Heat elimination mechanism of electronic equipment

A heat dissipation mechanism and electronic device technology, applied in the direction of elastic/clamping device, circuit arrangement on the support structure, cooling/ventilation/heating transformation, etc., can solve the problems of fan power consumption, poor heat dissipation efficiency, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Some embodiments of the invention are described in detail below. However, the invention may be practiced broadly in other embodiments than those described in detail, and the scope of the invention is not limited except as defined by the appended claims.

[0018] In addition, in order to make the drawings show the features of the invention more concisely and clearly, the related drawings omit some connectors for external signal transmission, and also omit some mechanism parts not related to heat dissipation, and focus on explaining the structure of the heat dissipation mechanism.

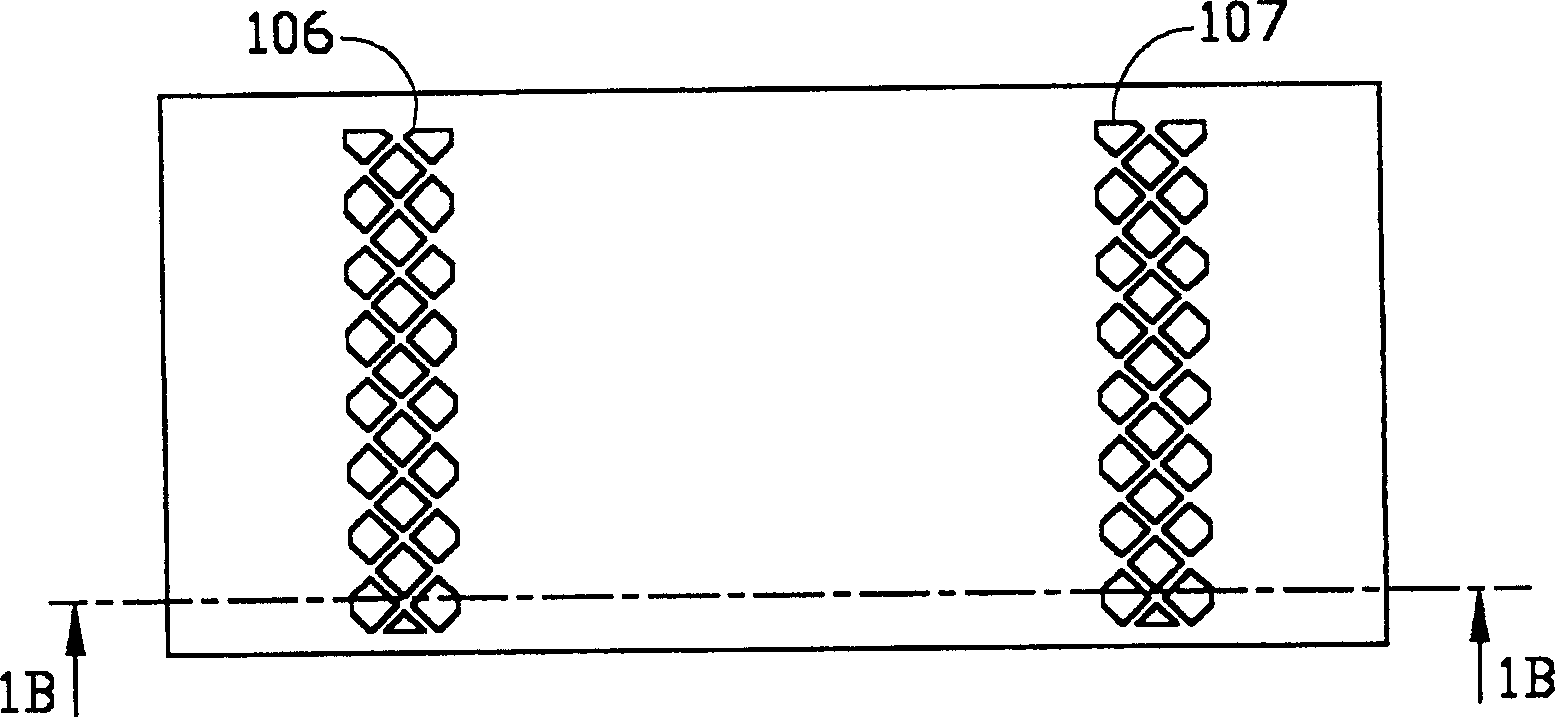

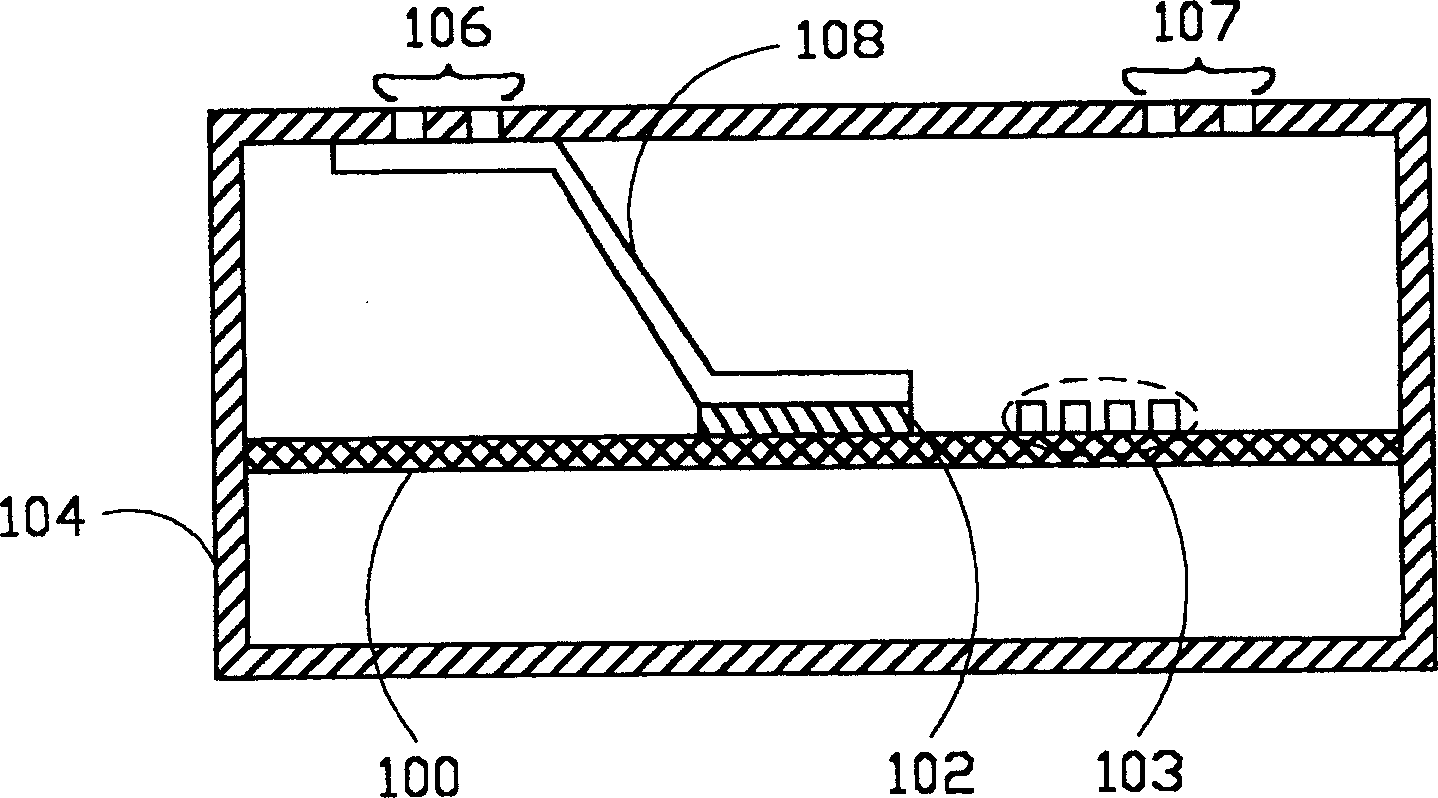

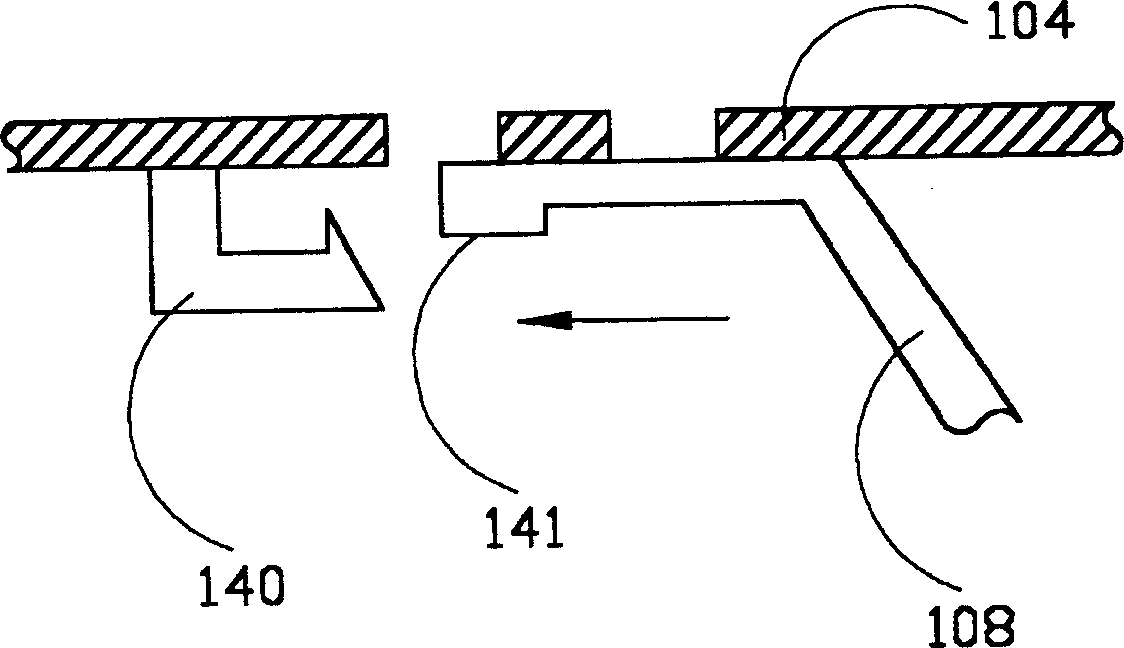

[0019] Figure 1A and Figure 1B It is an external view of a preferred embodiment of the heat dissipation mechanism of the electronic device disclosed in the present invention and a cross-sectional view viewed from the 1B-1B section. At least one heating element 102 is fixed on the substrate 100 , which is the main source of heat generation in the electronic device, and includes other element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com