Packaging method for semiconductor image sensing module

A technology of image sensing and packaging method, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of poor heat dissipation, large size, poor thermal conductivity of plastics, etc. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

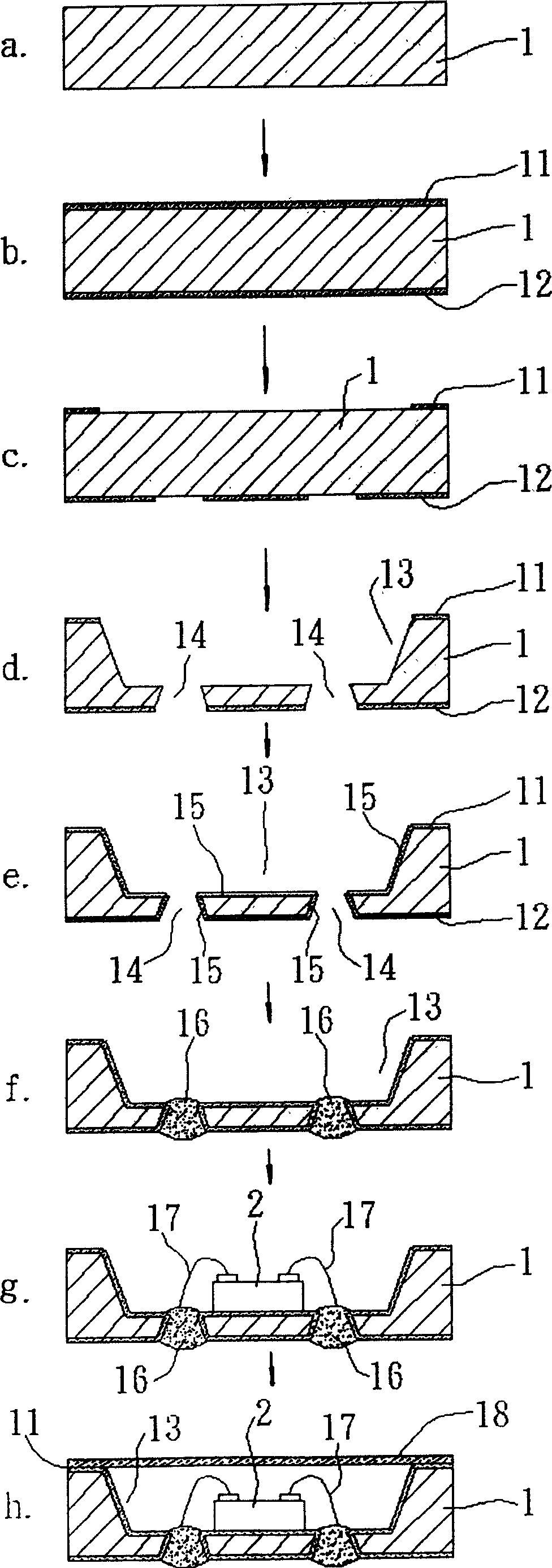

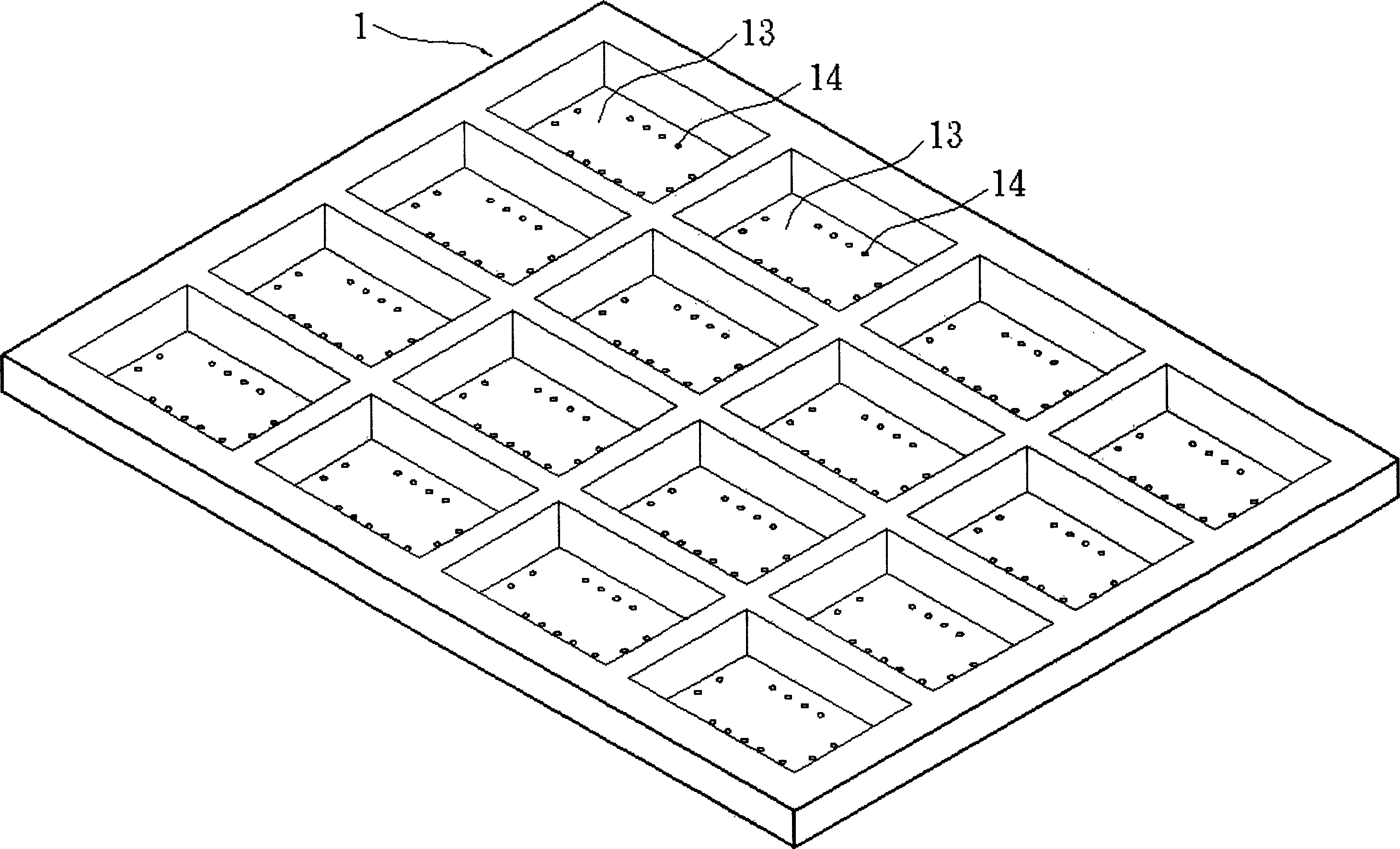

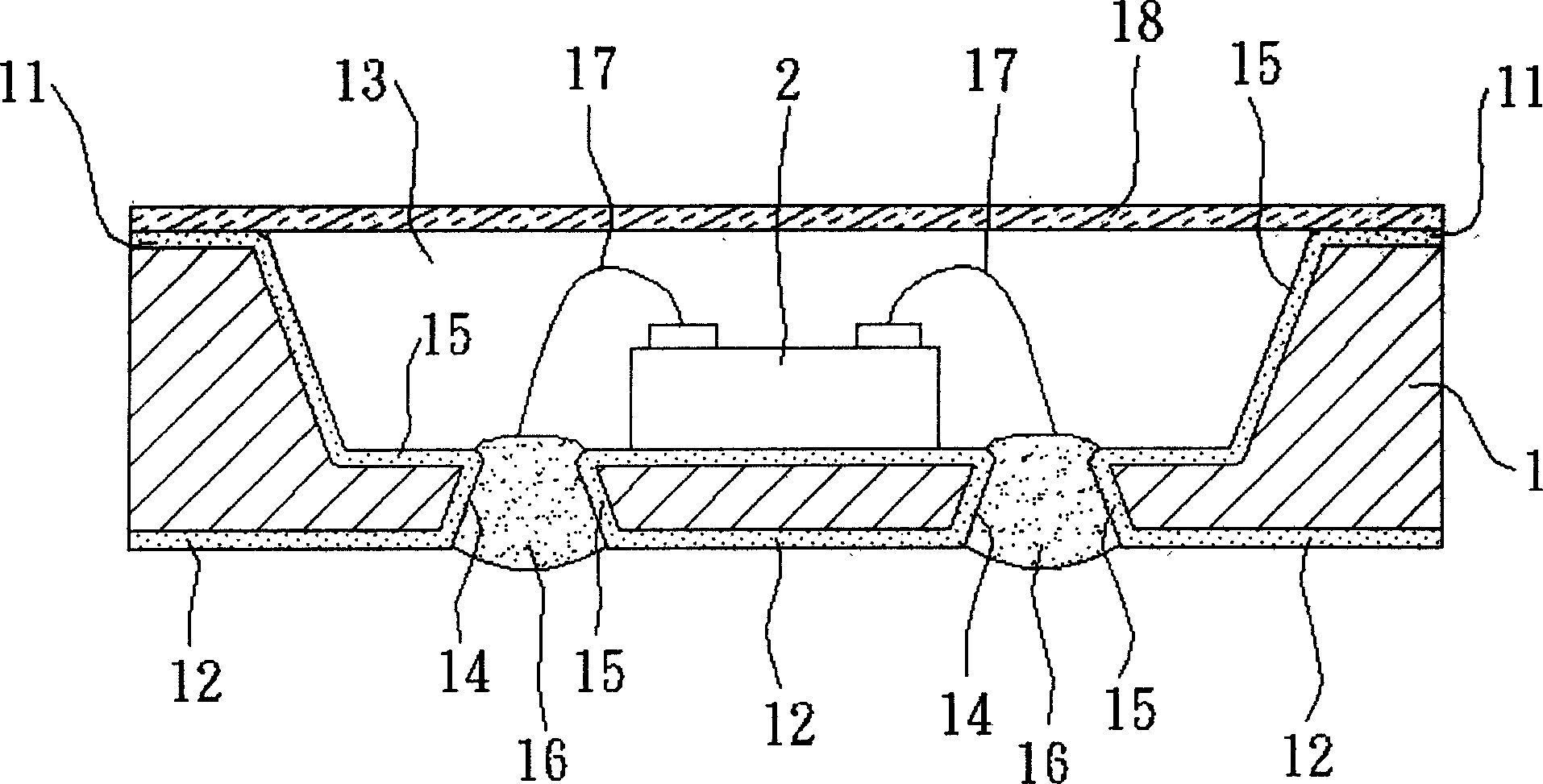

[0046] see figure 1 and FIG. 4, the packaging method of the semiconductor image sensing component of the present embodiment,

[0047] It includes the following steps:

[0048] a. Preparation:

[0049] A single crystal silicon chip is selected as the process substrate 1 .

[0050] b. Form a protective layer:

[0051] The substrate 1 is placed in a furnace tube, and a layer of silicon dioxide is grown on both sides of the substrate 1 by thermal oxidation or a layer of silicon nitride is grown by deposition as a protection layer 11 , 12 .

[0052] c. Define the etching hole:

[0053] Part of the protective layer is removed on both sides of the substrate 1 by BOE wet etching or RIE dry etching by lithography process, so that the surface area of the substrate 1 to be etched subsequently is exposed.

[0054] d. Etching:

[0055] Utilize the KOH or TMAH anisotropic wet etching method to etch the parts without the protective layers 11 and 12 on both sides of the substrate 1, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap