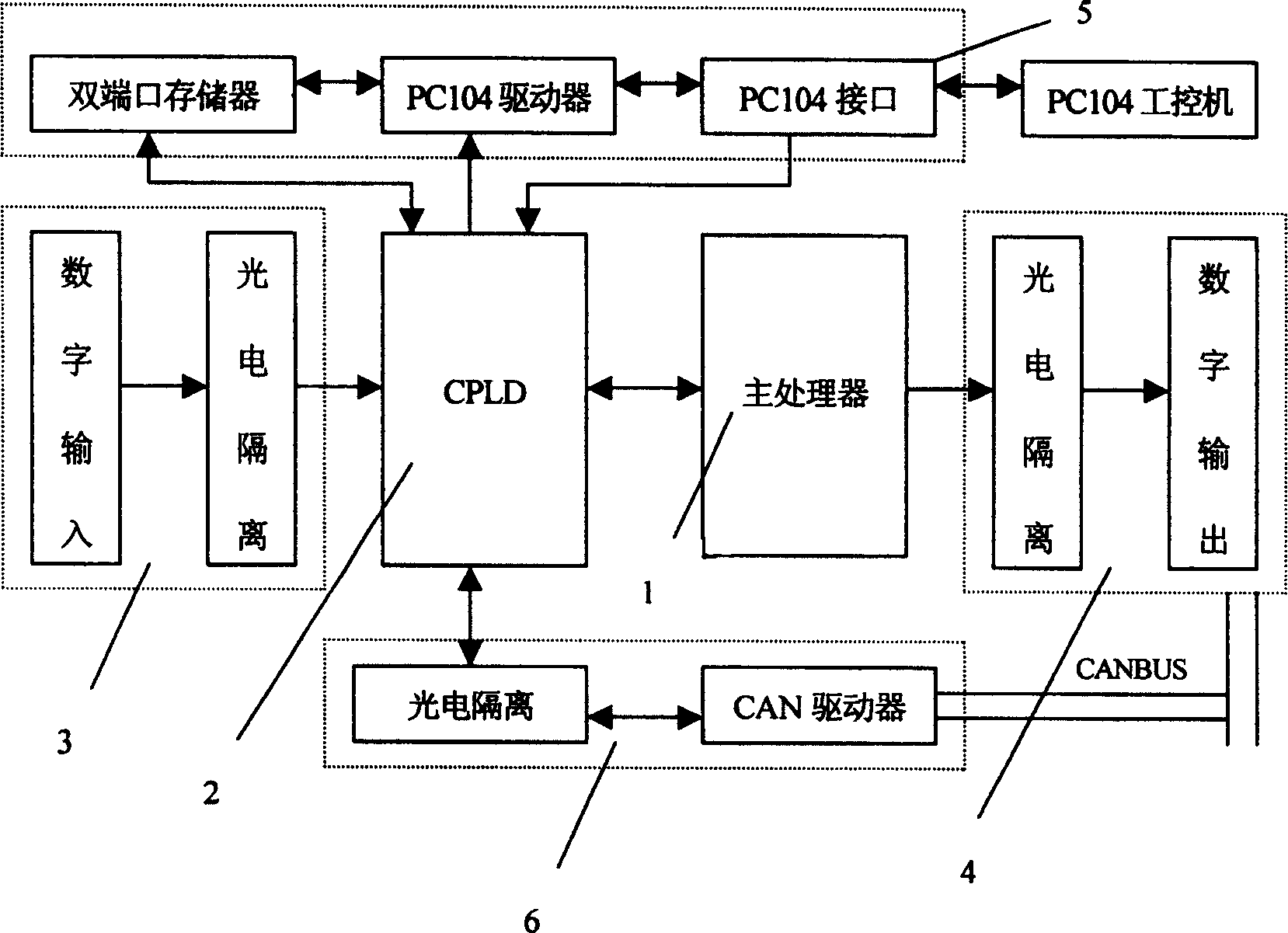

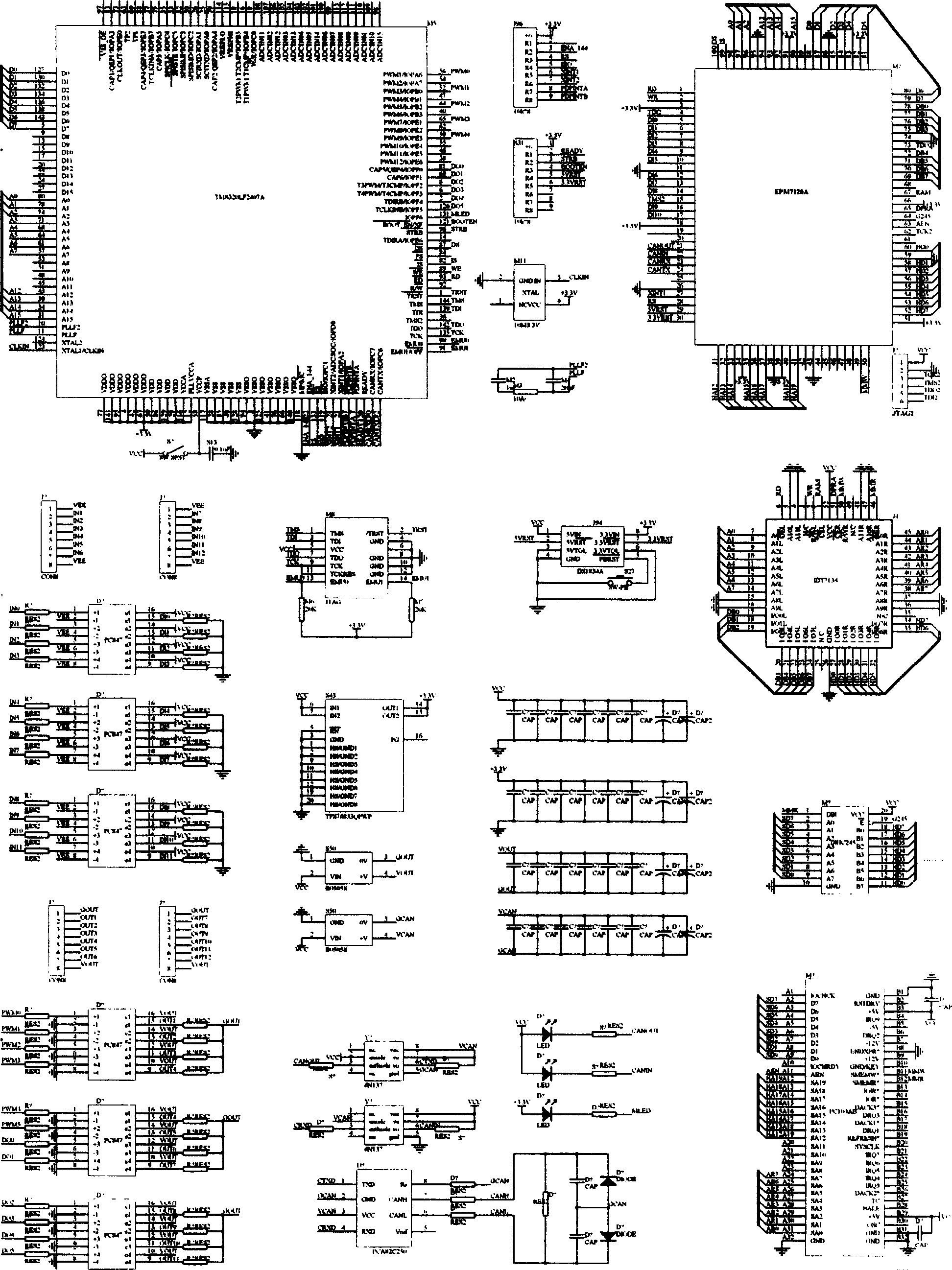

[0021] Such as figure 1 The basic structure of the present invention shown, it adopts high-speed DSP main processor 1, large-scale CPLD and CAN bus communication technology, provides a kind of multi-axis motion control device based on PC104 bus and CAN bus. Such as figure 1 Shown, the present invention it comprises DSP main processor 1, CPLD bus decoding and level converter 2, digital input module 3, digital output module 4, DSP main processor 1 and CPLD decoding and level converter 2 and The digital output module 4 is connected, the CPLD decoding and level shifter 2 is connected with the digital input module 3 , and the CPLD decoding and level shifter 2 is also connected with the PC104 bus interface module 5 and the CAN bus interface module 6 . PC104 bus interface module 5 comprises dual-port memory, PC104 bus driver and PC104 bus interface; PC104 bus inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com