Moulding for special transformer double-spiral winding and winding method

A special transformer and winding method technology, applied in the field of transformer manufacturing, can solve the problems of hidden danger of transformer operation, inability to guarantee mechanical strength and short-circuit resistance, and large springback, so as to ensure the normal operation quality and improve the ability to withstand short-circuit. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

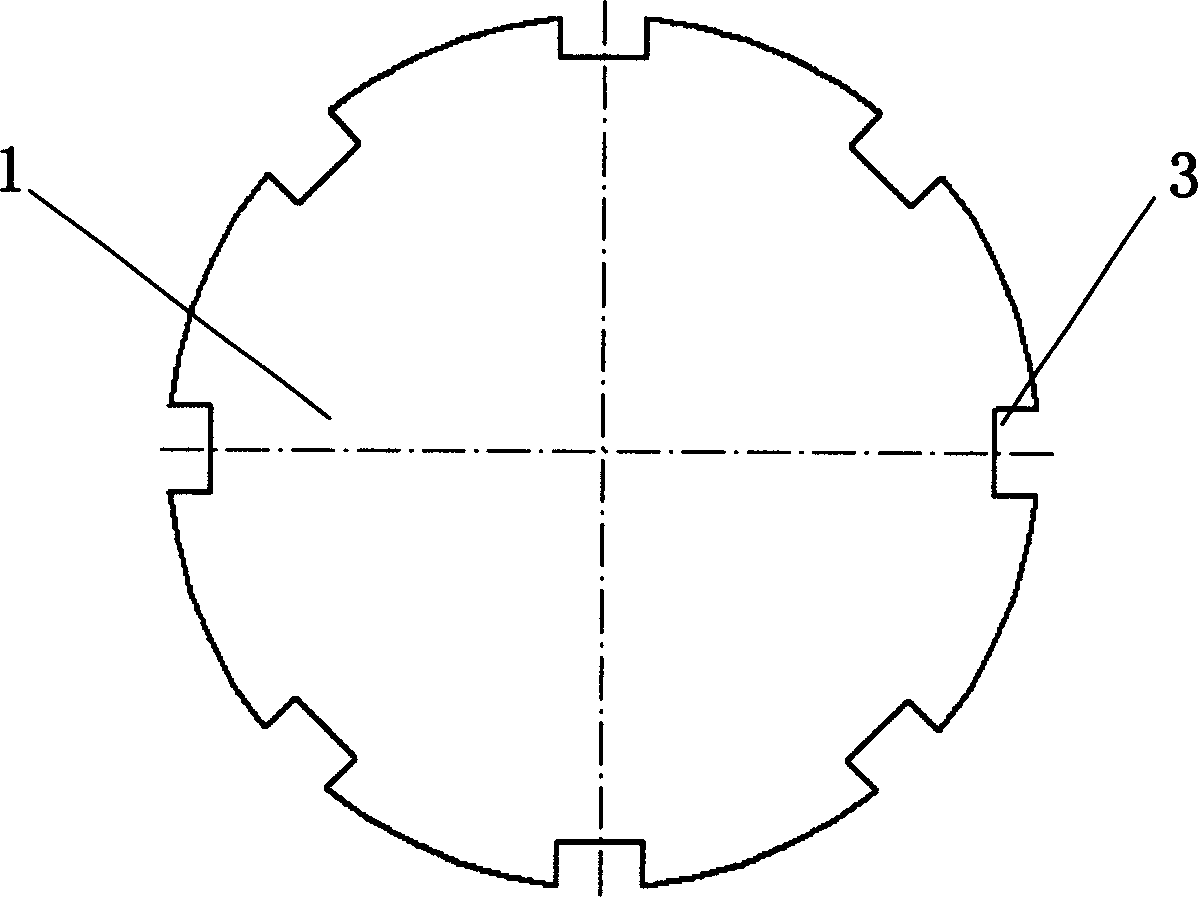

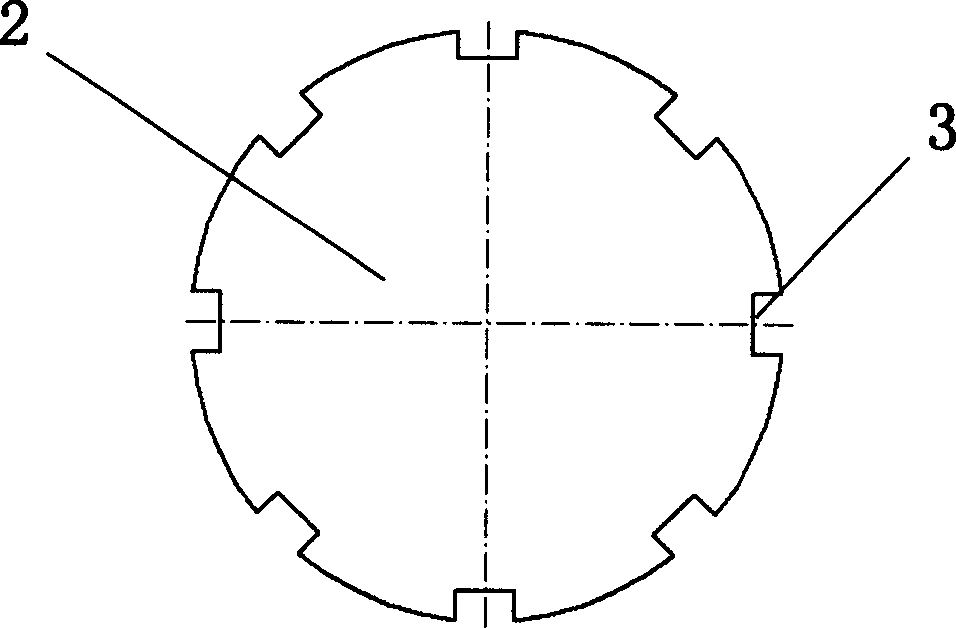

[0013] In the present embodiment, several grooves (3) are evenly distributed on the outer diameters of the large cake mold (1) and the small cake mold (2), and the effect of the grooves (3) is to facilitate the winding of the coil from the large and small molds (1, 2) lift up, the depth of the groove (3) should ensure that the wound coil can be lifted smoothly from the big and small molds (1, 2). The size gap between the large cake mold (1) and the small cake mold (2) is determined according to the capacity of the transformer.

[0014] The present invention mainly realizes through following process:

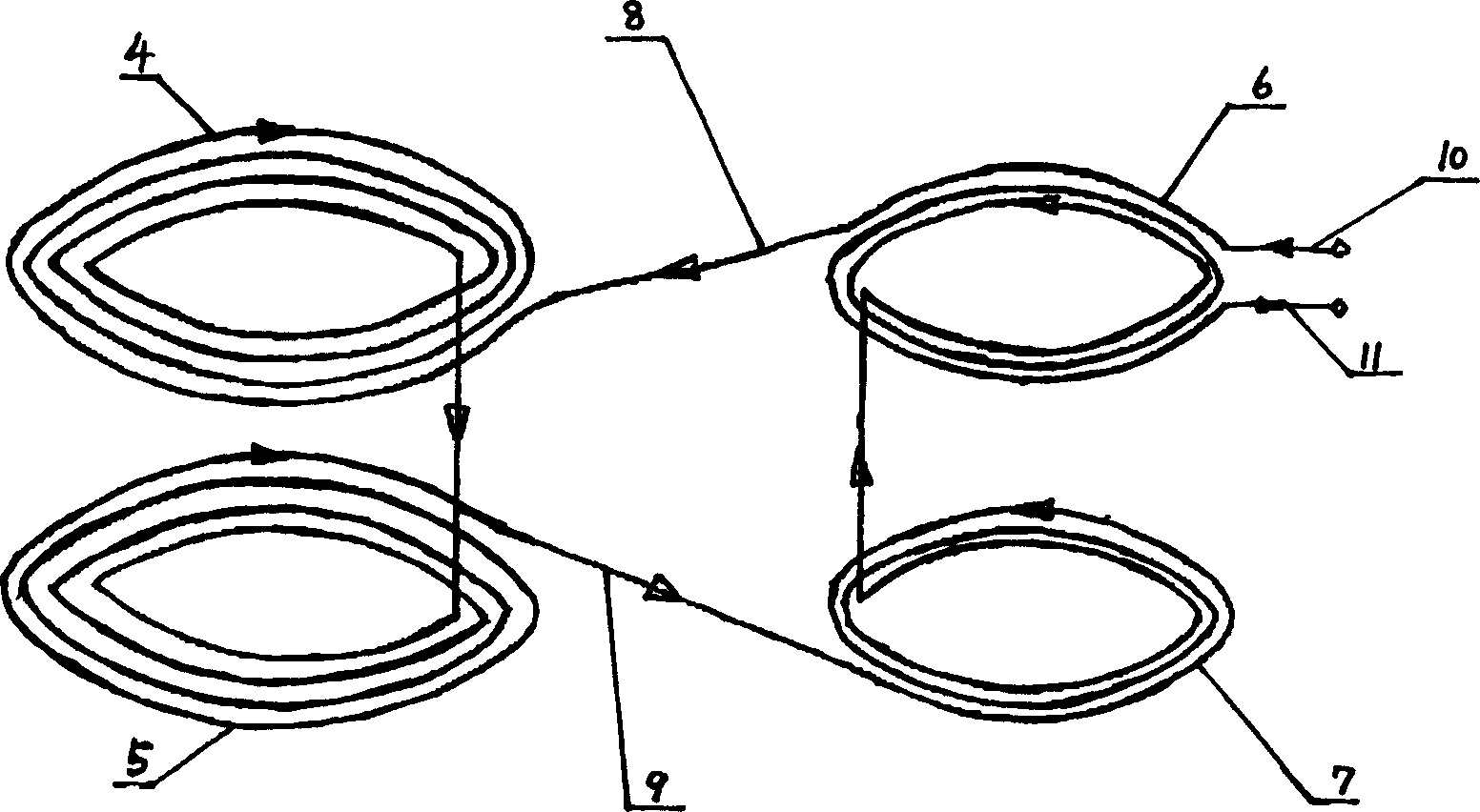

[0015] First, fix the pancake mold (1) and the small pancake mold (2) reliably, and the coil starts to wind up from the lead-out line I (10) on the pancake mold (2) during winding, and the arrangement of the wires adopts a double helix arrangement, that is, The wire is wound on the flatbread mold (1) through the transition line I (8), the upper section (4) of the flatbread coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com