Combine

A technology for combine harvesters and harvesting departments, which is applied to the chassis of harvesters, cutters, and agricultural machinery, etc. It can solve problems such as the difficulty of hanging and removing drive belts, and achieve the effect of improving maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

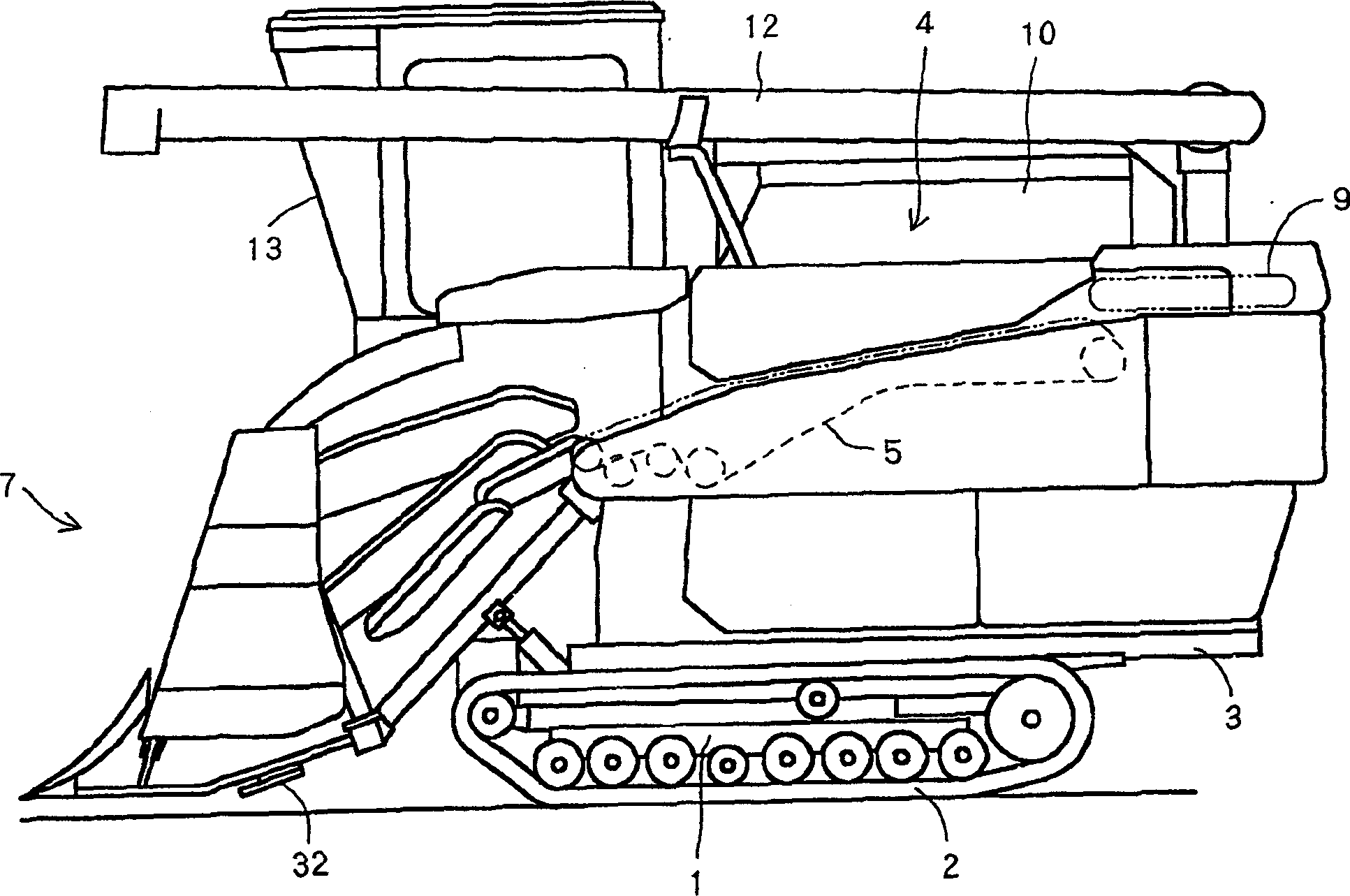

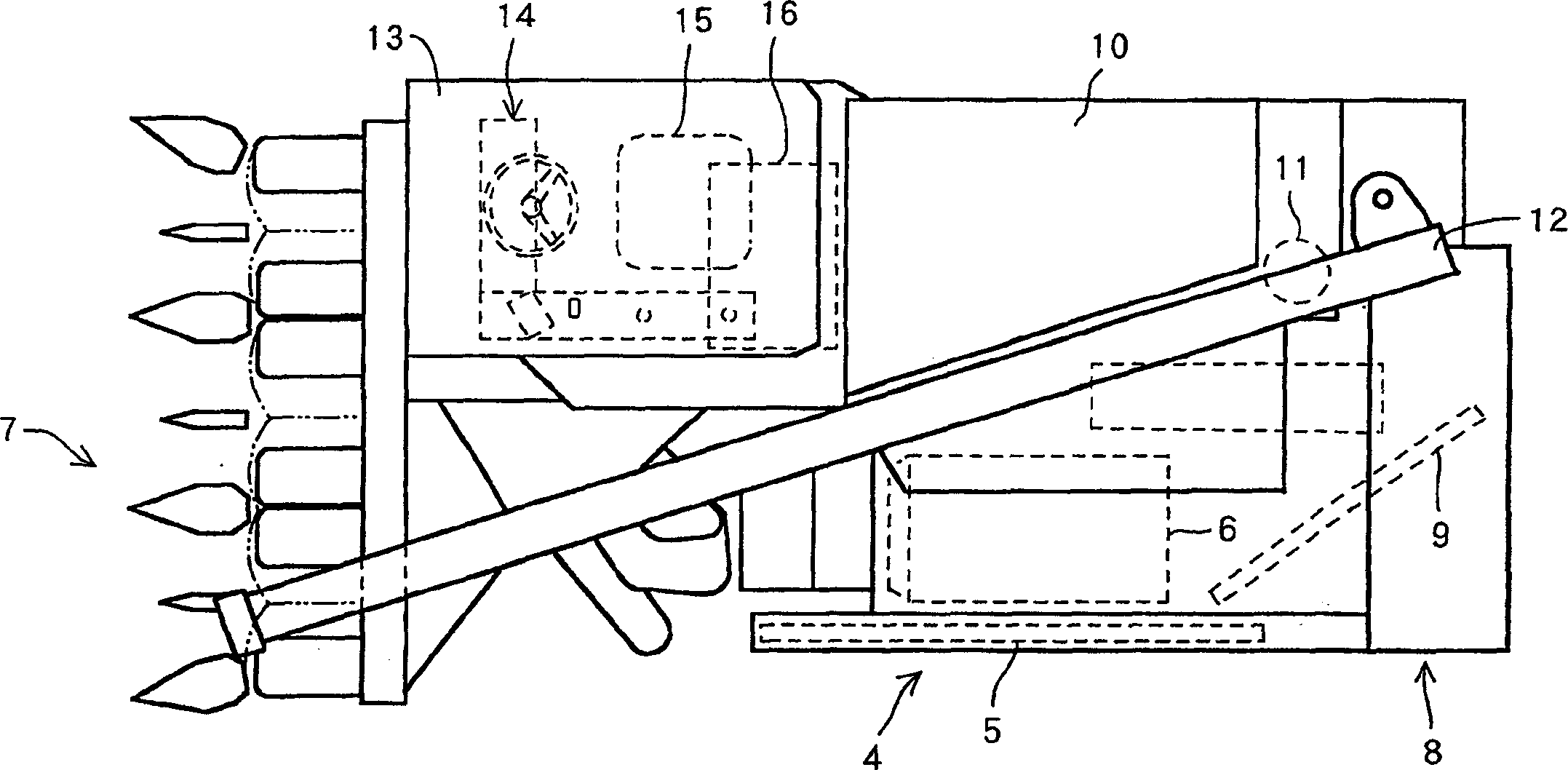

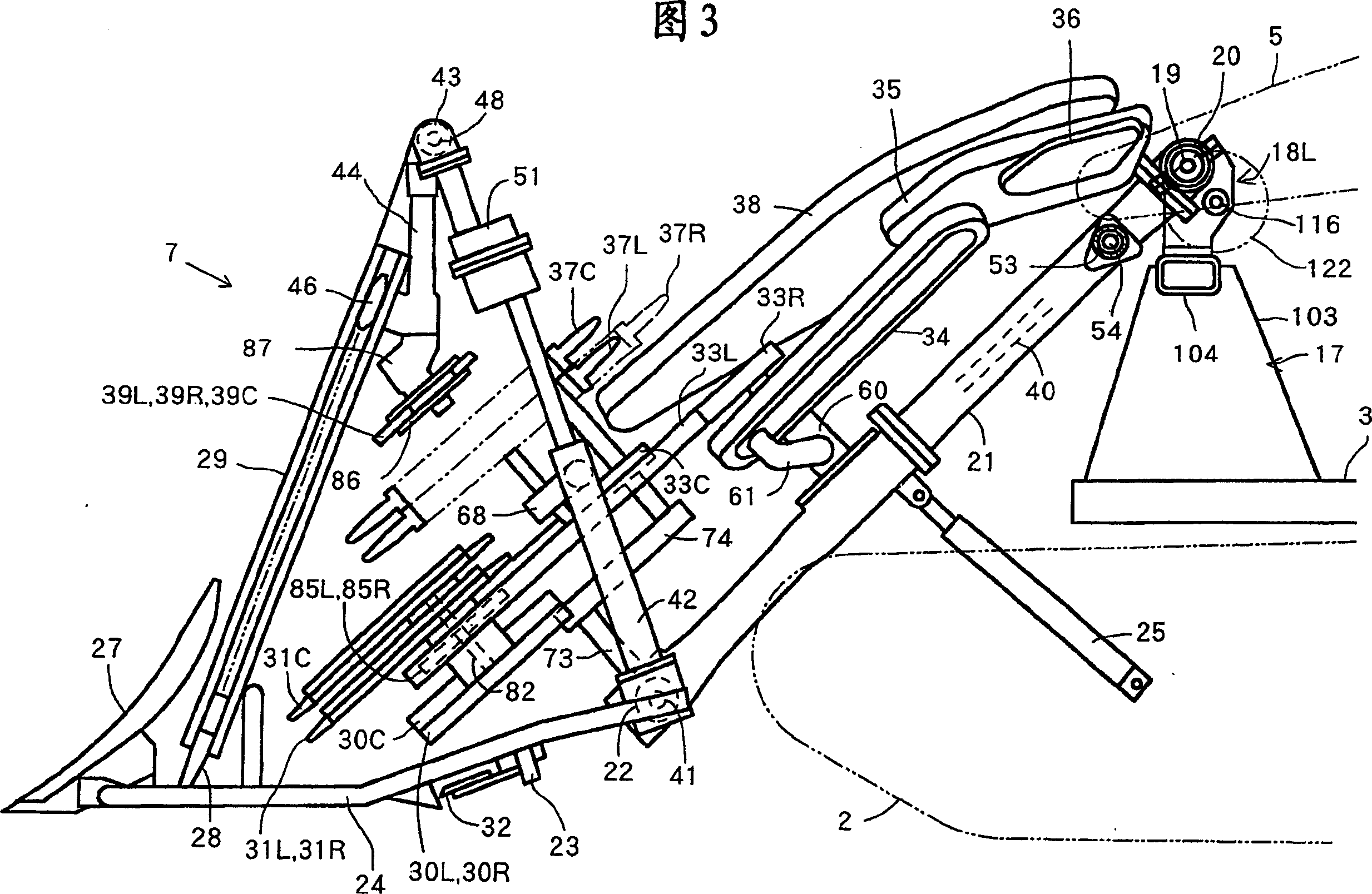

[0037] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 is the overall side view of the combine harvester, figure 2 Is the overall top view of the combine harvester, in the figure 1 is the bogie frame with left and right running crawlers 2 installed, 3 is the vehicle frame erected on the bogie frame 1, 4 is the feed chain 5 is set on the left side, and the inner The threshing part that handles barrel 6 is hidden, and 7 is the harvesting part of the 6 ridges that have in the place ahead of above-mentioned threshing part 4, and 8 is the straw discharge processing part near the terminal of the straw chain 9, and 10 is through the grain raising tube 11 , the grain box that carries the grains from the threshing unit 4, 12 is a discharge screw conveyor that discharges the grains in the grain box 10 out of the machine, and 13 is a cockpit with an operation operation unit 14 such as a steering handle and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com