Linear oscillator

An oscillator, linear technology, applied in textile and papermaking, papermaking, paper machine wet end, etc., can solve problems affecting the continuity of papermaking production, save maintenance time, improve service life, and avoid failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

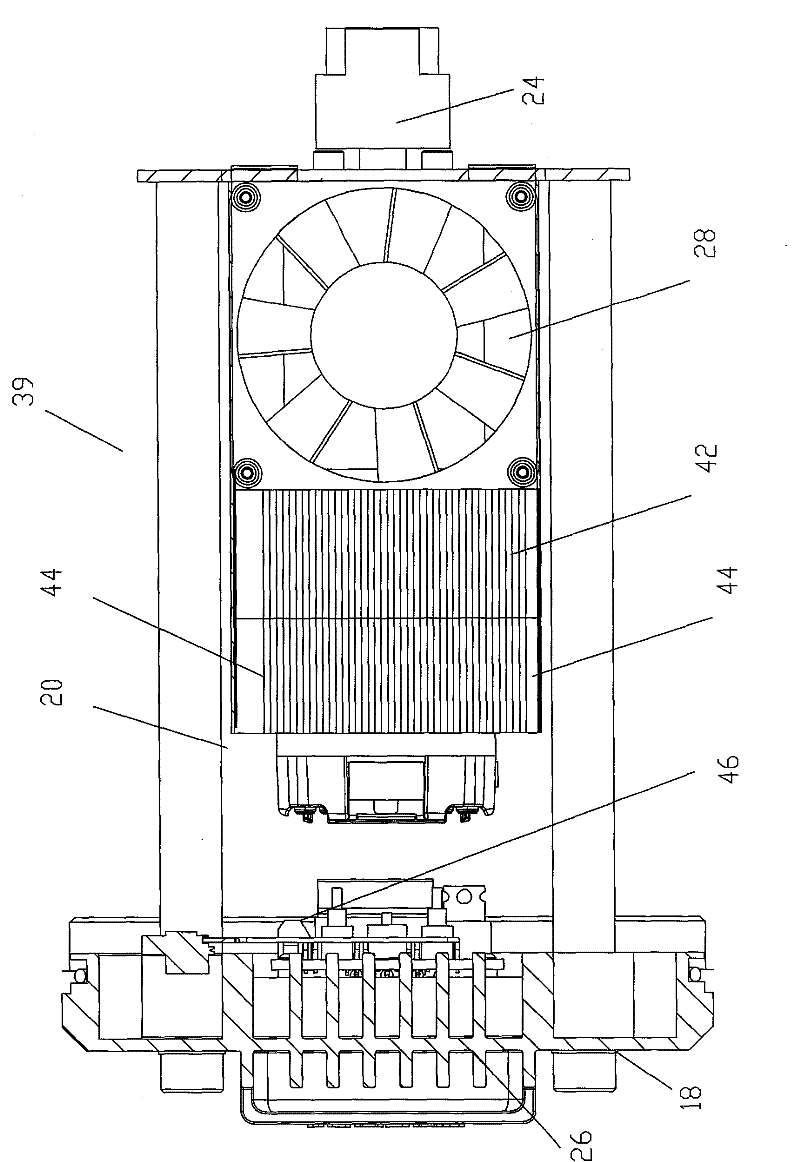

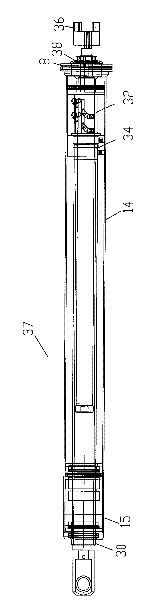

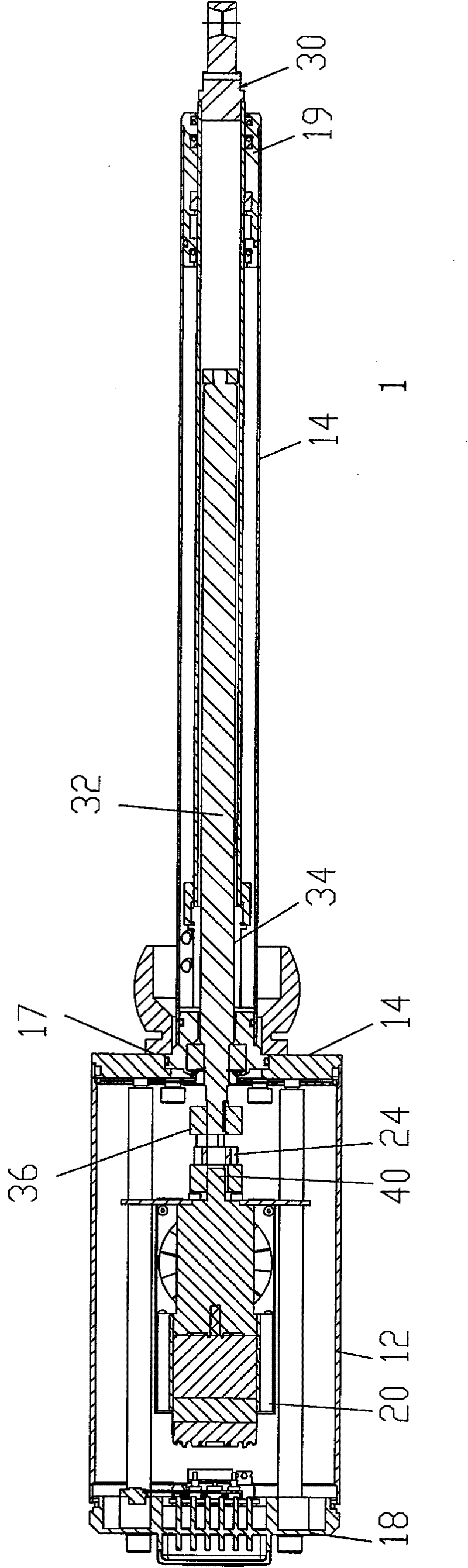

[0024] The structure involved in the patent of the present invention is as figure 1 , 2 , 3 shown.

[0025] The oscillator consists of two independent standard modular components (barrel body assembly 37 and drive system 39) and an electrical control system. The barrel assembly 37 converts the rotary motion of the motor into the reciprocating linear motion of the output shaft through the ball screw mechanism. The drive system 39 provides a powerful power source for the oscillator. The electrical control system precisely controls various technical parameters such as stroke size and swing speed of the swing. The components and functions of each component are introduced in detail below.

[0026] In order to get rid of the method that the traditional swing is controlled by a polarity changeover switch and a control rod, and the fatal influence produced by this method on the swing. The electrical control system of the oscillator adopts a new design method. The motor 20 adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com