Wiring structure

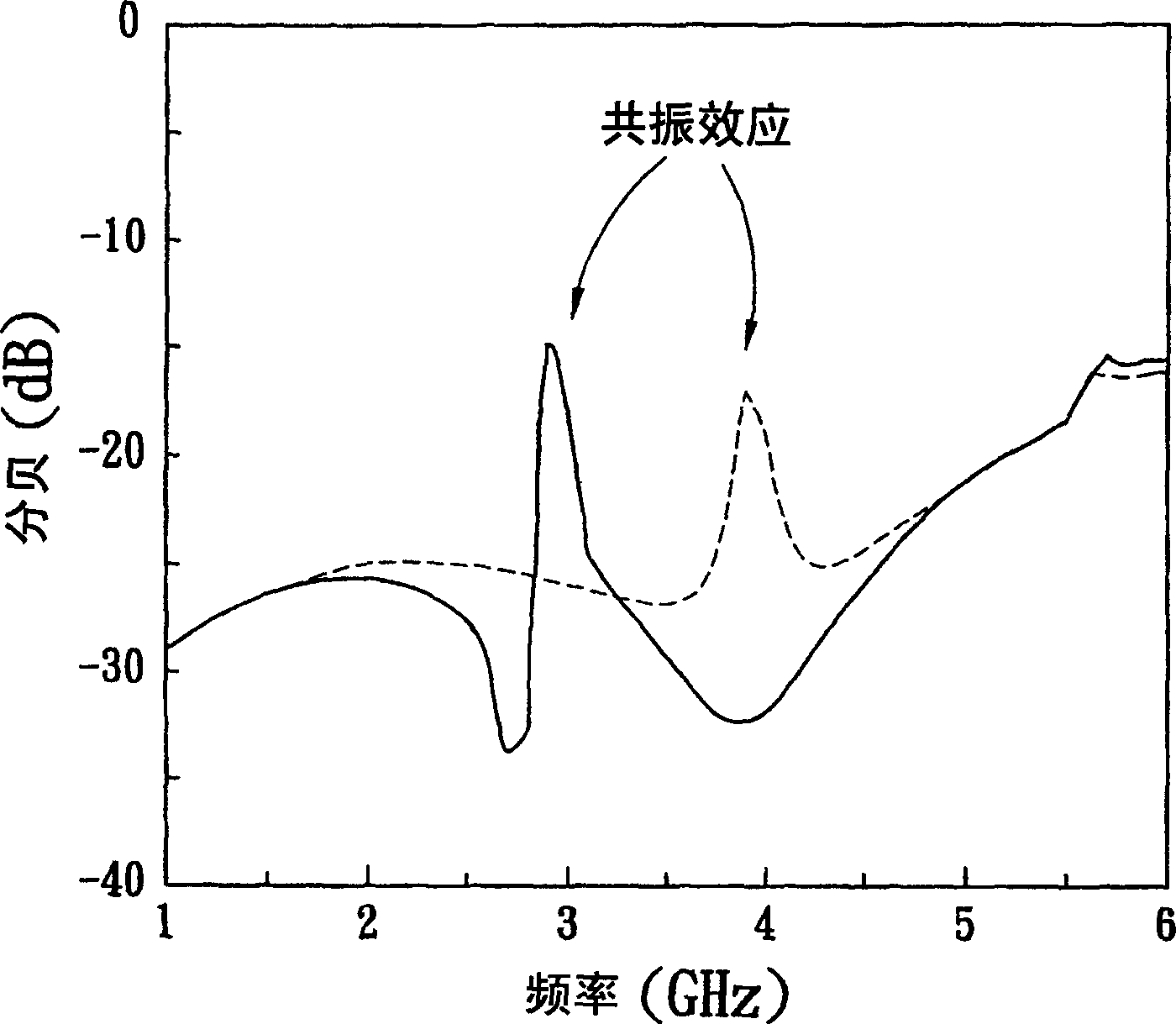

A wiring structure and wiring technology, applied in the direction of multilayer circuit manufacturing, printed circuit components, etc., can solve the problems of circuit board damage resonance, severe resonance effect parasitic oscillation of circuit board, circuit structure quality degradation, etc., to increase circuit quality, Overcoming the effects of time design, reducing resonance effects and parasitic oscillations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

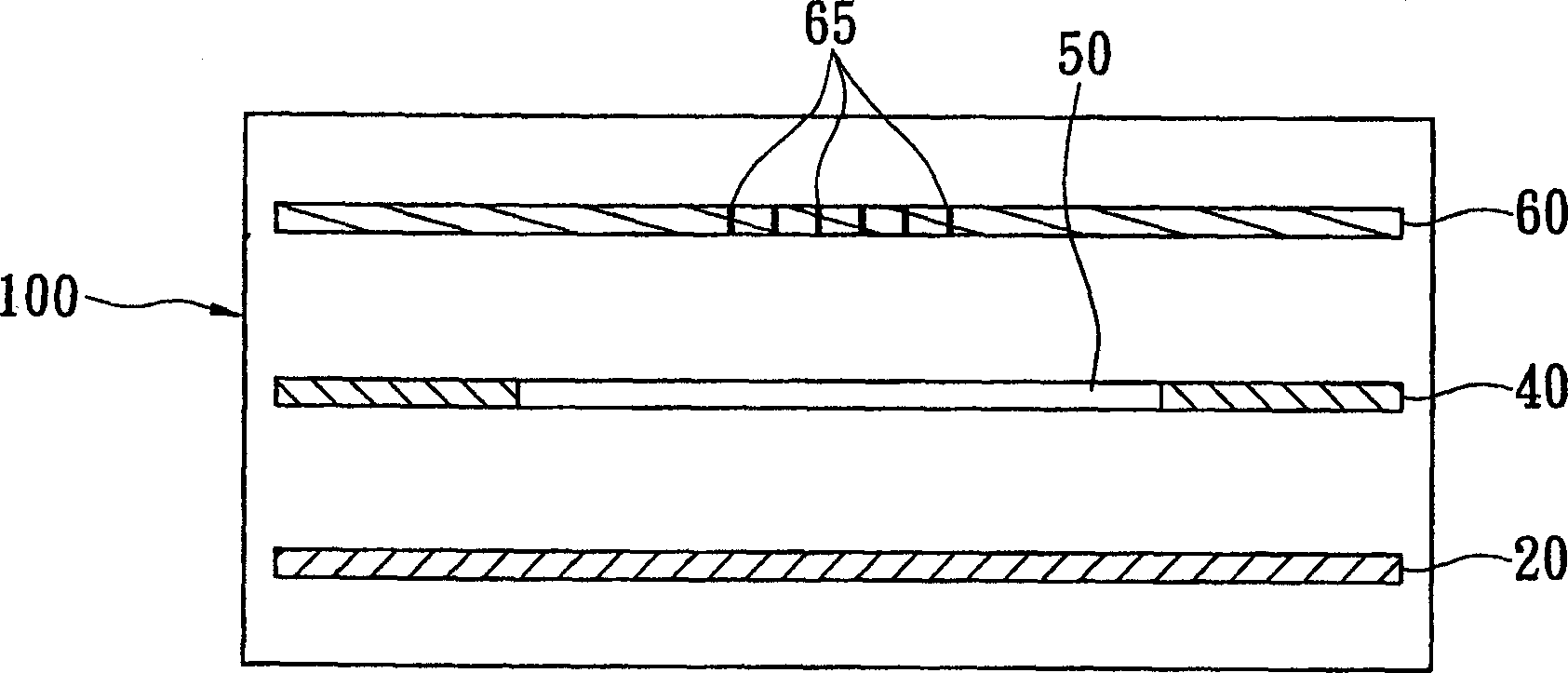

[0027] The main purpose of the present invention is to provide a wiring structure that improves the wiring response, thereby eliminating the poor coupling between the layers of the circuit board and improving the wiring response. First see image 3 A schematic side view of the inner cloth structure of the printed circuit board of the present invention, which shows the inside of the circuit board 100 of a multilayer board, including a ground plane 20, a power plane 40, and a wiring plane 60. However, in practical applications, It may further include various planes (not shown in this figure) such as a component plane, an insulating plane, a dielectric plane, and a signal plane, which are not limited by this embodiment.

[0028] On the wiring plane 60, a plurality of wiring lines 65 are provided to connect the signal transmission between the planes. And a power plane 40 is further provided above or below the wiring plane 60 (in this embodiment, the power plane 40 is located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com