Method for making wood floor by pure poplar

A technology of solid wood flooring and crafting methods, which is applied to the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problems of wasting hard wood resources, feeling uncomfortable, and high prices, so as to increase utilization channels and reduce The effect of consumption and natural color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

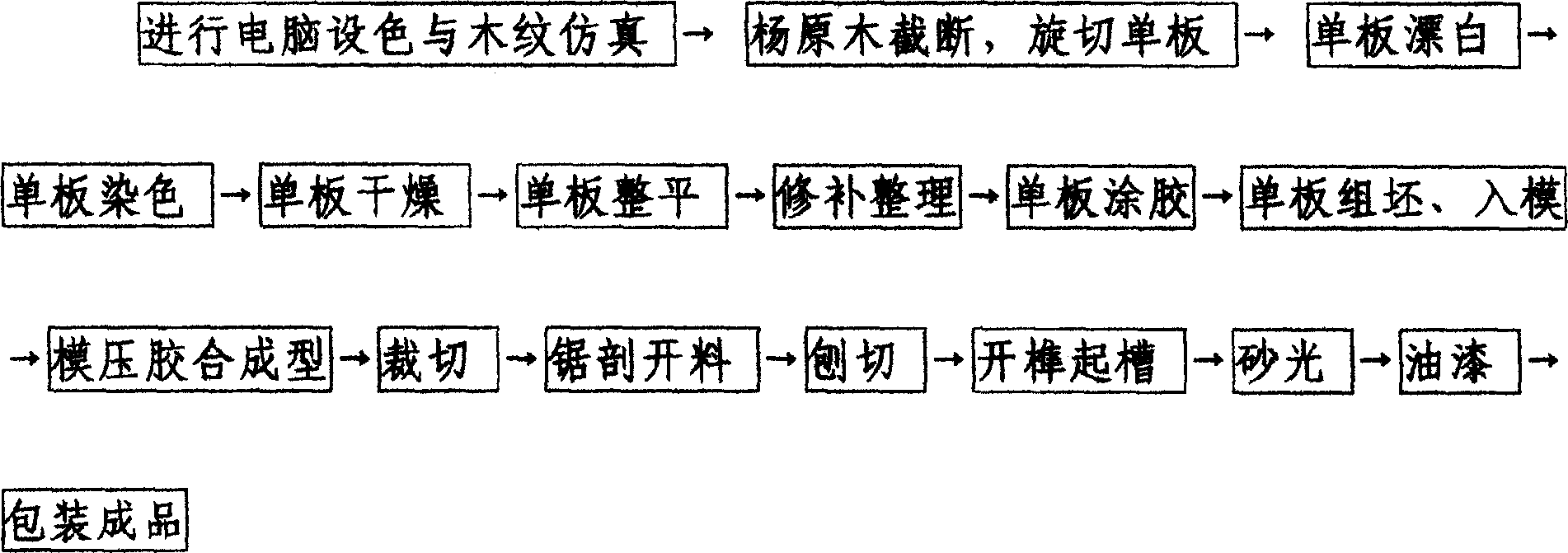

[0007] This invention utilizes pure poplar wood to make the technological method of solid wood floor, is to realize through following steps:

[0008] (1) Carry out computer color setting and wood grain simulation: a, database establishment: select various hard woods that are commonly used in the manufacture of floors, and are representative in color and texture, collect them with digital photography, and then input them into the computer , establish standard wood color and texture database; b, dyeing solution preparation: use common dyes and different concentrations to prepare dyeing solution, carry out small test of wood dyeing, and compare with standard database to form a fixed formula of dyeing solution; c, mold design : According to the texture database, use 3D CAD technology to design different molds for wood grain simulation processing;

[0009] (2) Poplar logs are cut off and cut into veneers: general wood processing machinery can be used. The size of the veneer is gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com