Environmental protection new-standard exhauster capable of collecting exhaust noise and black smoke carbon deposite of one-cylinder diesel tractor

A technology for exhaust noise and tractors, which is applied in the direction of exhaust devices, machines/engines, mechanical equipment, etc., to achieve the effects of small smoke, reduced odor, and wide capture and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

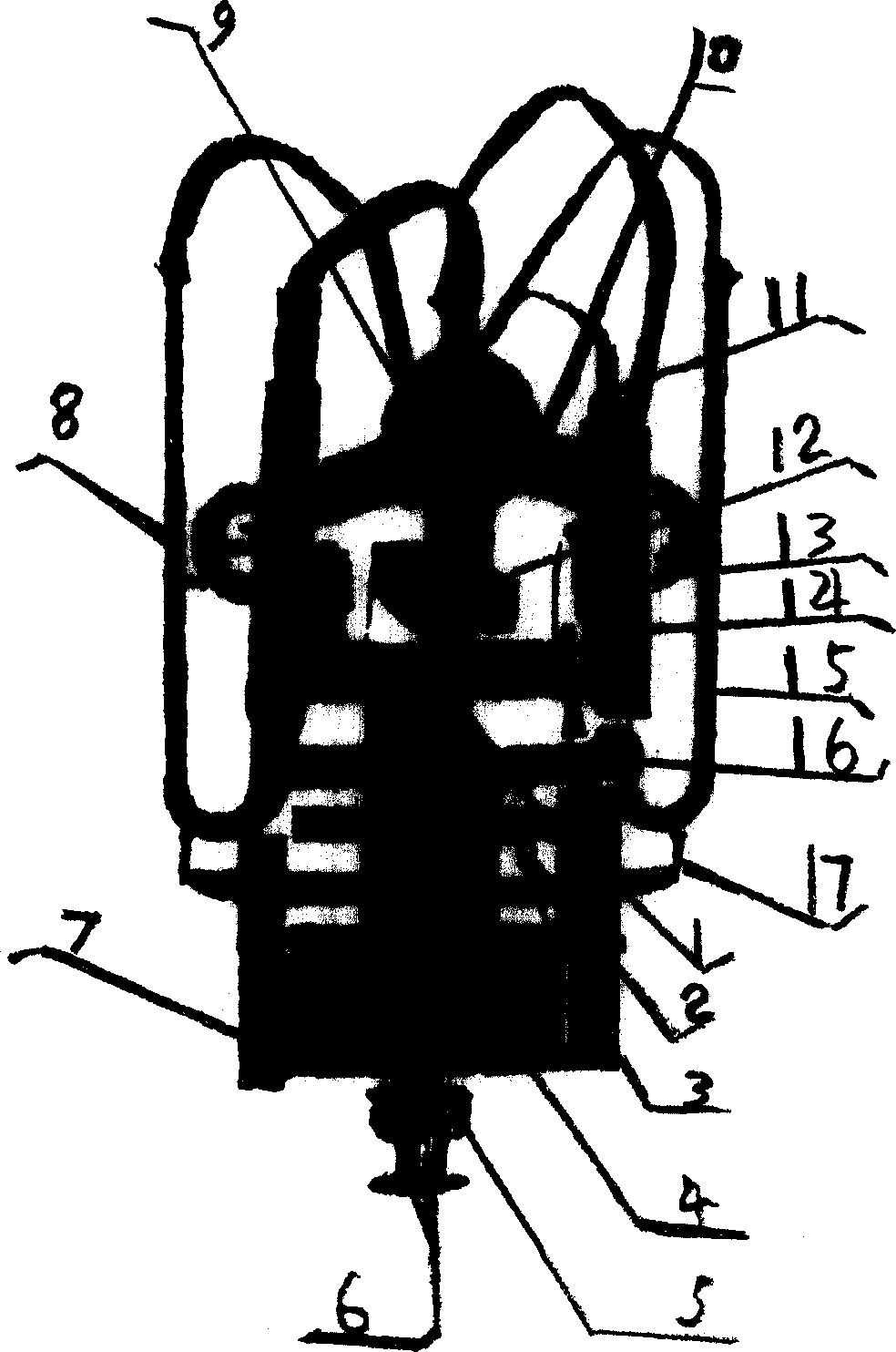

[0011] As shown in the figure, the present invention can capture the exhaust noise of single-cylinder diesel tractors, black smoke, carbon deposits and environmental protection new standard exhaust device, which consists of gas pipe 1, exhaust noise control valve 2, gas guide exhaust pipe 3, and water-gas conversion 4, double guide carbon deposit burner 5, exhaust flange closed air guide pipe 6, carbon deposit purifier 7, flue gas diversion pipe 8, flue gas cooler 9, flue gas convector 10, exhaust air guide hose 11. Flue gas mixer 12, flue gas guide pipe 13, silencing and noise reduction emitter 14, flue gas buffer 15, exhaust hose 16, exhaust water controller 17.

[0012] In the gas guide exhaust pipe 3 of the present invention, double-guided carbon deposit burners 5 are arranged, and the distance between the burners of the carbon deposit burners 5 is gradually arranged from top to bottom. , the top of the gas pipe 1 is equipped with a flue gas convector 10, the side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com