Apparatus for machining coated plastic door and window section bar

A plastic door, window and wrapping technology, applied in the field of plastic processing machinery, can solve the problems of increased production cost, complex mold structure, difficult debugging, etc., and achieve the effect of improving production efficiency, simplifying process and reducing processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

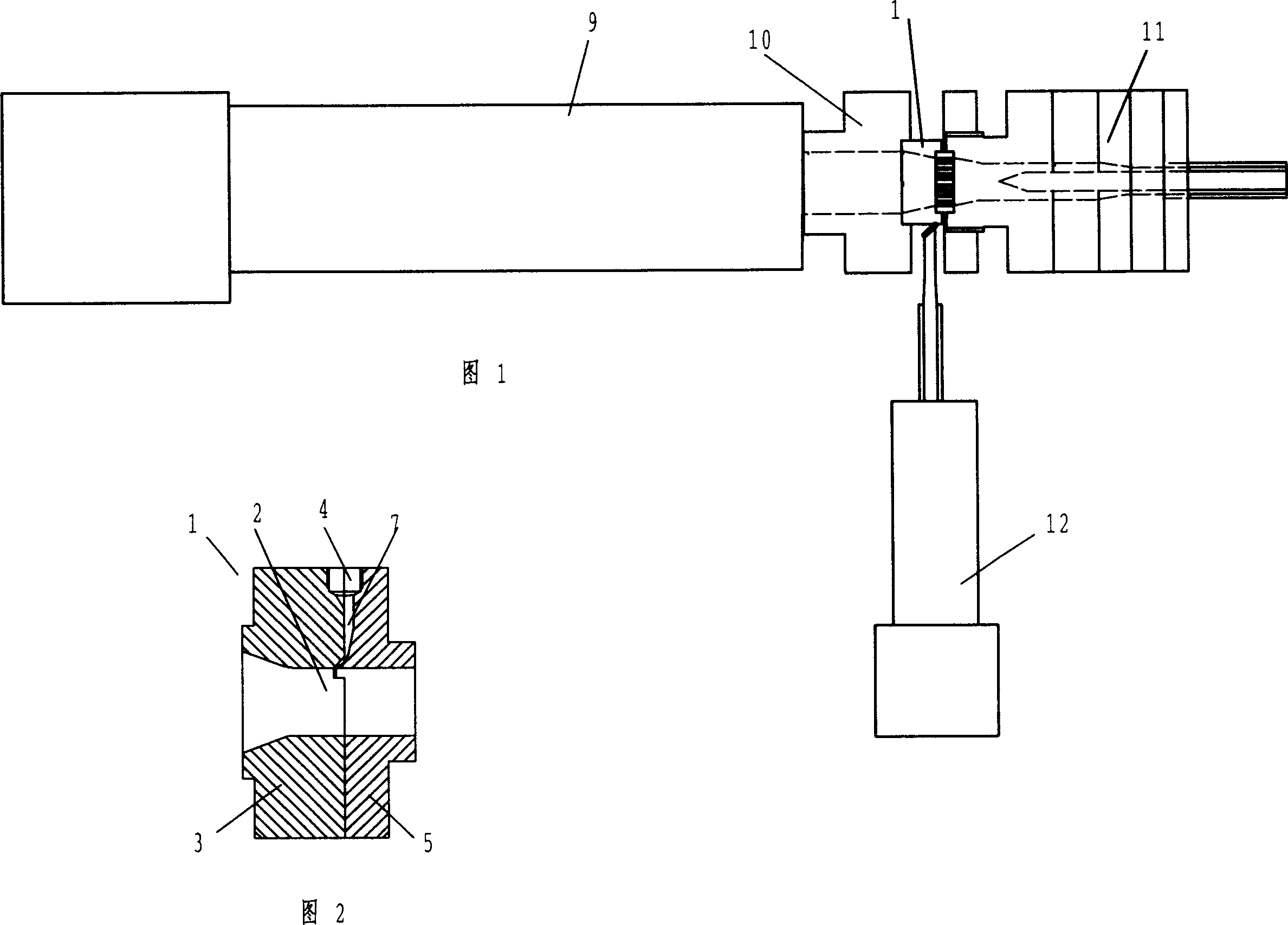

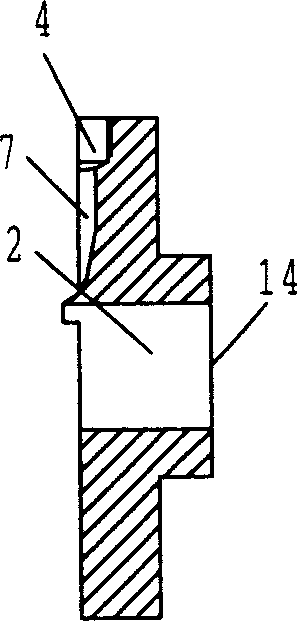

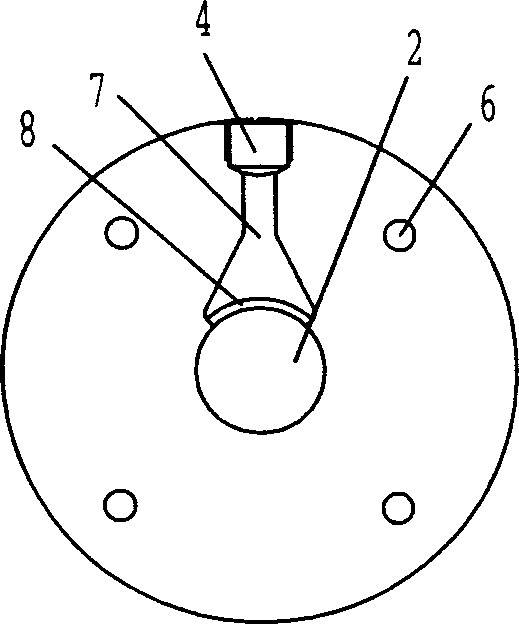

[0021] The present invention is used to produce the special-purpose device of coated plastic door and window profile, referring to Fig. A connecting sleeve 1 is provided between the extruder cylinder 10 and the core material die head 11 . Referring to Figure 2, the core material main channel 2 is arranged axially on the connecting sleeve, the left end of the core material main channel communicates with the barrel of the core material extruder; Decreasing, or as shown in Figure 9, the inner diameter is a variable diameter whose middle size is smaller than the two ends. The above structure is convenient for use with extruders of different specifications. A connecting port 4 of the surface material co-extrusion machine is provided along the radial direction of the connecting sleeve.

[0022] See Figure 2, image 3 , Figure 7 , The connecting sleeve is made of left and right half connecting sleeves 3, 5, the left and right half connecting sleeves are processed respectively, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com