Compact high power LED array

A LED array, high-power technology, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve problems such as redundancy, difficulty in removing fan noise, gap between shockproof performance and working stability, etc. The effect of uniform distribution, small lateral thermal resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

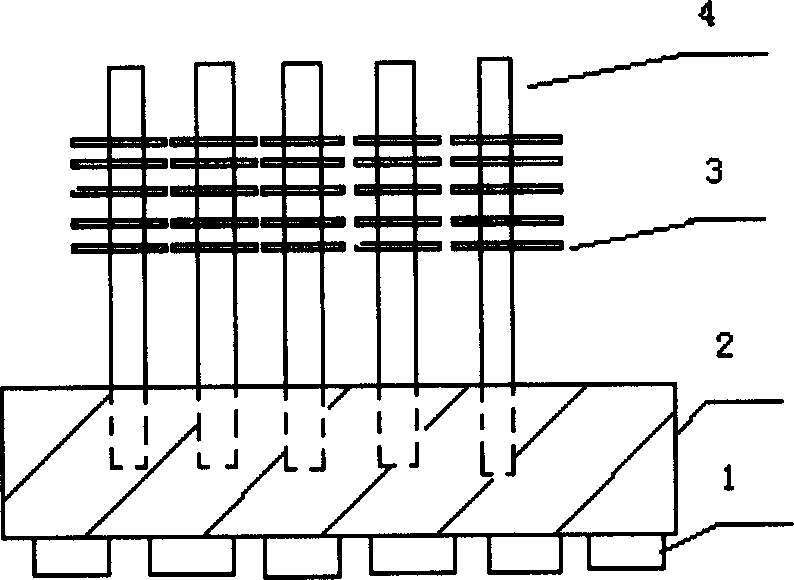

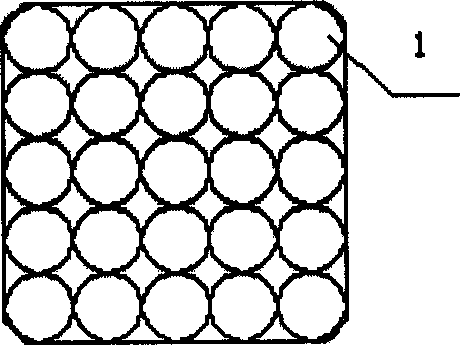

[0028] Embodiment 1 adopts a gravity heat pipe. from figure 1 It can be seen that the system consists of four parts. For the present invention, the extensibility of the heat sink and the bottom plate is conducive to the close contact with the heat pipe, so aluminum is used to make the device.

[0029] First, align the bottom plate and heat sink plate, and drill holes in the corresponding positions of bottom plate 2 and heat sink plate 3. The holes on the bottom plate are not opened through, and the hole depth is about half of the thickness of the bottom plate. Drill and tap screw holes on the lower surface of the bottom plate. Insert the heat pipe into the heat sink and solder the contacts together. Fix the LED 1 on the lower surface of the bottom plate. Insert the heat pipe with heat sink at one end into the hole on the upper surface of the LED base plate and solder them together.

[0030] Figure 4 It is a side view of the second embodiment of the present invention

Embodiment approach 2

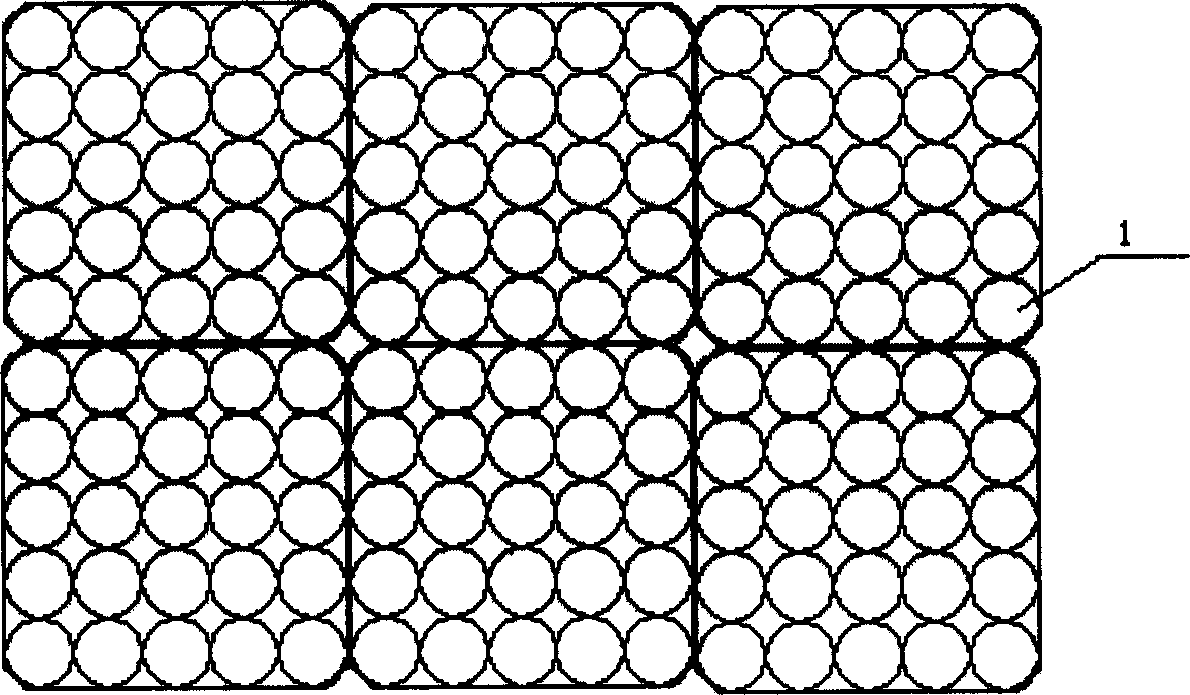

[0031] The posture of the heat pipe in Embodiment 2 is different from that in Embodiment 1. First bend the heat pipe to a certain angle. Drill holes horizontally on the bottom plate. Drill holes on the heat sink, the same as method 1. The assembly process is also the same as in method 1, as shown in the figure. Compared with method 1, method 2 has a better heat dissipation effect, because the contact between the bottom plate and the heat pipe is more sufficient. However, the disadvantage of the second method is that the two-dimensional splicing is not convenient, and it is more suitable for strip light sources.

[0032] The number of heat sinks in the two schemes is the same. For a LED of about 100W, the effective area of the heat sink is 3000cm2, and it can work normally under natural cooling. The whole lamp provides a luminous flux of about 2000lm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com