Electronic apparatus having cooling system, radiator thereof, and method for manufacturing thereof

A technology of electronic equipment and heat sink, applied in the field of electronic equipment, can solve the problems of complex manufacturing process, complicated manufacturing process, and manufacturing heat sink, etc., and achieve the effect that the shape is easy to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

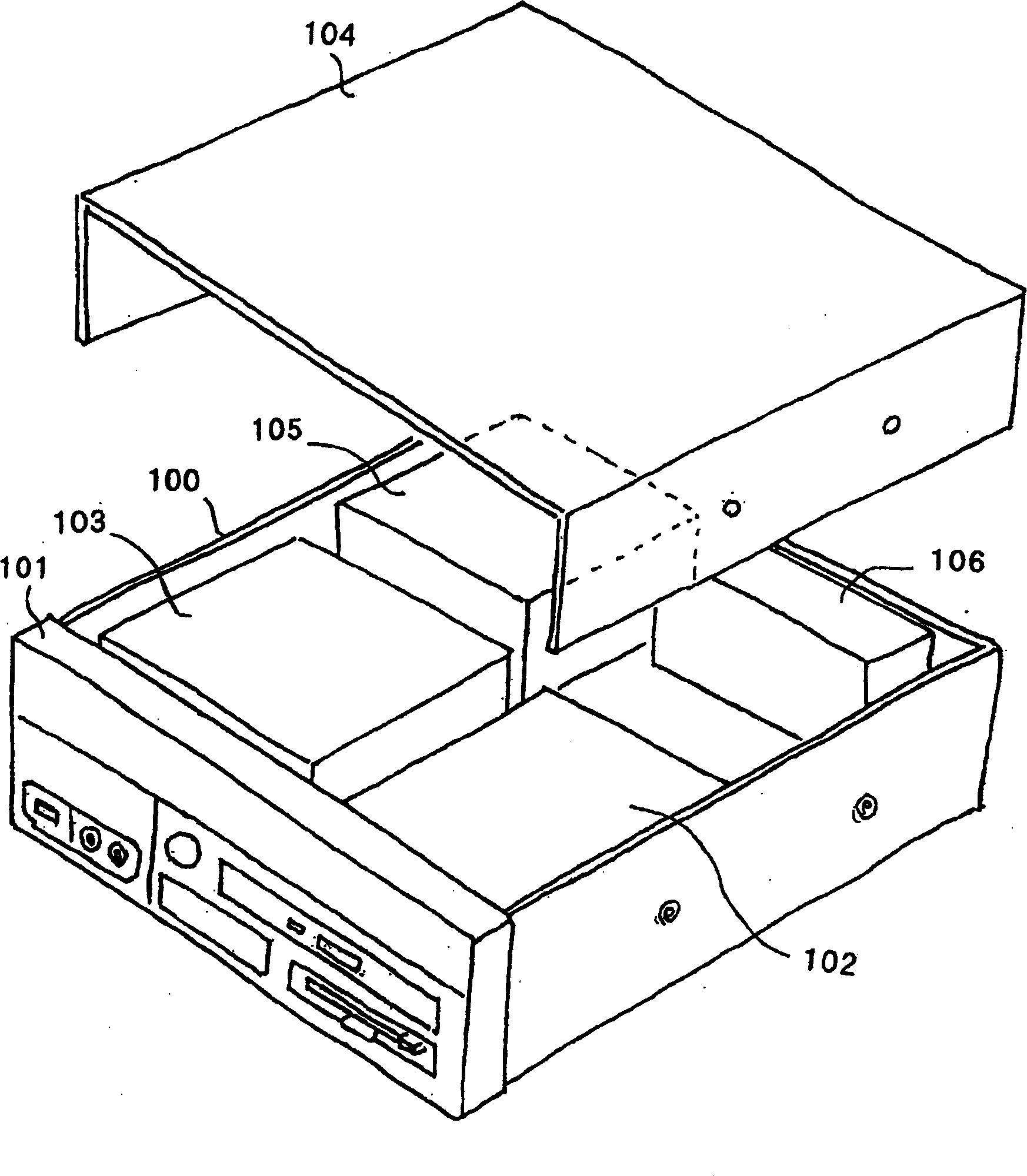

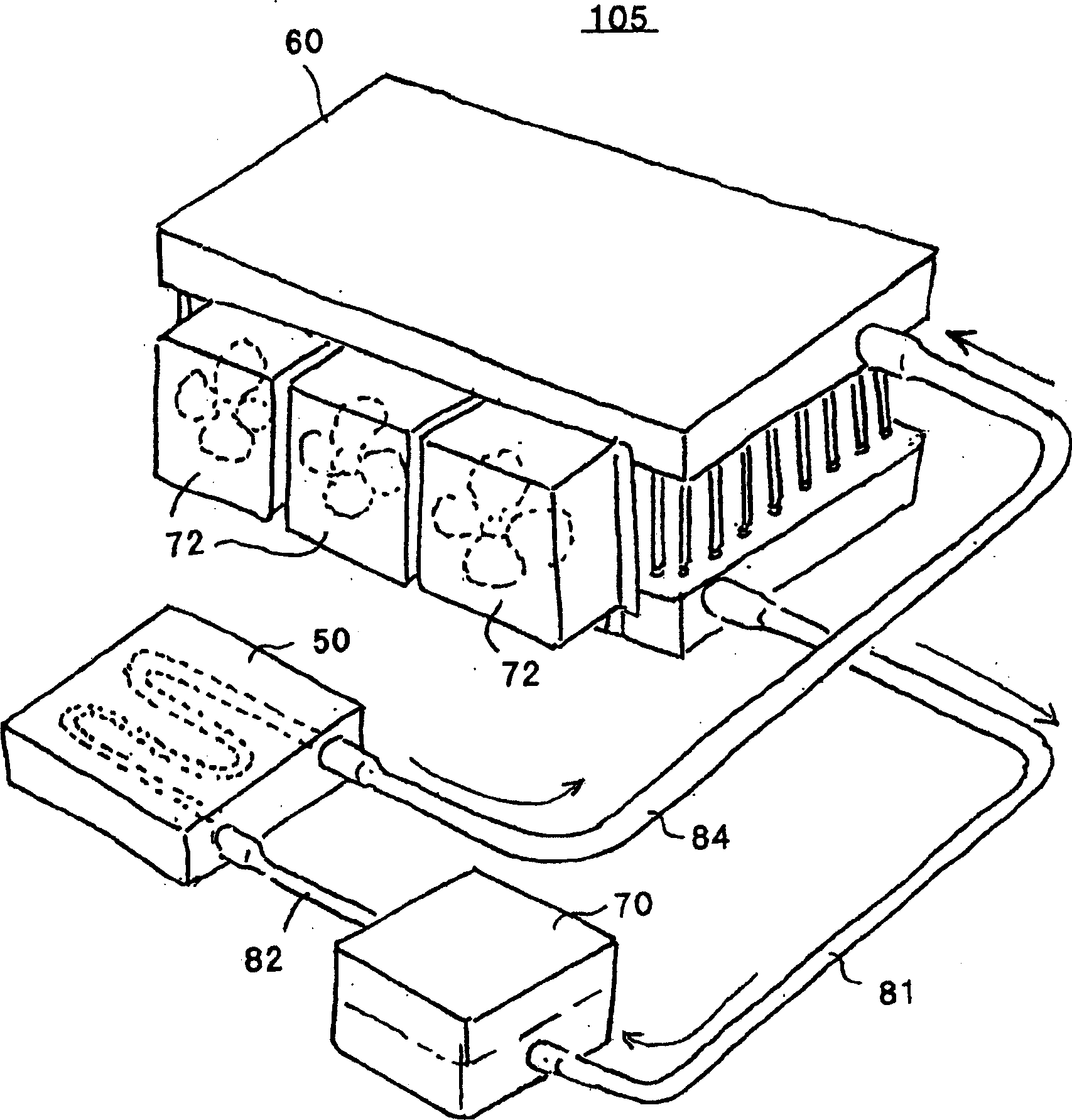

[0023] first, figure 2 An example of the overall configuration of an electronic device having a liquid cooling system according to an embodiment of the present invention is shown. In this example, for example, a case where the present invention is applied to the main body of a desktop personal computer is shown.

[0024] First, as shown in the figure, the main body of a desktop personal computer has a box 100 formed of a metal plate in a cubic shape, for example, and various switches including a power switch, connection terminals, indicator lights, etc. are provided on the front panel 101. , In addition, a drive device 102 for driving various external information recording media such as optical discs, CDs, and DVDs is arranged inside, and is opened toward the above-mentioned front panel portion 101 . In addition, reference numeral 103 in the figure shows a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com