Cleaning device for tailor's machine

A cleaning device and cutting machine technology, which are applied in the cutting of textile materials, cleaning methods using gas flow, cleaning methods and utensils, etc., can solve the problems of polluting the use environment, time-consuming and laborious, and achieve extended connection time and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

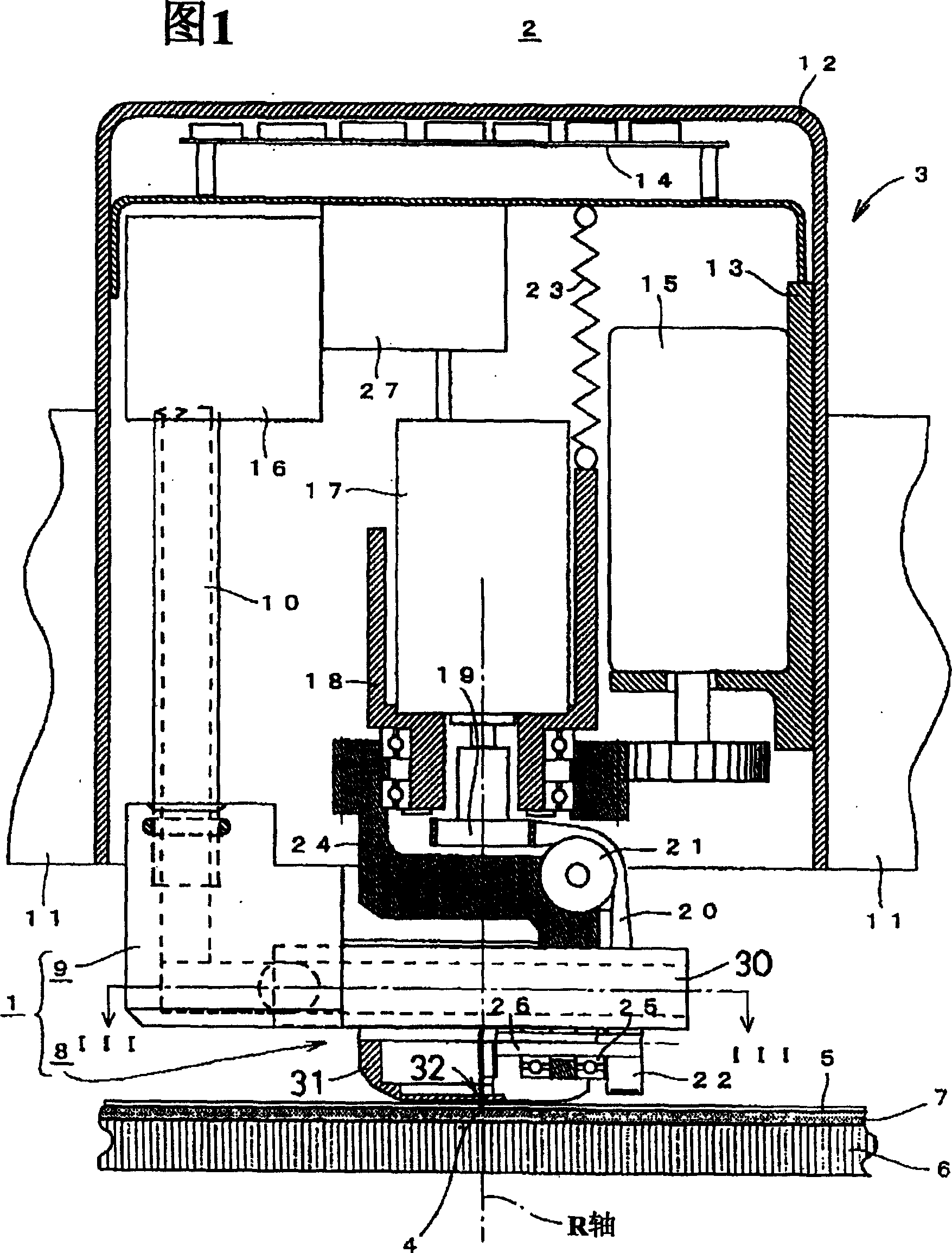

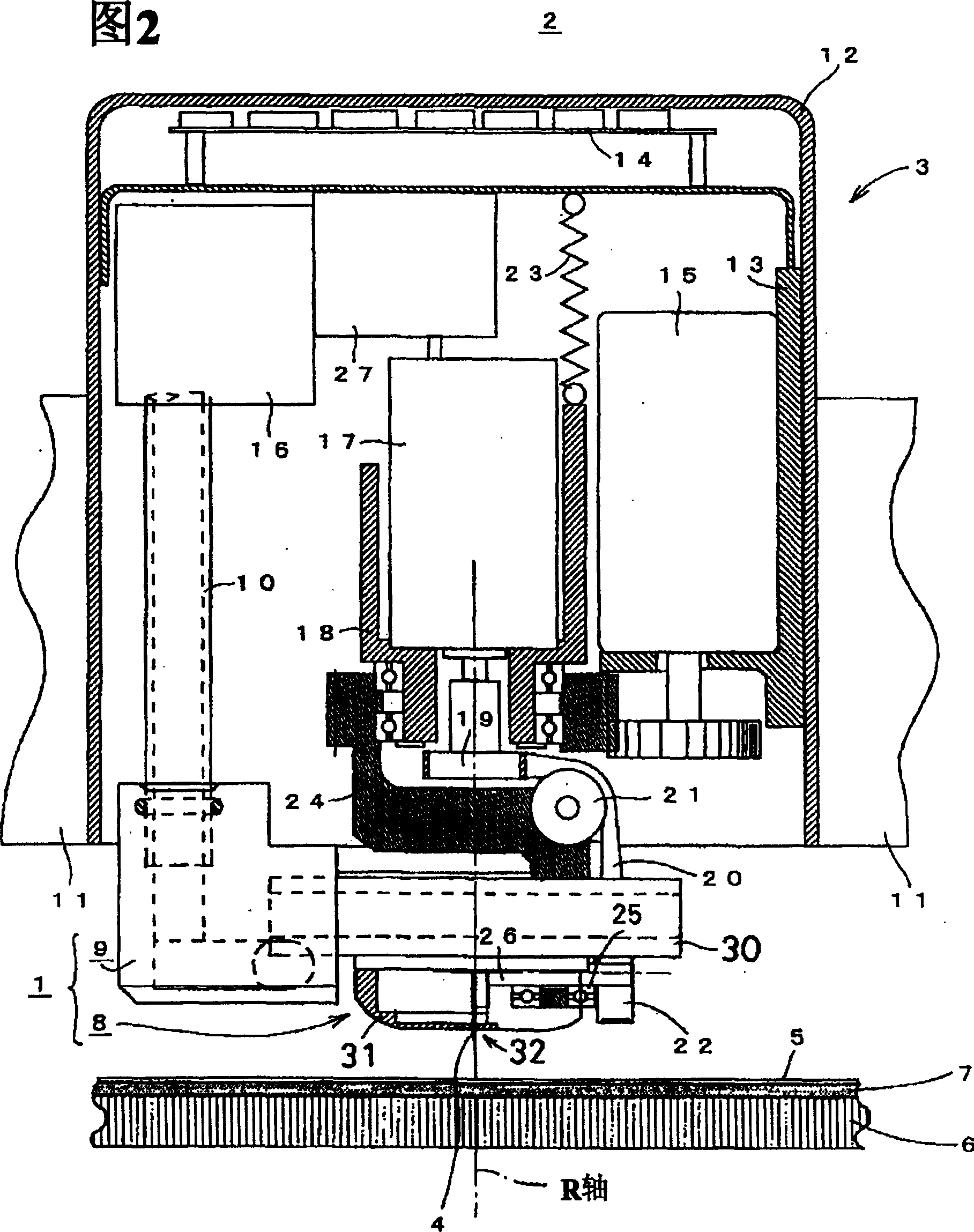

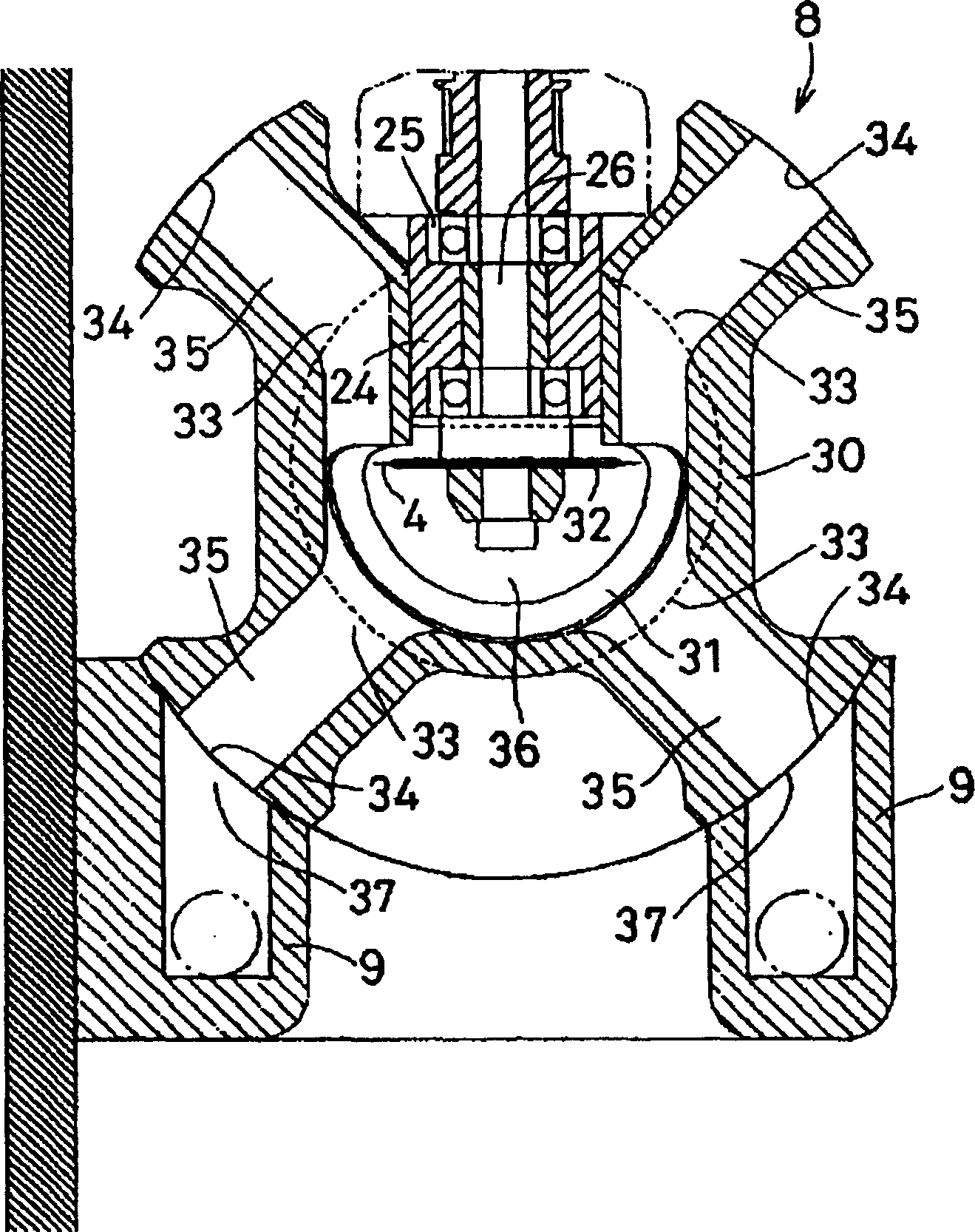

[0032] FIG. 1 shows a schematic configuration of a cutting head 3 of a cutting machine 2 having a cleaning device 1 according to an embodiment of the present invention. The cutter head 3 has, as the cutter blade 4 , a circular blade that rotates to cut the outer periphery of the sheet material 5 . A sheet material 5 as a material to be cut is placed on a cutting table 6 . The cutting table 6 is held by vacuum suction from below so that the cut sheet material 5 is not displaced. When the air permeability of the sheet material 5 is high and the retaining force obtained only by the sheet material 5 is not large enough, an air-impermeable synthetic resin film is used to cover the surface of the sheet material 5 . This air-impermeable film is cut by the cutter 4 together with the sheet material 5 . In order to use the cutting knife 4 to cut the sheet material 5, the cutting knife 4 needs to penetrate the sheet material 5 completely, and the tip of the knife needs to go out from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com