Nonferrous metal powder

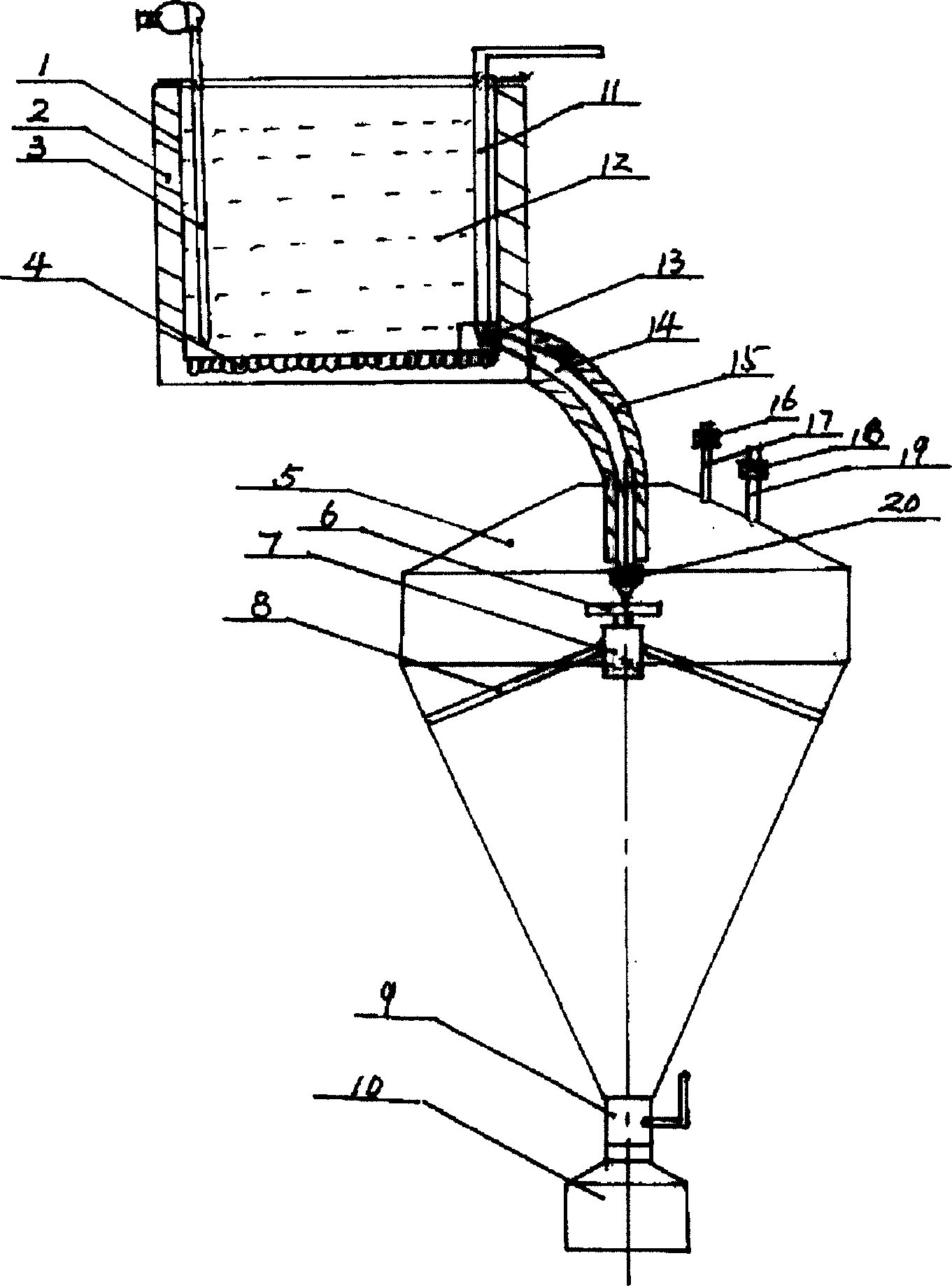

A high-speed centrifugal and atomization device technology, which is applied in the field of non-ferrous metal powder preparation technology and devices, can solve the problems of irregular product shape, wide particle size distribution range, high oxygen content, etc., and achieve narrow particle size distribution and high oxygen content. The effect of low cost, high production efficiency and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using the above-mentioned powder making device, the spherical solder with the composition of 63% Sn and 37% Pb is prepared. The main process parameters to be controlled and adjusted are: melting temperature 230-250°C, atomization temperature 210-230°C, melting during atomization Liquid flow rate: 150kg / h, atomization disc diameter 50mm, atomization speed 20000~40000r / min, oxygen atmosphere: 20~60ppm.

[0027] The products prepared according to the above parameters are tested to have high roundness, bright surface without defects, oxygen content: <50ppm, and the particle size distribution is as follows:

[0028] %<10 25 50 75 90

[0029] um 12.96 25.06 37.39 50.78 66.86

Embodiment 2

[0031] The composition is 97%Bi3%Sb, 58%Bi42%Sn and other metals and alloy powders prepared according to the method and steps of Example 1. Only the melting temperature of the alloy is superheated by 30-70°C according to the requirements, and the other parameters remain unchanged. The obtained product particle size and distribution, morphology, oxygen content, etc. are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap