Water-fire compatible water heater

A hot water machine, water fire technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of bulky hot water equipment, complex structure, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

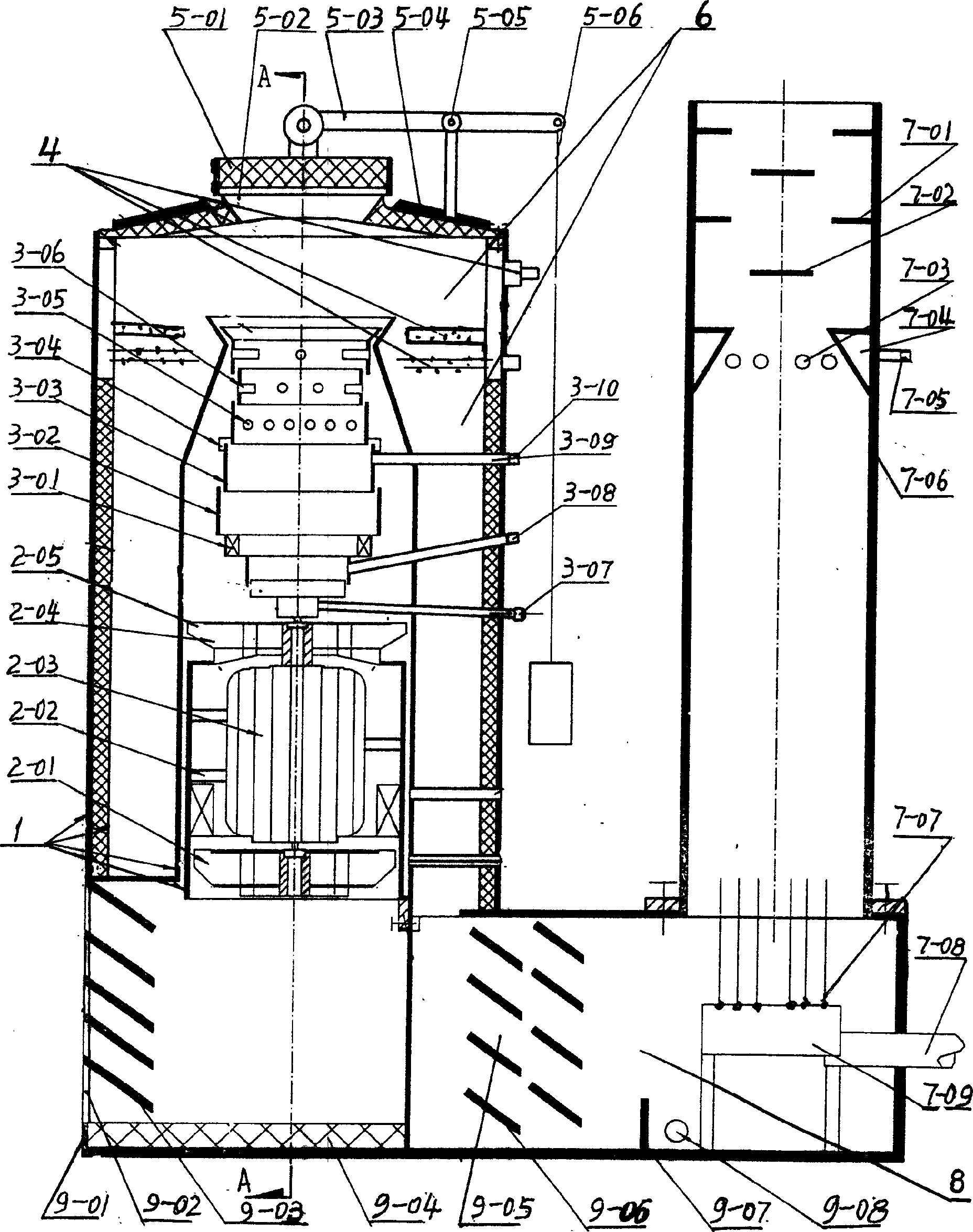

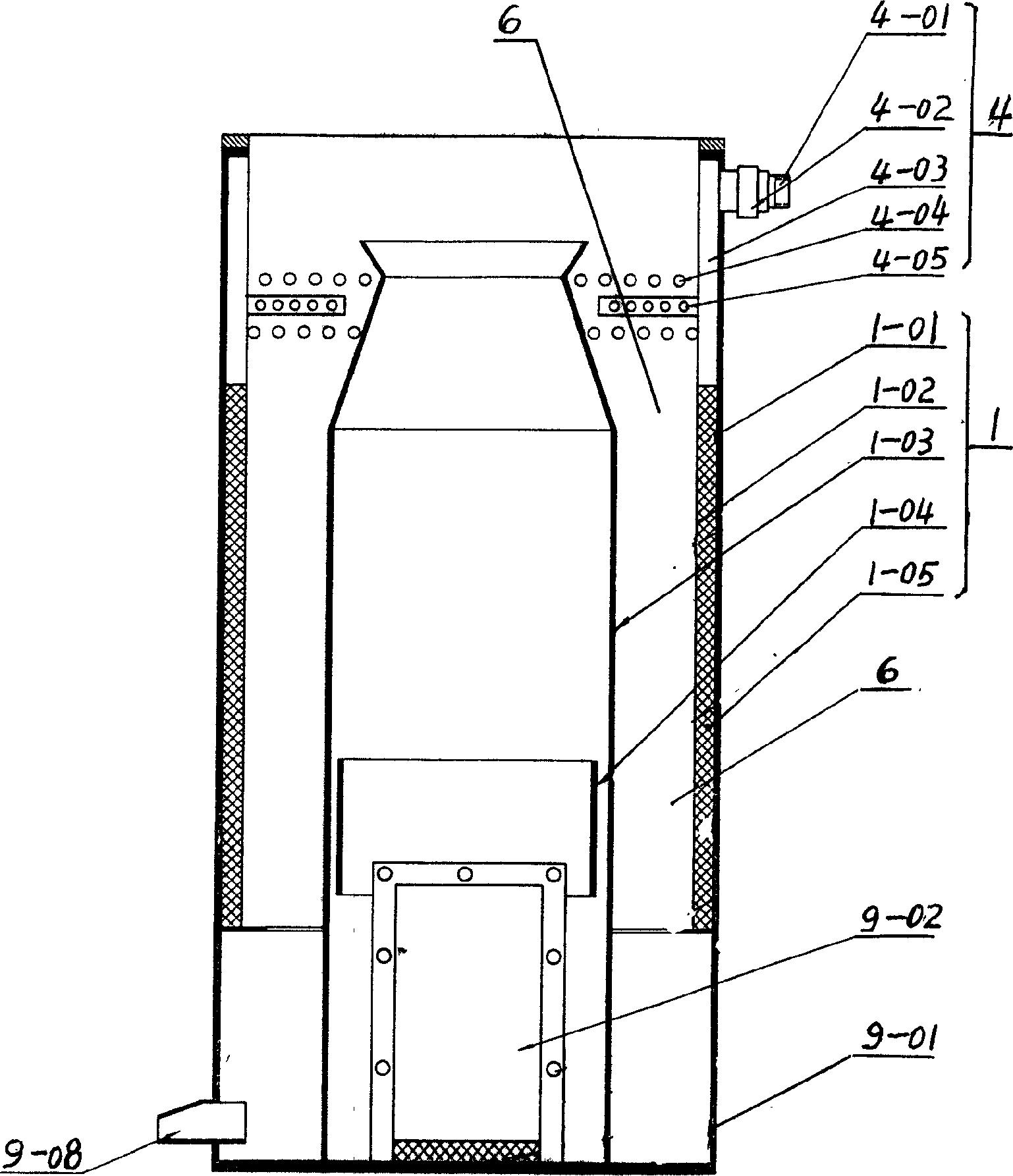

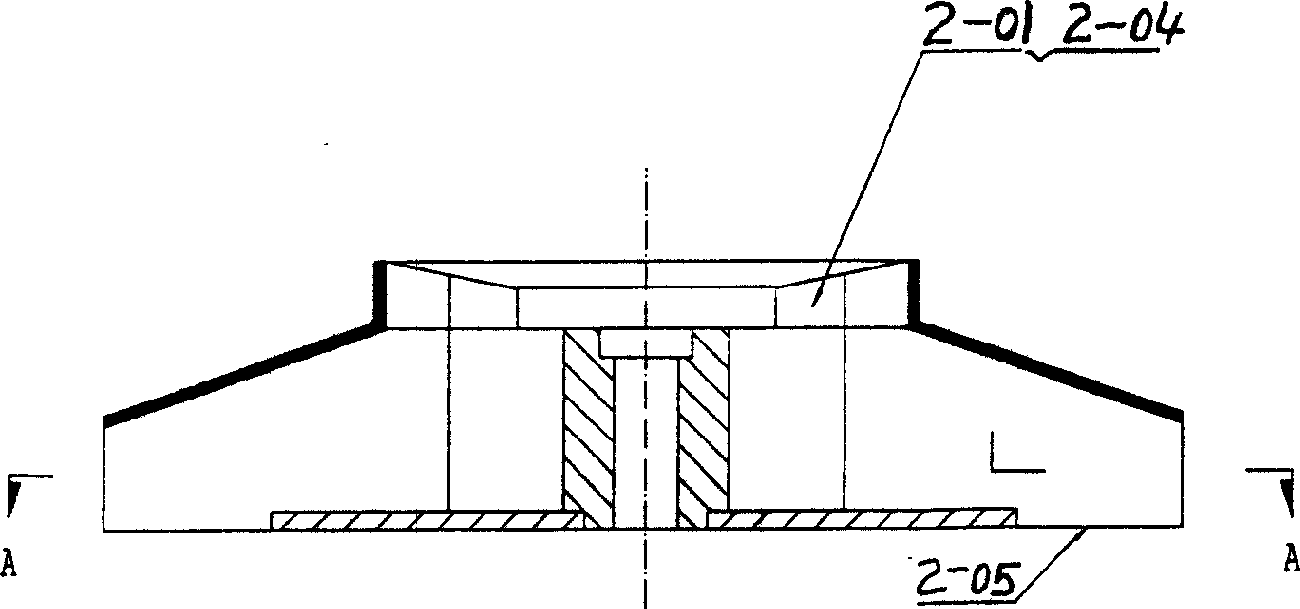

[0018] A water and fire compatible water heater, which mainly includes a casing, a fan, a burner, an atomizing water spray device, a heat exchange chamber, a base reservoir and an exhaust pipe, see the attached figure 1 , the casing 1 is a double-layer cylindrical casing with an inner and outer casing vertically installed on the base 9, a hot air reflection top cover 5 is arranged on the upper end of the outer casing 1, and the top cover is spaced apart from the upper end of the inner casing, and the inner casing is separated from the outer casing and Between the top covers is a water and fire compatible heat exchange chamber 6, and the atomizing water spray device 4 is arranged in the heat exchange chamber outside the upper end of the inner shell. The right end of 9 is a hot water storage tank 8, which is connected to the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com