Liquid crystal display panel

A liquid crystal display panel and liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor display characteristics of liquid crystal display panels, and achieve the effects of good display characteristics, avoiding direct contact, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

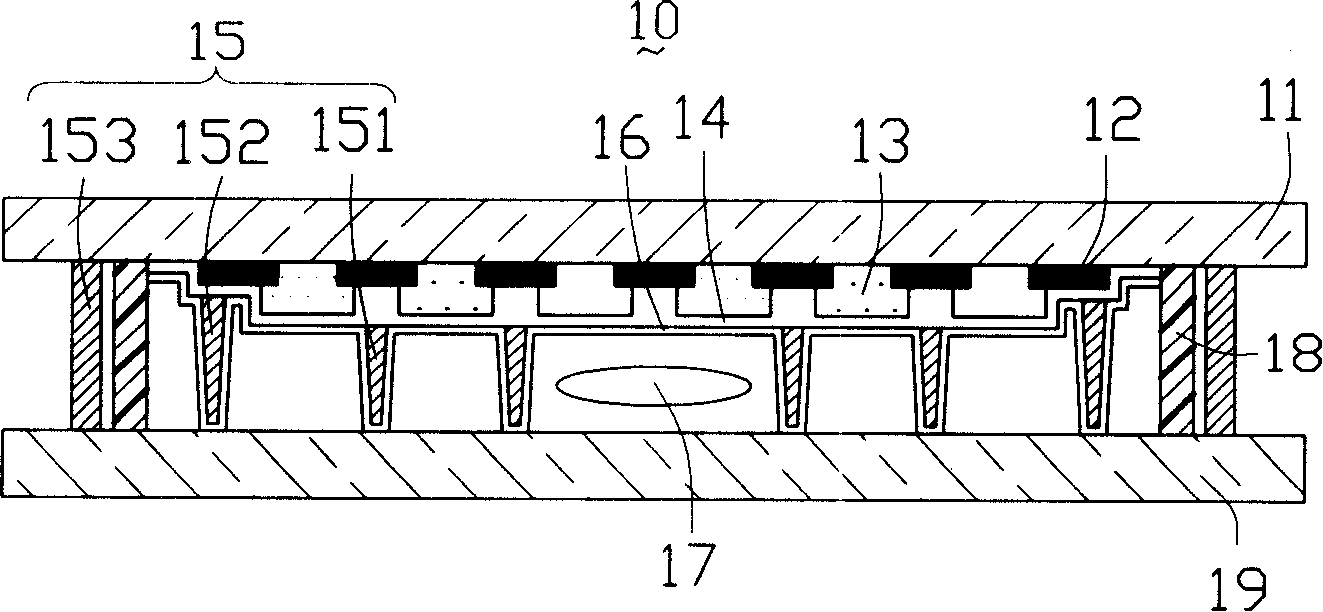

[0024] Such as image 3 Shown is a schematic cross-sectional view of the first embodiment of the liquid crystal display panel of the present invention. The liquid crystal display panel 10 includes a first substrate 11 , a second substrate 19 and a sealant 18 , wherein the first substrate 11 and the second substrate 19 are disposed opposite to each other, and a liquid crystal layer 17 is disposed therebetween. The sealant 18 is disposed between the first substrate 11 and the second substrate 19 , tightly adheres the first substrate 11 and the second substrate 19 , and forms a closed space. The frame glue 18 surrounds the liquid crystal display panel 10 to block the liquid crystal molecules from the outside world and frame the closed space between the first substrate 11 and the second substrate 19. The frame glue 18 can be made of acrylic resin or epoxy resin. Mixtures are made of materials.

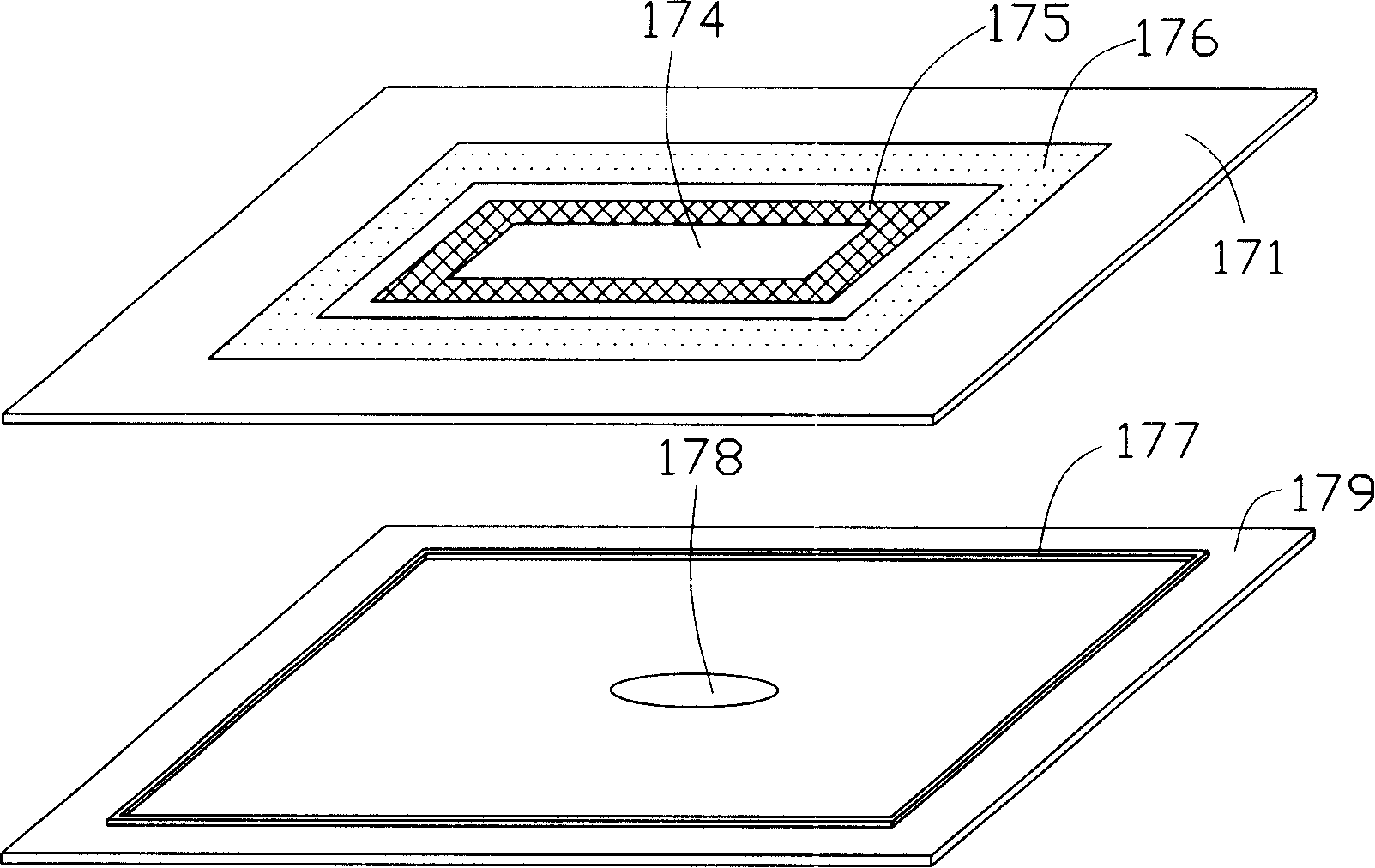

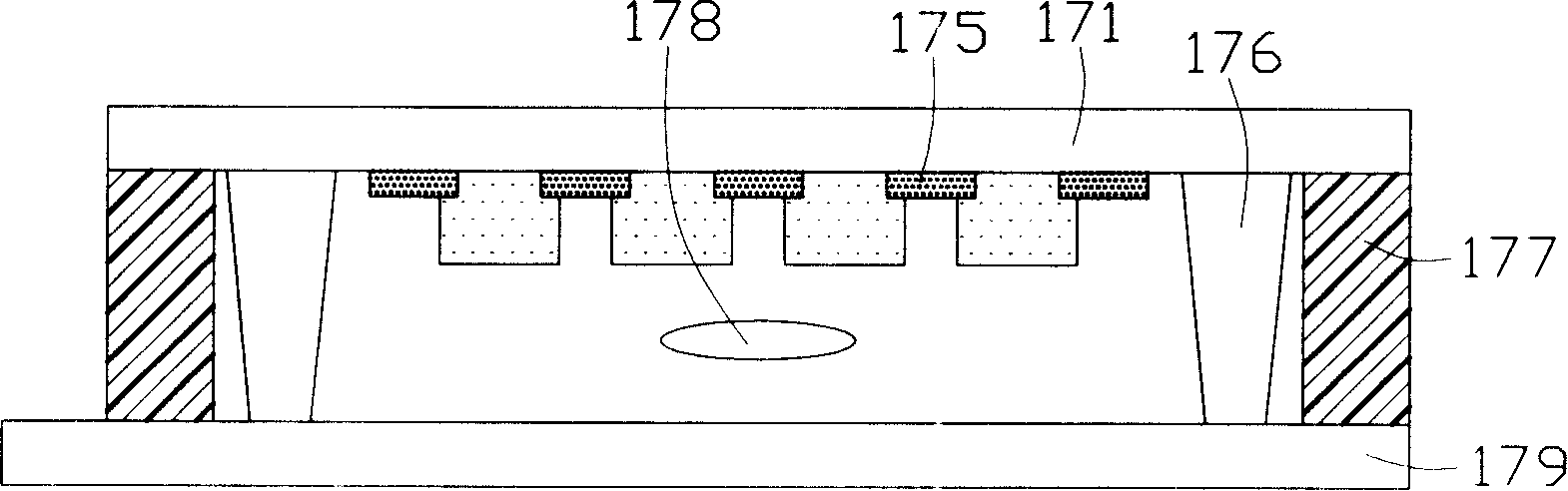

[0025] Please also refer to Figure 4 , is a schematic plan view of the first subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com