Composite thermosetting film for inflated spatial expanded structure and its making and rigidizing process

A technology of composite film and space inflation, which is applied in the direction of layered products, etc., and can solve problems such as being in the confidentiality stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

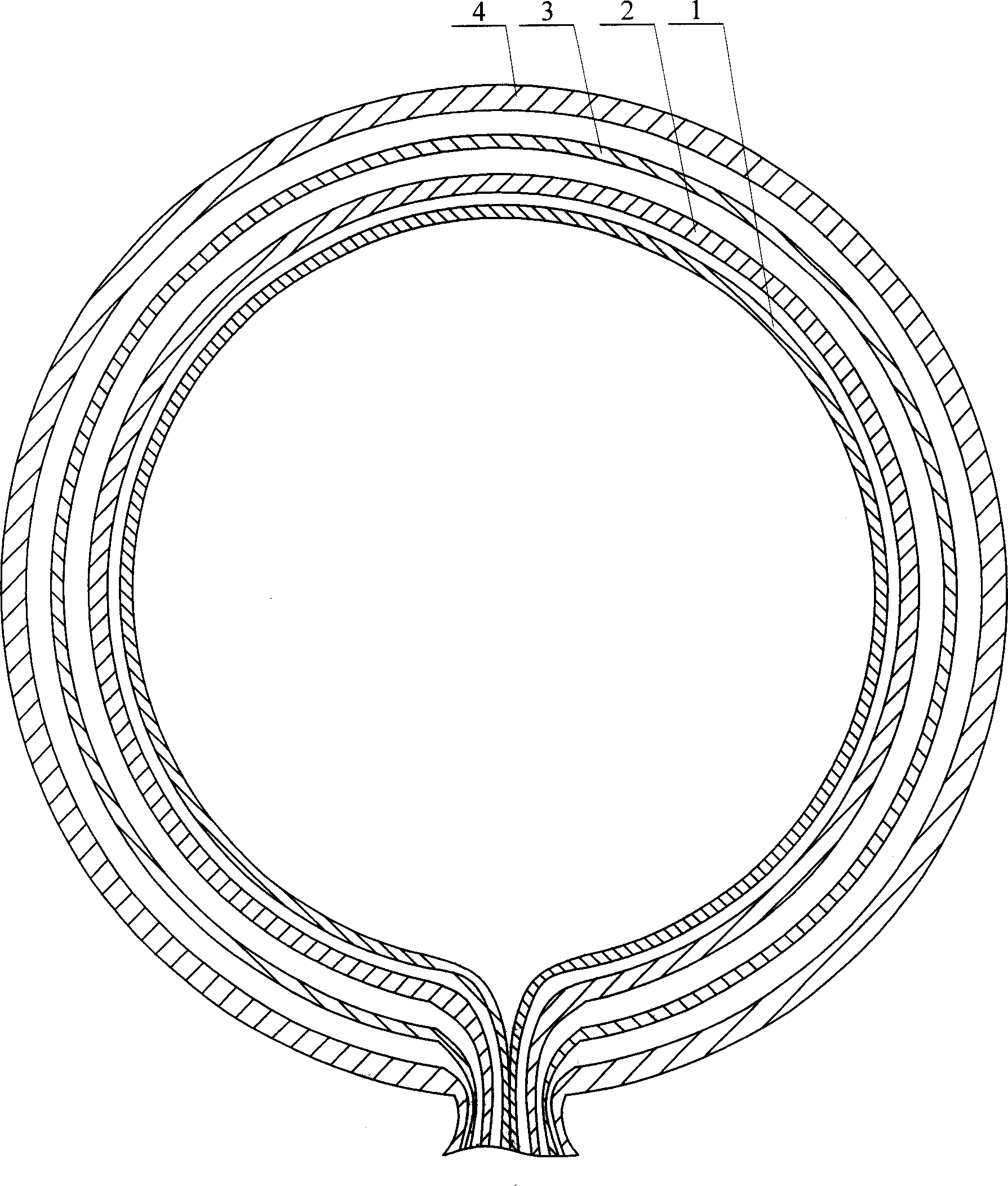

[0005] Specific implementation mode one: (see figure 1 ) The thermosetting composite film of this embodiment is composed of an internal gas barrier layer 1, a stiffening layer 2, a heating layer 3, and an external heat insulating layer 4; the stiffening layer 2 is arranged on the outside of the inner gas barrier layer 1, and the heating layer 3 is arranged on Outside the stiffening layer 2 , an external thermal insulation layer 4 is arranged outside the heating layer 3 . The thickness of the inner gas barrier layer 1 is 0.025mm-0.05mm; the thickness of the rigid layer 2 is 0.1-0.8mm; the thickness of the heating layer 3 is 0.1-0.3mm; the thickness of the outer heat insulation layer 4 is 0.5-1mm. The method of making and stiffening the thermosetting composite film in this embodiment is as follows: 1. The making of the internal gas barrier layer 1: make the polyimide film or the polyester film into a spherical, cylindrical or tubular shape (the shape after inflation and expansio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com